OEM высокой точности ковки стали C45 Шпоры механизм реечной передачи руля рейка набор

- Категория: Зубчатые рейки >>>

- Поставщик: Luoyang Yujie Industry & Trade Co. Ltd.

Сохранить в закладки 60840962785:

Описание и отзывы

Характеристики

We offer One-stop service From professional engineer team to High-precision CNC processing

We offer One-stop service From professional engineer team to High-precision CNC processing

raw material organization to ensure the good quality. equipment.

processing production and assembly .

The spur helical precision rack and pinion is a special gear with teeth distributed on the strip body. The racks are also divided into straight racks and helical racks, which are paired with spur gears and helical gears respectively; the tooth profile of racks is straight rather than involute (it is flat for tooth surfaces) The equivalent of the circle radius of the indexing cylinder is infinite.

Our company would supply Gear rack,Standard rack, Non-standard rack, Marine rack, Helical rack, Round rack, Port machine rack, Heavy Duty Rack, Curved rack, Mechanical racks for shoes, Construction lift rack etc.

Advantages of gear racks

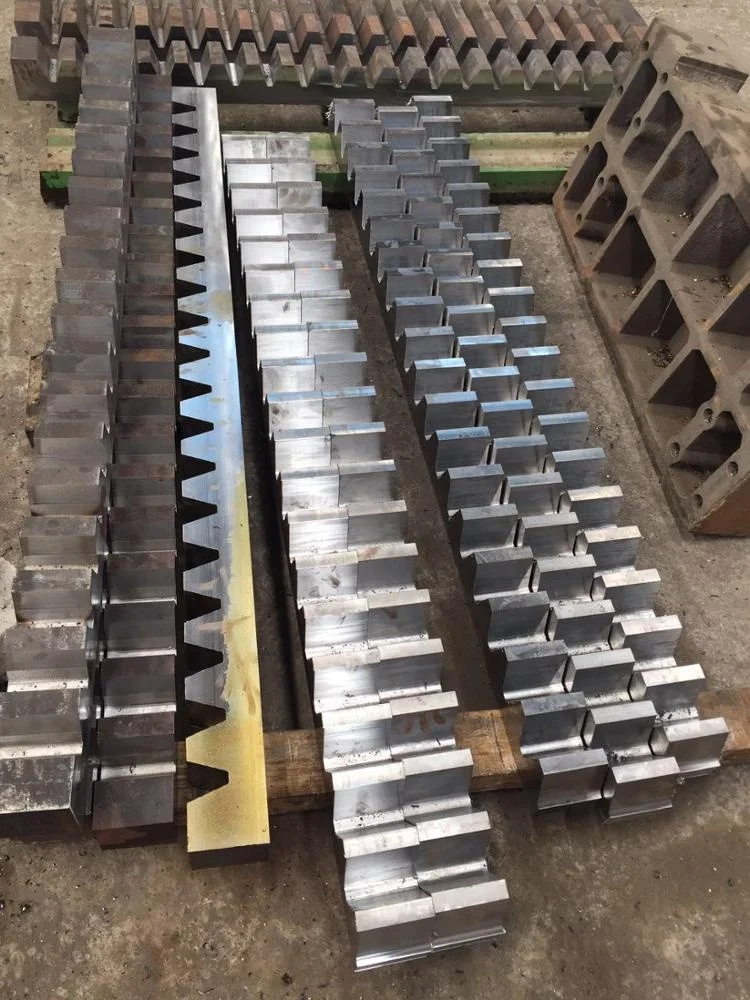

1. large module large size,Single rack maximum processing size is up to 10 meters.

2. high-precision, can be divided & stitching.

Application of spur helical precision rack and pinion

Gear racks are mainly used in Engineering transport machinery, ports, mines transport ,automatic loading and unloading truss robots, stacking robots, material handling devices, lifts. etc.

Gear rack is forged by a large-scale pneumatic hammer, the internal structure is dense, and Flaw detection for internal cracks.

CNC gantry milling machine would be leaved 3-5mm allowance according to different materials.

Heat treatment spur helical precision rack and pinion to increase the hardness and strength of the workpiece.

Prevent deformation of large size spur helical precision rack and pinion and prepare for further finishing.

Using Large-size CNC gantry milling machine, Accuracy is up to 0.01mm.

High-frequency quenching of the tooth surface is used to increases hardness and wear resistance.

Splicing and splitting to ensure product quality and ensure installation smoothly spur helical precision rack and pinion.

Standard export Packaging, Inner Wrap, then Plywood case.

YOGIE is mainly engaged in the designing and manufacturing of large machinery components and non-standard machinery parts according to customer's request, including shafts, gears, sprockets, mining machinery parts, weldings, bearings, castings and forgings etc.

The products are mainly used in the fields of mining, petroleum, cement, steel mill, power plant, sugar factory etc.

1. What is your terms of delivery?

A: FOB, CFR, CIF.

2. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

3. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Похожие товары

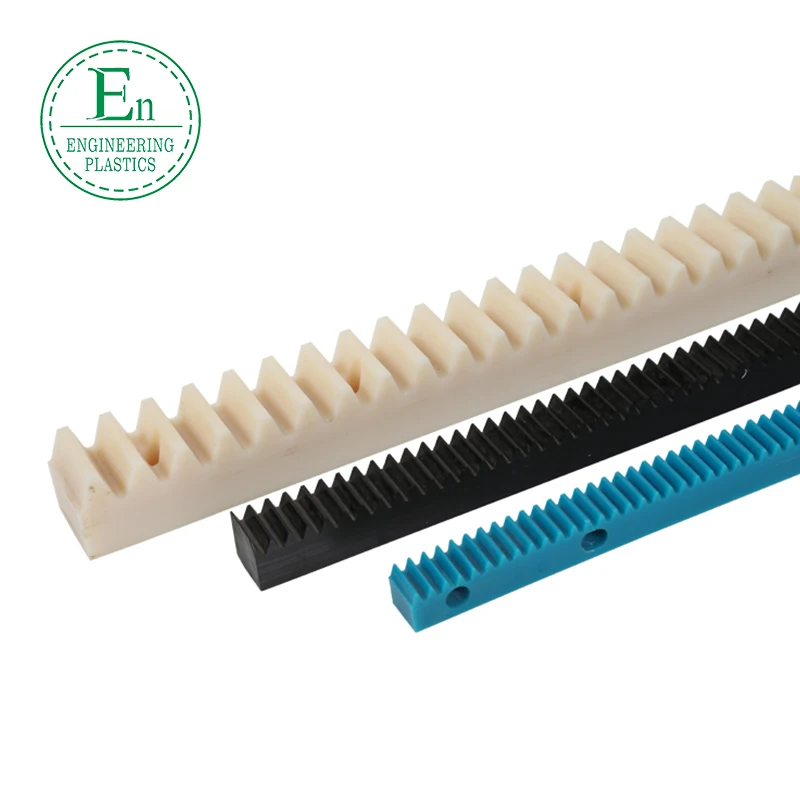

Пластиковые формованные гибкие

Диапазон 8 мм зубчатая рейка для контрольного замка автоматической раздвижной двери оцинкованный стальной стеллаж выставки товаров высокое качество низкая

Оборудование для ворот система раздвижных стойка с ЧПУ зубчатая шестерня раздвижной двери индивидуальная

Оптовая продажа шестерни и стеллажи для автоматических раздвижных ворот стальная шестерня

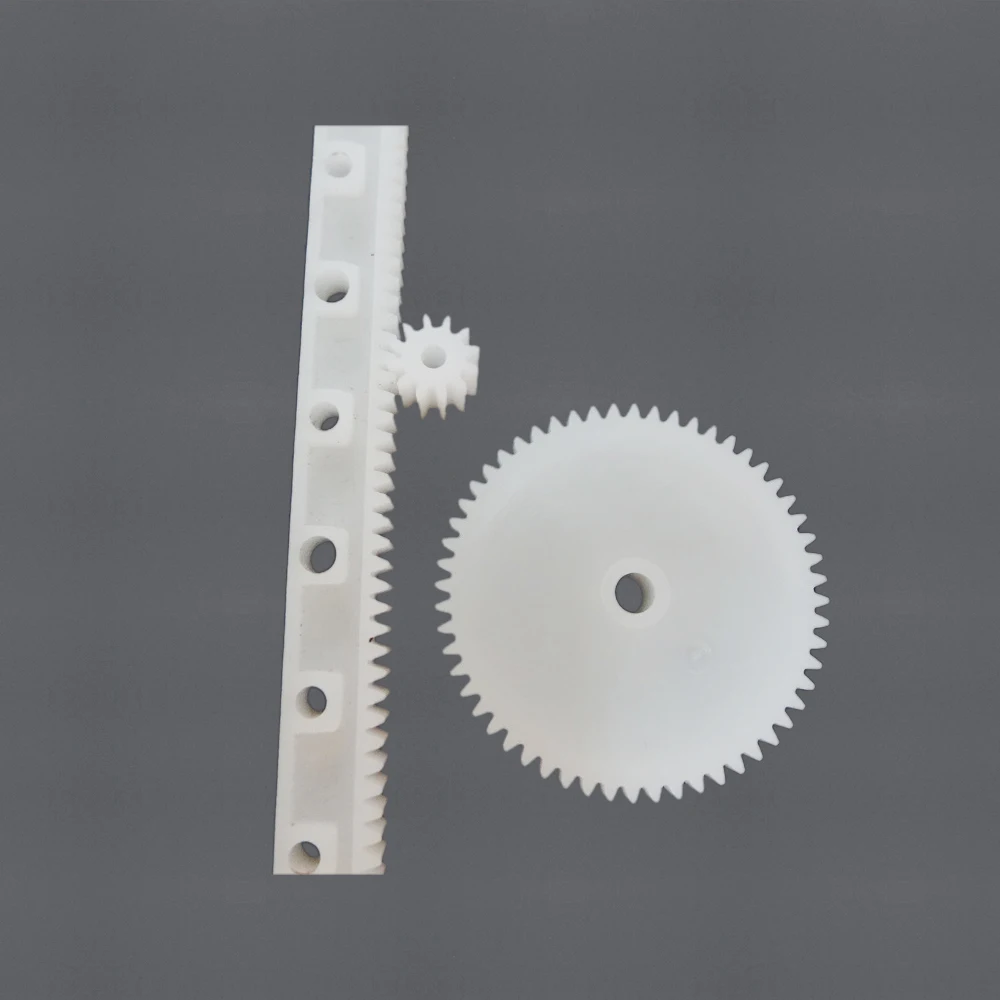

Точные детали для точной обработки с ЧПУ, нейлоновая стойка nylatron и шестерни

Пластиковый производитель PA6, нейлоновые пластиковые зубчатые шестерни

Пластиковая шестерня

Новые поступления

Новинки товаров от производителей по оптовым ценам