Цилиндрический карбид вольфрама

- Категория: >>>

- Поставщик: Guanghan N&D Carbide Co. Ltd.

Сохранить в закладки 60839943089:

Описание и отзывы

Характеристики

Application:

Main used for:

*Cleaning trimming,veining and weld joint of casting, forging and weldment.

*Finishing all kinds of metal molds.

*Impeller passage of finishing processing.

*A variety of mechanical parts chamfer,round and groove processing.

*Inner hole surface of machinery parts finishing.

• Generally use with handheld electric or pneumatic tool drive.

• Be careful about mounting and handling the burr correctly, the handle must be clamped when it is running.

• Only at high speed,can carbide rotary burrs show their remarkable performance.

• Recommended operating speed should between 3800-7500 surface cm per minute.

Type:

Features:

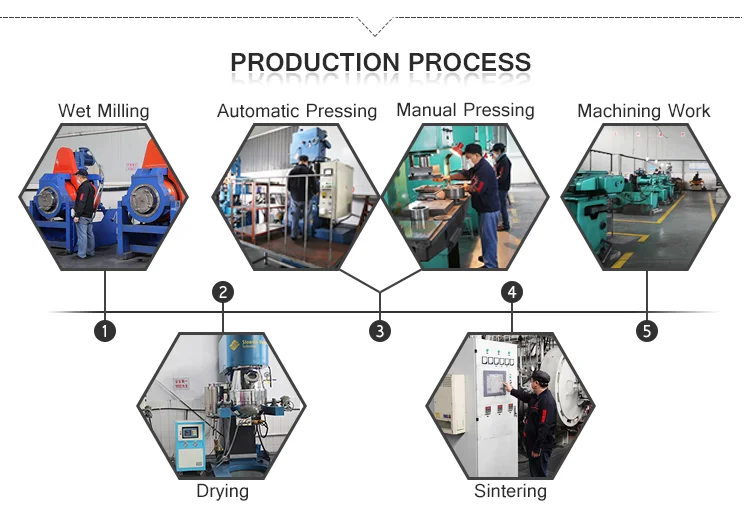

1.High Quality: Sintered and machined from 100% raw tungsten carbide powder, with good wear resistance.

2.High Performance: Good processing quality, high finish. Can be processed into a variety of high-precision shape mold cavity.

3.Long Life: 10 times working life than HSS and 50 times than small emery wheels. Increasing productivity of several 10 times than using common hand tools.

4.Easy to grasp and use, safe and reliable.

Cutting Type | Double Cut | Single Cut | Aulminium Cut | Fine Cut |

Applications | Efficient stock removal―deburring, finishing and cleaning. | Medium stock removal―deburring, milling, finishing and cleaning. | Heavy stock removal―deburring, milling, machining and cleaning. | Light stock removal―fine deburring and fine finishing. |

Cutting Material | Ferrous metals, non-ferrous metals. | Non-Hardened steel>45 HRC Hardened steel>45 HRC: stainless steel. High temperature resistant matals:nickel, cobalt, titanium. Non-ferrous light metals: brass, copper and zin. | Non-ferrous metals: alumium alloy, plastics. | Hardened>45 HRC |

Founded in 2004, Guanghan N&D Carbide Co Ltd is one of the fast growing and leading manufacturers in China working specifically with super hard metals. We specialize in producing a wide range of wear part for oil & gas drilling, flow control and cutting industry.

From the selection of premium raw materials to the precision finishing and polishing of complex parts,ND performs all process steps. ND Carbide also offers a full range of carbide grades in both cobalt and nickel binders. These include micro grain grades for applications requiring exceptional combinations of wear resistance and tensile strength, hardness for use in highly corrosive environments, and high cobalt binder grades for production tooling applications demanding high toughness and impact strength.

ND Carbide produces all of the carbide covered by the industry standards as well as custom grades to meet special customer requirements. The cemented carbide material are available either as semi-finished blanks or as precision-machined parts.

We are looking forward to have a good cooperation with your esteemed organization!

First,each carbide burr is packed in a separate plastic case.

Second, outside is packed with cartons, usually in cartons size 40*30*20 cm.

Shipping: By DHL, TNT, UPS, Fedex, EMS express. By sea, By air.

Our Service:

1. According to customers' requirements, we can supply OEM &ODM service.

2. Full inspection before delivery, we guarantee all products with high quality.

3. Great efforts have been made for 15 years, over 50 countries' customers already chose us.

4. To make customers buy our products at ease, we accept return of goods with quality problems.

To save your value time, please inform us of the following information:

1. Grade/ give us information of working condition,

our engineers can provide the best solution for you.

2. Type.

3. Dimension.

4.Order quantity.

BSF-5 1/4'' (6.35mm) Shank Dia Tungsten Carbide Rotary Burr for Grinding Machine.

Grinder Cutting Tools Oval Shape Single or Double cut Tungsten Carbide Burr

Abrasive Tool 1/4 Inch Shank Ball Shape BSD-5 Tungsten Carbide Rotary Burr

Похожие товары

Карбид ротационный напильник 6 мм хвостовик оптовая продажа с фабрики Вольфрам используется для роторного ножа барабанного типа

SM карбид вольфрама заусенец заостренный конус двойной резкой вращающейся напильник с 1/4 '(6,35 мм) хвостовиком

10 шт., набор алмазных игл 2x100 мм

Ручные инструменты двойная резка карбида вольфрама роторные файлы карбида набор заусенцев карбида вольфрама Бур

Быстрый легкий острый антикоррозийный ручной инструмент огнеупленные конические поворотные заусенцы из карбида вольфрама

5 шт., Шлифовальная головка из вольфрамовой стали 6x10 мм

10 шт., иглы с алмазным покрытием, 180x5 мм

Новые поступления

Новинки товаров от производителей по оптовым ценам