Простота в эксплуатации продукта DH A2E низкая цена bga паяльная станция индии для ремонта ноутбука мобильный блок печатных

- Категория: >>>

- Поставщик: Shenzhen Dinghua Kechuang Technology Co. Ltd.

Сохранить в закладки 60875692847:

Описание и отзывы

Характеристики

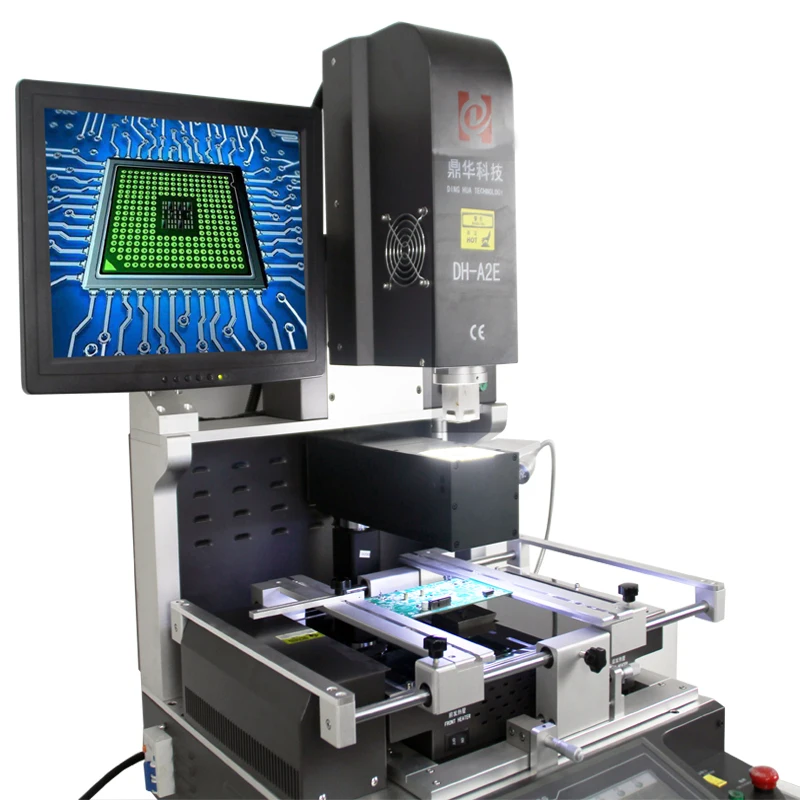

Below is the Advantages of DH-A2E BGA REWORK STATION

BGA Rework Station Motherboard Rework Station for TV/laptop/PS3/Xbox360/Cell phone

Features Summary

﹡ Widely used in Chip Level Repairing in laptop, PS3, PS4, XBOX360, Moblie Phone, Computer, TV, control boards etc.

﹡ Rework BGA, CCGA, QFN, CSP, LGA, SMD, LED etc.

﹡ Automatic desoldering, Mounting and Soldering, automatic pick up chip when desoldering completed.

﹡ HD CCD Optical Alignment system for precisely mounting BGA and Components.

﹡ BGA mounting accuracy within 0.01mm , Repair success rate 99.9%.

﹡ Laser Positioning for Fast Positioning BGA Chip and motherboard.

﹡ Superior Safety Functions, with Emergency protection.

﹡ User-friendly operation, Multi-functional ergonomic system.

Specifications | ||||||

1 | Total power | 5300w | ||||

2 | 3 independent heaters | Top hot air 1200w, lower hot air 1200w, bottom infrared preheating 2700w | ||||

3 | Voltage | AC220V±10% 50/60Hz | ||||

4 | Electric parts | 7’’ touch screen + high precision intelligent temp control module + stepper motor driver + PLC + LCD display + high resolution optical CCD system + laser positioning | ||||

5 | Temperature control | K-Sensor closed-loop + PID automatic temp compensation + temp module, temp accuracy within ±2℃. | ||||

