Горячая продажа MIG TIG пила автоматическая колонка и стрелы сварочный

- Категория: Other Welding Equipment >>>

- Поставщик: Zhengzhou Yueda Technology Equipment Co. Ltd.

Сохранить в закладки 60831555995:

Описание и отзывы

Характеристики

Hot sale MIG TIG SAW automatic column and boom welding machine

Product description for Hot sale MIG TIG SAW automatic column and boom welding machine:

Welding manipulator also called as column and boom welding machine which combine with welding rotator and welding positioner to become the dedicated automatic welding device for welding structure parts’ internal and external circular seam, fillet weld, inside and outside longitudinal seam and has different structure forms such as fixed type, rotary type, versatile position type, etc.

And according to user’s requirements, we also can choose structure or equipped with different kinds of welding machines and adding tracking, swing, monitoring, solder recycling& conveying functions. The welding manipulator is widely used for many kinds of industries such as pressure vessel, cooling device, power plant construction, metallurgical construction, engineering machinery, shipbuilding, roll surfacing welding, petrochemical construction, etc.

Advantages and Features for Hot sale MIG TIG SAW automatic column and boom welding machine:

1. Column and beam with steel profile structure, planar guide rail design, which has good rigidity and low structural deflection.

2. Beam’s lifting with AC motor constant speed operation, steady lifting with constant speed.

3. Beam’s stretch with AC variable frequency stepless speed regulation, constant torque output, steady speed, guide rail is 45# steel, stress reduction treatment after welding, plane forming, high intensity, good stability and guarantee no deformation long time.

4. Beam’s stretch with gear and rack transmission, high transmission accuracy, steady operation, speed digital display and can be preset.

5. Beam’s lifting, beam’s stretch, trolley advance and retreat all equipped with electrical and mechanical double protection device.

6. Adopt high quality slewing bearing, flexible rotation, long lifespan.

7. Adopt plastic towing wiring technology, durable, convenient, beautiful and safe.

Control station and hand operator form remote control method, adopt computer control technology, all welding parameters digital display and can be preset, flexible operation and control station reserved linkage interface which can be interconnected with other products. Hand controller in your hand can make remote control easily for welding manipulator, welding center and other structure, and make real-time control for welding process.

Main technical parameters for Hot sale MIG TIG SAW automatic column and boom welding machine:

| Welding manipulator/Welding column&boom main parameters | ||||||||

| Model | CZ2X2 | CZ3X3 | CZ4X4 | CZ5X5 | CZ6X6 | CZ8X8 | CZ10X10 | |

| Boom effective lifting range(mm) | 2000 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | |

| Boom effective extanding range(mm) | 2000 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | |

| Guide rail form | V type rail | Rectangular rail | ||||||

| Boom max. height(mm) | 2210 | 3360 | 4365 | 5415 | 6460 | 8720 | 10750 | |

| Boom min.height(mm) | 210 | 360 | 365 | 415 | 460 | 720 | 750 | |

| Total height(mm) | 2880 | 4395 | 5455 | 6725 | 7825 | 10585 | 12700 | |

| Total height with rotary device(mm) | 2955 | 4480 | 5550 | 6820 | 7920 | 10680 | 12830 | |

| Total height with trolley(mm) | 3200 | 4790 | 5860 | 7135 | 8235 | 11095 | 13340 | |

| Lifting speed(mm/min) | 1000 | |||||||

| Extending speed(mm/min) | 120-1200 | 100-1000 | ||||||

| Trolley moving speed(mm/min) | 2000 | 800 | ||||||

| Guide rail inner gauge(mm) | 1000 | 1500 | 1750 | 2000 | 2000 | 2230 | 2500 | |

| Column rotation | degree(°) | ±180 | ||||||

| speed(r/min) | 0.5 | 0.5 | 0.14 | 0.14 | 0.14 | 0.14 | 0.14 | |

Notice: customized welding column boom is available according to clients' requirement.

Welding clumn and boom welding manipulator production picture for reference:

Our main products are: welding manipulator /column boom series, welding rotator/turning rolls series, welding positioner / turntable / worktable series, pipe straight seam welder, automatic tank welding machine, 6 axis welding robot, robot welding station, surfacing cladding machine series, pipe inner seam welding machine, Electricity & Telecommunication tower rod production line, wind tower production line, special tanker production line, pressure vessel production line, tower rod production line, digital inverter MIG/TIG/Manual Arc welders , plasma cutting machine series , painting production line, etc.

Our products are widely used in tower rod manufacturing, petrochemical, pipeline, pressure vessel, steel structure, mechanical manufacturing connection, power engineering, automobile manufacturing, wind tower manufacturing and other industries. Some products exported to Europe, the Middle East, Southeast Asia, USA, Australia, Mexico, Brazil, Africa and other places. Product quality and performance by the user's praise and trust.

