Немецкая технология шлифовки Raymond Mill

- Категория: >>>

- Поставщик: Henan Hongxing Mining Machinery Co. Ltd.

Сохранить в закладки 60841794952:

Описание и отзывы

Характеристики

Raymond Mill

Raymond mill is applicable to the grinding and processing of more than 280 kinds of non-flammable and non-explosive materials with hardness less than 7 and humidity less than 6% in mining, construction, chemical industry and metallurgy, such as stone flour, barite, bentonite, calcium carbonate, clinker, coal, dolomite, lead xide, limestone, marble, quartz, ultrafine.

The fineness of the finished product can be adjusted from 100 meshes to 325 meshes according to requirements. Raymond mill is the main and widely used grinding machine.

1. The whole grinding plant is a vertical structure of systematic characteristic, so it occupies small area. It is an independent production system from crushing of raw material to grinding and packing.

2. Compared with other grinding plants, its passing ratio achieves 99%, which is what other mills cannot reach.

3. Driving system of main frame adopts airtight gearing and pulley, drives smoothly and operates reliably.

4. Main parts of the Raymond grinding mill are made from cast and steel of high quality. The techniques are so subtle that they insure the durability of the whole plant.

5. The electric control system is integratedly controlled, so the automaticity is high. No people are needed in the operating room.

Compared with ball mill, this equipment has high grinding efficiency, low electricity consumption and small coverage size and one-time investment. The grinding roll tightly presses on the grinding ring under centrifugal force; for this reason, when the grinding roll and the grinding ring are abraded, the output and the fineness of the final products are not influenced. The changing cycle of the grinding roll and the grinding ring is long. The air separation flow of this machine cyclically flows inside the air blower, mill case, cyclone separator and air blower, so that compared with high-speed centrifugal crusher, this machine has little powder dust and the operational workshop is clean.

When Raymond mill works, the materials that need to be crushed are fed into the machine through the feeding hopper. The grinding roll that hangs on the main engine will rotate around the vertical axis and rotates around itself. Due to the centrifugal force produced in the rotating process, the grinding roll will swings outward and tightly press onto the grinding ring to make the relieving tool scoop up the materials and send them to the space between the grinding roll and the grinding ring, and the materials will be crushed due to the rolling and grinding of the grinding roll.

JAW CRUSHER

Ball Mill

Cone Crusher

Похожие товары

100% Высококачественное масло семян ятрофы/необработанное масло ятрофы/рафинированное масло ятрофы на продажу 2023

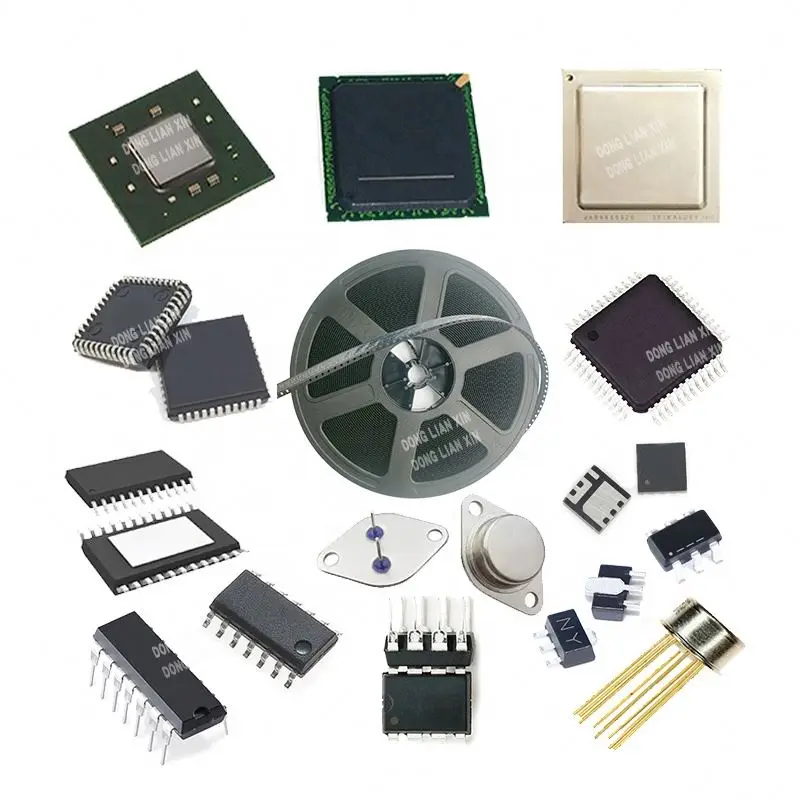

Новый оригинальный LIS3DETR LIS3DE 3DE LGA16 датчик ускорения интегрированный IC чип

Лидер продаж клей для нахлыстов ловушка насекомых одноразовая клеевая доска ловли

Новые синие 49cc 50cc мини-платье для детей кружевное мото 2 тактный полностью автоматический китайский питбайк детский Байк крест мотоцикл T01 в Китае (стандарты CE,

Стоматологический амальгам плуггер, пластиковые инструменты для наполнения, набор из 4 штук, двухсторонние ручные инструменты с индивидуальным цветом

Современная кожаная задняя деревянная рама, одно сиденье, мебель для кафе, угловой диван, сиденье, ресторан, стенд

Бледно-белый гранулированных твердых dcpd смолы нефтяных углеводородов смолы для

Новые поступления

Новинки товаров от производителей по оптовым ценам