Крупногабаритный литейный завод с мощными обрабатывающими возможностями (25 лет опыта 20000 тонн)

- Категория: >>>

- Поставщик: Ningbo Qianhao Metal Product Co. Ltd.Ningbo Ltd.

Сохранить в закладки 60838104004:

Описание и отзывы

Характеристики

A large-scale Foundry With Powerful Machining Capabilities(25 years experience,20,000 tons capacity)

1. Company Profile

2. Operating Structure

3. Foundry Overview---Huawei Foundry

|

4. Sheet Metal Overview---Qianhao Machinery

|

5. Machining Overview---Qianhao Metal

| Established in 2009 13,500 SM under roof 215+ employees Advanced high and CNC equipment 50+ vertical and horizontal machining centers Some abroad brand equipment - Doosan 80+ CNC machines (lathe, milling, drilling ) 80+ additional supporting equipment 5 welding robots | Product Offering: Machined profiles( rods, tubes etc.) Machined steel castings Machined stainless steel castings Machined iron castings Machined aluminum castings Machined forgings Machined cutting plates and sheet metal Welded parts Assembly parts |

6. Headquarter Overview---Longxing Machinery

|

7. Expansion 2025---Qianhao Industry

|

8. Casting

| Our four casting processes is able to meet customer's wide range of needs for castings of different grades and qualities. Covering different grades of casting precision (CT6-8) surface roughness (Ra6.4-25um) weight range (0.1-500kgs) |

9. Lost Wax Casting---Manufacturing Process

10. Lost Wax Casting---Key Casting Equipment

11. Lost Wax Casting Process Technology Overview

| Casting Process | Lost Wax Casting (Investment Casting) |

| Material Range | carbon steel, alloy steel, stainless steel |

| Material standard | GB, ASTM, AISI, DIN, BS, JIS, NF, AS, AAR |

| Max Linear Size | 1000mm; Max Diameter Size: 600 mm |

| Min Thickness | 3mm |

| Casting Weight Range | 0.10~80kgs |

| Casting Dimension tolerance | CT6-CT8 |

| Casting Surface Roughness | Ra6.4-12.5um |

| Industry Experience | rail, automobile & truck, construction & mining equipment, forklift, agricultural machinery, shipbuilding & marine, petroleum industry, construction, valve and pumps, electric motors, hardware, power equipment |

12. Lost Foam Casting

13. Shell Moulding

14. Machining

| Starting from machining and dedicated to machining for 30 years, Qinhao is matchless regardless of technology, equipment and capacity in the industry. |

15. Key Machining Equipment

16. Key Machining Equipment/Machine List

| Horizontal Machining Center(4 Axis): 2 | CNC Milling: 10 |

| Vertical Machining Center(4 Axis) : 49 | CNC Drilling: 5 |

| Turn Center: 1 | Drilling and Tapping Center: 7 |

| CNC Lathe: 35 | Milling Machine: 6 |

| Turning Milling Center: 11 | Drilling Machine: 5 |

| Total 200+ Various Machining Equipment | |

17. Machining Specification

| Machining Material Range | arbon steel, alloy steel, stainless steel, cast iron, aluminum alloy, copper alloy |

| Main machines | four-axis horizontal machining center, four-axis vertical machining center, CNC milling machine, CNC lathe, turning and milling center, drilling and tapping center, CNC drilling machine, multi-station special machine |

