G weike волоконный лазерный станок для резки LF 1325LC аэрозольная краска металлических и неметаллических материалов цена

- Категория: >>>

- Поставщик: Gweike Tech Co. Ltd.Gweike Ltd.

Сохранить в закладки 60818761490:

Описание и отзывы

Характеристики

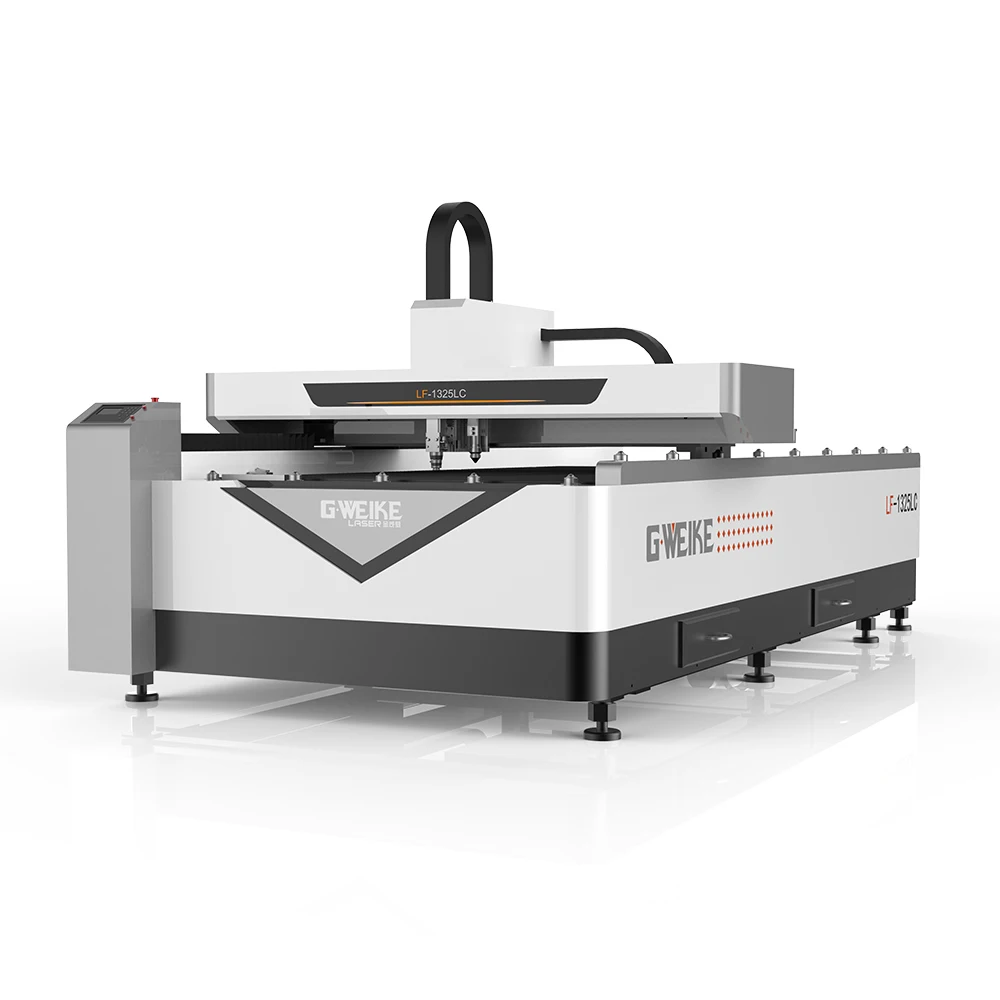

G-weike fiber laser cutting machine LF-1325LC for metal and non-metal price

specification of G-weike fiber laser cutting machine LF-1325LC

1.G-weike fiber laser cutting machine LF-1325LC Whole Machine welded bed structure,Stable performance,could ensure the stable operation of equipment.

2.After 650℃ high temperature heat treatment Machine bed, adopt large Gantry milling accuracy process, ensure machine bed stability and smoothness.