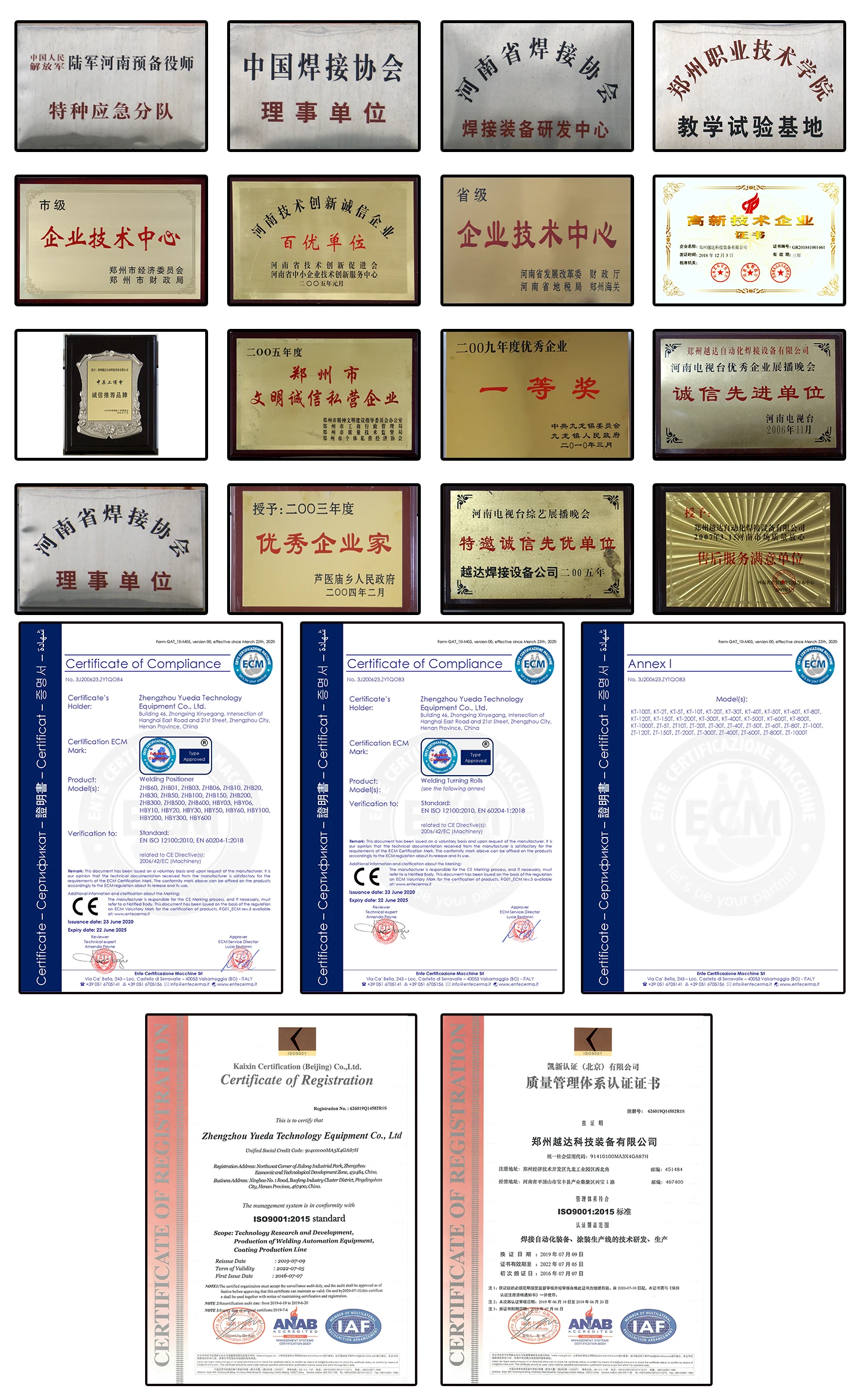

Yueda Technology is rated as Henan Provincial R & D center, which has four enterprise research institutes: the Welding Industry Institute, Mechanical Design Institute, Automation Control Institute, Painting Technology Institute. Long-term commitment to welding and cutting auxiliary tools, welding and cutting automation equipment and various non-standard production line research and development.

We are looking forward to your visit and cooperation, one stop solution is ready for you. We will be a reliable partner of you!

Our services

1. Professional one stop solution and suggestion according to clients'requirements.

2. Professional package and shipping service.

3. Free spare parts and maintenance during warranty period, and lifelong guiding service through email and telephone.

4. Technical engineers are ready to go abroad for installation, trainning and maintenance.

5. Quick response for enquiry and afterservice.

6. Customized service,OEM&ODM service are available to meet clients' different requirements.

Professional package and shipping service, machines packaged by exporting wooden case or naked package put into shipping containers according to machine dimension. And customized package is available to meet clients' special requirements.

FAQ

Q: What's the MOQ?

A: 1 set.

Q: Are we a trading company or a manufacturer?

A: We are manufacturer with 20 years production history.

Q: What’s your payment terms?

A: Negotiable, but usually L/C and TT.

Q: Can machines be customized?

A: Yes, OEM and ODM are available.

Q: How can you guarantee the product quality?

A: We have strict quality control system in the production process and we welcome clients come to visit us to check the product quality before delivery.

Q: How long is the warranty period?

A: One year.

Q: How long is your delivery time?

A: Usually within 40 days since we received deposit payment, and some standard models of machines in stock.

Похожие товары

Резка запасных частей резка Сварочная горелка

SUGON 861DW горячего воздуха SMD паяльная станция 1000 Вт

Автоматические алюминиевые трубы из нержавеющей стали аргоновый сварочный робот ручной

С изолированным затвором (IGBT) Пульс WSM-400P WSM-400 WSME-400 WSEM-400 WSME-400P WSEM-400P переменного тока/постоянного тока с квадратными каблуками волновой импульсный TIG сварочный

Машина для производства сборных арматурных клетки длиной 16 м стальная арматурная арматура машина

Futan нетканый мешок ручки сварочного аппарата

Лидер продаж высокочастотный индукционный автоматический сварочный аппарат 18 кВт с сертификатом

Новые поступления

Новинки товаров от производителей по оптовым ценам