| Machine Accuracy positioning accuracy | ±0.004mm, repeatability±0.003mm |

| Maximum Cutting Diameter | φ1000mm |

| Maximum Machining Length | 1800mm |

| Maximum Travel (x,y,z axis) | 1800x850x700mm |

| Maximum Spindle Speed | 12000 r/min |

| Maximum Workpiece Weight | 2500kgs |

| Machining Surface Roughness Range | Ra0.8 ~ 6.3um |

18. Cutting Plate & Sheet Metal, Welding

19. Quality Control---Credentials

20. Test Facilities Capabilities

1. Chemical analysis |

| 2. Metallography |

| 3. Tensile strength |

| 4. Yield Strength |

| 5. Elongation rate |

| 6. Shrinkage rate |

| 7. Impact test |

| 8.Harness test |

| 9. Dye Penetrant |

| 10.Radiography (RT) |

| 11.Magnetic Particle (MT) |

| 12.Ultra-Sonic (UT) |

| 13.Surface roughness test |

| 14.Microscopic Measurement |

| 15.3D Scanning |

| 16.CMM |

21. Key Testing Equipment

22. APQP and Inspection Report:

APQP-Casting

|

APQP-Machining

|

Sheet Metal Welding Quality Management Documents

|

Other Quality Document

|

Inspection Report

|

23. Competition advantages

| Advantages 1:High Engineering and Technical Capability |

|

| Advantages 2: Advanced Inspection Equipment,Process & Strong Quality Assurance Capacity |

|

| Advantages3: Great Customer Service |

|

| Advantages 4:Powerful deep-processing capability is core competitive advantage that makes us different from others in the industry. |

|

24. Contact information:

Похожие товары

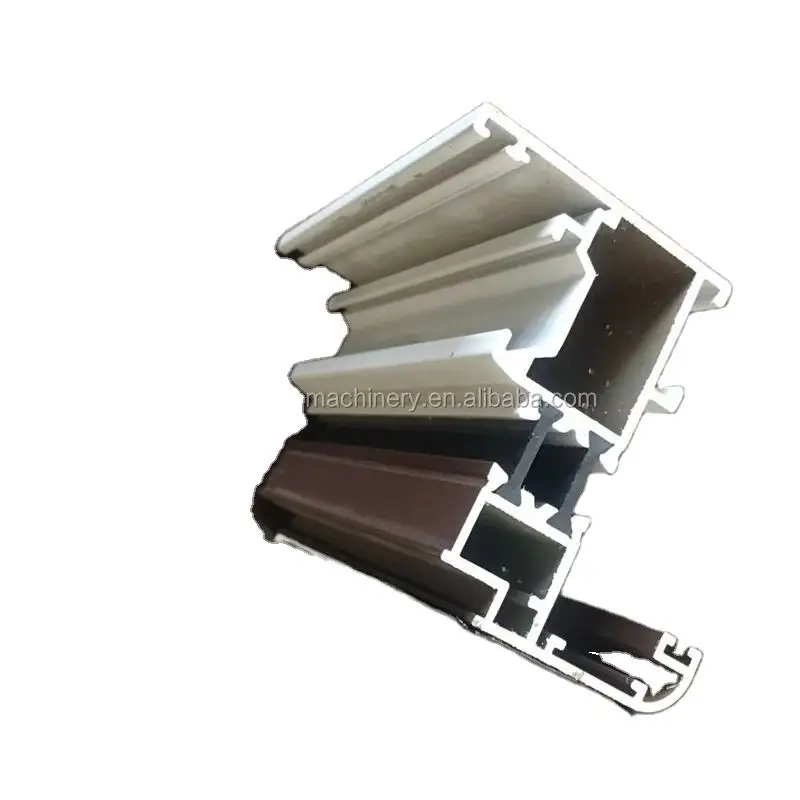

Формование и формование металлического инструмента алюминиевый профиль экструзионный анодированный экструдированный пластический деформационный материал для обработки поверхности

DSN OEM полые профили луча для оснастки алюминиевый профиль экструзионный анодированный экструдированный пластический деформационный материал обработки поверхности

OEM литой алюминиевый профиль европейский стандарт анодированная отделка обработка T6 Costom экструзия порошкового покрытия

Электроизоляция Коррозионностойкий профиль штамп алюминиевая Экструзионная анодированная экструдированная обработка поверхности

Пластиковые пресс-формы для литья под давлением

Сплав ISO 4080 4040 7070 6063 T5 литой алюминиевый профиль Европейский анодированный финиш T6 обработка Costom порошковое покрытие Экструзией

Профиль для обработки поверхности алюминиевая Экструзионная анодированная экструдированная обработка пластическая деформация

Новые поступления

Новинки товаров от производителей по оптовым ценам