3.Operating system, man-machine interface, easy to operate

4.High quality, high efficiency fiber laser producer. low processing cost and energy conservation and environment protection

5.Servo drive,The structure of the machine tool adopts rack and pinion drive,Ensure equipment high speed , high accuracy, and high reliability

LF1325LC fiber co2 laser cutting machine is the first model in the world with fiber laser source and co2 glass tube in one machine produced by GWEIKE , it is an all-around model widely used for cutting metal and nonmetal materials.

the configuration of G-weike fiber laser cutting machine LF-1325LC

*Au3tech cutting head

*Japan YASKAWA Delta Taiwan TBI ball screw drive

*Taiwan HIWIN square rail

*French Schneider electronic parts

*Au3tech operation system

*Water cooling machine

*Three years warranty

| Machine Model | LF1325LC |

| Working Area | 2500mm*1300mm |

| Laser Power | 300w 500w Fiber laser source 150w CO2 laser source |

| Cutting Thickness | 20mm (Depend on materials) |

| X/Y Axis Positioning Accuracy | ±0.03mm |

| Max.Running Speed | 30m/min |

| Operating Temperature | 0℃-40℃ |

| Transmission | Imported TBI ball screw |

| Specified Voltage and Frequency | 380V 50Hz/60Hz/60A |

the application of metal & nonmetal laser cutting machine for price:

Jinan G.Weike Science & Technology Co., Ltd is established in July 2004. It is a modern enterprise in combination of researching, producing and selling on Optics, Mechanics and Electronics. Our company is one of the biggest manufactures for small and medium laser cutting machine, recently the company owns 150 employees, more than 500 square meters of researching and office space, more than 26000 square meters of factory space. The total sales quality is more than 10000 sets since the company established and along with the production scale expanding, the annual sales quality has achieved more than 3000 sets now. Our products are sold to USA, Canada, Australia, Europe, South east Asia, Africa etc. more than 80 countries and areas, and supply OEM service for more than 10 manufactures.

Warranty and service

Three years warranty for machine. English technical to door service.

English manual and Video CD for machine using and maintenance.We offer free training in our factory,

welcome to visit and learn more about our machines.

Free accessories :Software ,manual, book, cd videos, USBcontrol

1.Pre-sales service

A. Free sample making

For free sample making/testing, please send your samples or products CAD Graphics to our company in China. Try before you buy.

B. Progressing Solution Design

According to customer’s product processing requirement, we can design the unique solution that supports higher manufacturing efficiency and better processing quality for customer.

2.After-sales service:

Training to install(3options):

A. We will supply the machine with training video and user's manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by e-mail, telephone/MSN/ICQ and so on, when you meet some problems of installation, using or adjusting.

B. You can come to our factory for training. Gweike will offer professional guide. Direct and effective face-to-fdays.ace training. Here we have assembled equipments, all sorts of tools and testing facility,we will also provide accomadation during training period.

1. What material can fiber laser machine cut?

Stainless steel, carbon steel, mild steel, galvanized steel, aluminum, copper, brass and other metal sheet and pipe.

2. What's the max. cutting thickness?

Cutting thickness is related to laser power.

300W: 1.5mm stainless steel, 4mm carbon steel

500W: 3mm stainless steel, 6mm carbon steel

1000W: 5mm stainless steel, 12mm carbon steel

2000W: 10mm stainless steel, 18mm carbon steel

3. How long will it take to learn to operate a laser machine?

If you are able to use some basic graphic design software, it will only take a few hours to master the operation. You just need to do some simple tests on different processing materials to know how to set the correct speed and laser power.

Похожие товары

Лазерный резак 6090 1390 1325 CO2 лазерная гравировальная машина для резки золота дерева MDF акриловая немаркировка Портативный 100 ватт 150 Ватт

1325 металлические и неметаллические лазерные Режущие Машины для лазерной резки волокна Co2

Лазерный резак серии 3015D 3050x1530 мм новое состояние лазерной резки металла из нержавеющей стали гравировка лазерная AI

Станок для лазерной резки тонкого металла лазерный гравировальный станок 150 Вт резак и неметалла 1325

100 Вт ювелирные изделия лазерный резак лазерная гравировальная машина золото серебро и для резки цена

Foster 150 Вт 180 300 Смешанная металлическая сталь акриловая ПВХ 1325 СО2 лазерная резка резак гравировальный станок цена

Co2 лазерный гравер режущий станок 80 Вт 100 130 по металлу для резки 9060 металла

Новые поступления

Новинки товаров от производителей по оптовым ценам

![0GVXD1}F{E37T}U~6SNK]T](http://sc01.alicdn.com/kf/HTB1ZrmqXzDuK1Rjy1zj762raFXaU/592359/HTB1ZrmqXzDuK1Rjy1zj762raFXaU.png)