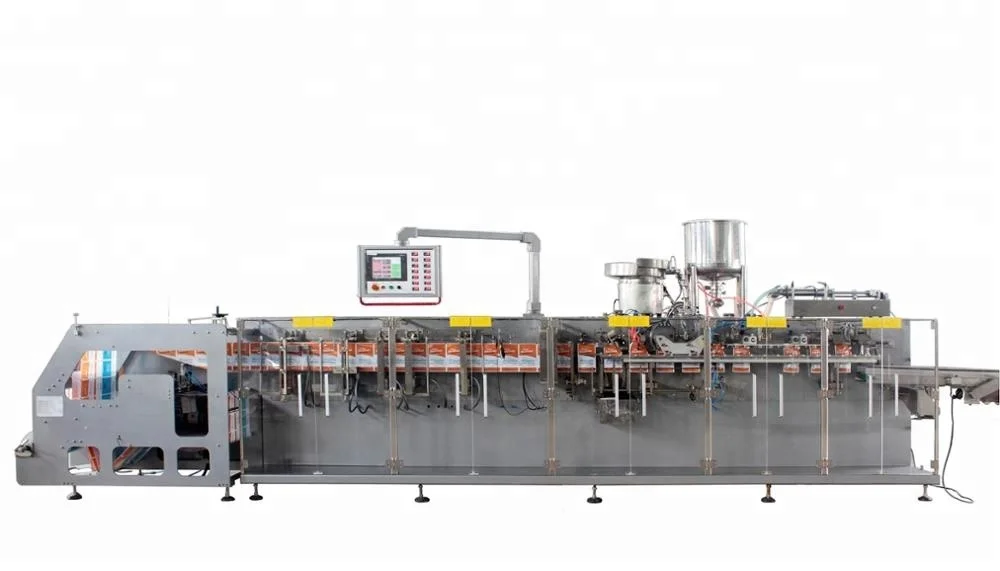

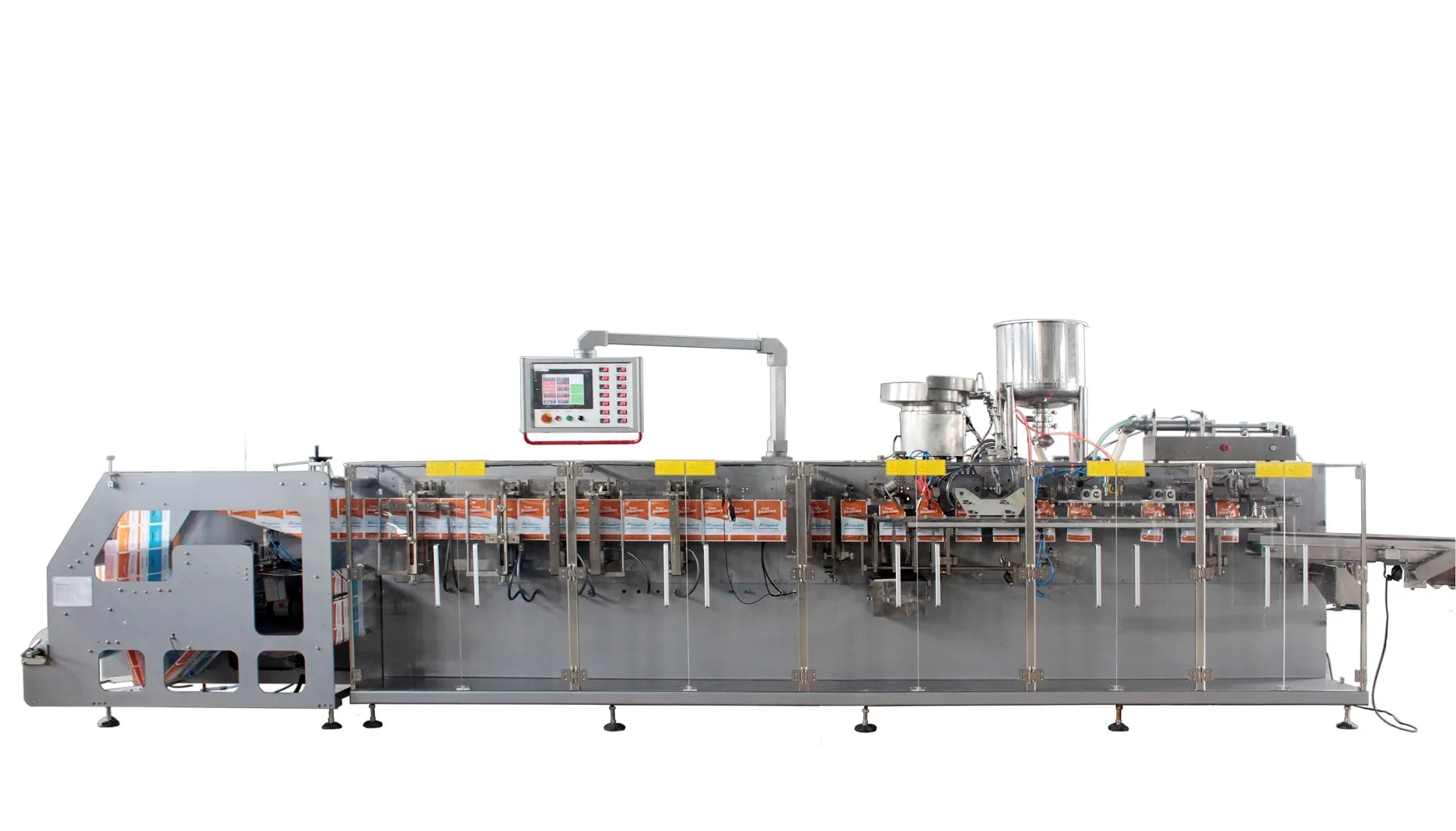

Горизонтальная автоматическая упаковочная машина HFFS с прямым угловым носиком

- Категория: >>>

- Поставщик: Wuhan Global Exchange Import And Export Limited

Сохранить в закладки 60844998428:

Описание и отзывы

Характеристики

Automatic Straight / Corner Spout Pouch Packing Machine

Application

This machine is applicable for packing powder, granule, liquid in form of corner spout pouch, with different patterns of sealing, which include processes of flat pouch or stand up pouch forming, product dosing, filling, corner spout installation and sealing.

Application Description | |

Applicable Pouch | Corner spout flat pouches, corner spout stand up pouches, or other irregular shaped corner spout pouches. |

Applicable Products | Configure with different dosing devices, capable to pack with liquid, powder or granule, such as juice, jam, ketchup, mayonnaise, baby puree, engine oil, motor oil, detergent etc. |

Material | Laminate Heat sealable packing materials such as OPP/PE, BOPP/OPP/PE, PET/AL /CPP etc. |

Working Processes

Film Unwinding Process

Note: the gusset hole punching process applies for stand-up pouch

Pouch Forming Process

Pouch Filling Sealing Process

Note:

1) The product filling process can be 1 to 4 station according to project requirement

Features

Standard Features

1) Stand up pouch form fill, corner spout installation and seal

2) Rigid carbon steel structure with plastic spraying process and covered by stainless steel 304

3) Anodic oxidation and/or harden aluminum for main movement beam and pouch holding bars

4) Stainless steel 304 for product touching parts

5) PLC & Touch Screen HMI Control

6) Intelligent PID temperature controller

7) Servo motor for film pre-pulling and bottom hole punching

8) Easy pouch length adjustment

9) Twice product filling, twice vertical sealing and twice horizontal sealing processes

10) Once pre-heating, three times pressurized heat sealing, once cold sealing, used for corner spout installing and sealing

11) Pouch vacuum and mechanical opening

12) Vacuum system powered by vacuum pump with negative pressure tank

13) Individual pressure tank for different compress air supplies

14) Pouch not open completely, no fill and seal interlock

15) Central lubrication system for punching device and other key mechanical parts

16) Visual Protective Cover

17) Cold Embossing type coding

Optional Features

1) Flat top spout pouch

2) Irregular shaped top spout pouch

3) Stainless steel 316 for product touching parts

4) Automatic film offset correction system

5) Ribbon, inkjet or laser coding

6) Cold sealing with chiller

7) AB Control System

Advantages

Techniacl Specification

HMS-1600XC | HMS-3200XC | |

Packaging Speed | 35-45 pouches/min | 35-45 pouches/min |

Lanes | 1 Pouch/cycle | 1 Pouches/cycle |

Vertical Sealing Station | 2 | 2 |

Pouch Size-Length | 100-270 mm | 100-400 mm |

Pouch Size-Width | 80-160 mm | 80-250 mm |

Film Pulling Driven | Servo Motor | Servo Motor |

Power Consumption | 12 kw | 13 kw |

Power Requirement | AC 380V 50/60HZ | AC 380V 50/60HZ |

Type 1G-xxxx | HMS-1600DXC | HMS-3200DXC |

Packaging Speed | 60-80 pouches/min | 60-80 pouches/min |

Lanes | 2 Pouches/cycle | 2 Pouches/cycle |

Vertical Sealing Station | 2 | 2 |

Pouch Size-Length | 100-270 mm | 100-280 mm |

Pouch Size-Width | 80 mm | 80-130 mm |

Film Pulling Driven | Servo Motor | Servo Motor |

Power Consumption | 13 kw | 14 kw |

Power Requirement | AC 380V 50/60HZ | AC 380V 50/60HZ |

Item | Making Bags | Applicable pouches | Size of bag (mm) | Reference Filling Range (g/bag) | Packaging Speed (bags/min) |

PP146 | No | Premade stand up pouch top straight spout installation | W: 60-180 L: 80-260 | ≤600ml | 30-60 |

Premade pouch corner punching corner spout installation | W: 100-180 L: 120-250 | ≤600ml | 25-35 | ||

Premade stand up pouch top straight spout installation | W: 90-180 L: 110-260 | ≤1000ml | 60-90 | ||

PP133 | No | Spout pouch

| Filling Heads: 5 Capping Heads: 5 | 100-500ml | 50-80 |

Filling Heads: 8 Capping Heads: 4 | 1000-3000ml | 30-45 | |||

PP120 | Yes | Top straight spout stand up pouch | Packaging Film Width: 150-330 | 50-500ml | 10-25 |

Packaging Film Width: 400-650 | 200-1000ml | 10-25 | |||

PP217 | Yes | Top straight spout stand up pouch | W: 90-180 L: 110-260 |

| 40-60 |

Corner spout stand up pouch | W: 110-180 L: 180-260 |

| 40-60 | ||

Corner spout stand up pouch | W: 110-240 L: 180-320 |

| 40-60 |

PP146 PP133 PP120

Похожие товары

40L промышленная Автоматическая чаша измельчитель машина для переработки мяса цена

Золотой поставщик mingxin power 12v2a 24 Вт 12V3A 36 Вт Мобильный HDD ac/dc источник питания

KG-1001 новый и высококачественный импульсный поставщик электропитания с завода zhaoxin с CE

Бесплатный образец! Магнитный контактор LC1 D115A CJX2 -D115, контактор переменного тока 380 В с сертификацией CE

Китайский поставщик портативных мобильных устройств для устройств apple android

Беспроводная зарядка Мобильная мощность 10000 мАч от поставщика мобильных устройств Шэньчжэнь

China Supplier Bank Station Generator Outdoor Camping Portable Power

Новые поступления

Новинки товаров от производителей по оптовым ценам