6 | PCB positioning | V-groove + universal fixture + movable PCB shelf | ||||

7 | Applicable PCB size | Max 370x410mm Min 22x22mm | ||||

8 | Applicable BGA size | 1*1mm~80x80mm | ||||

9 | Dimensions | 600x700x850mm (L*W*H) | ||||

10 | Net weight | 70 Kg | ||||

Product Features

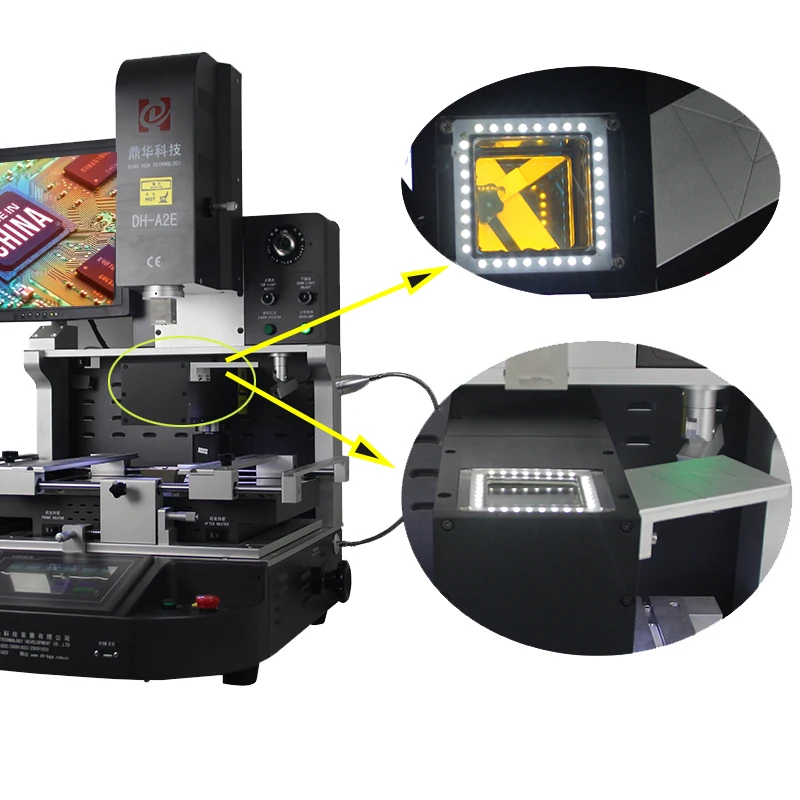

◆ Precise optical alignment system

① Color optical system with functions of split vision, two color separation, zoom in/out and micro-adjust, equipped with aberration detection device, with auto focus and software operation

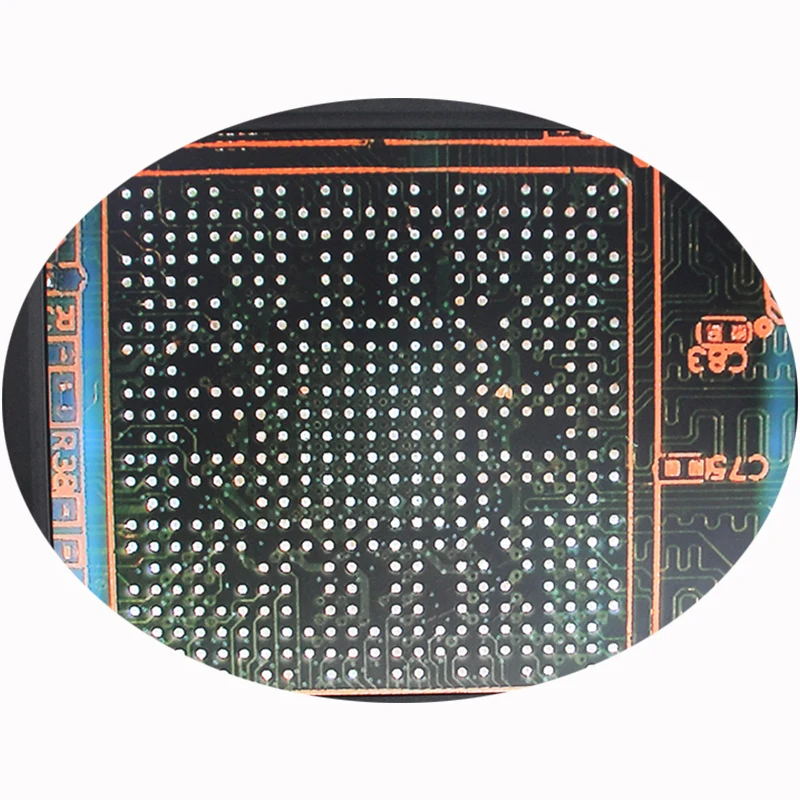

② CCD camera amplify up to 200x, with top/down light brightness adjust function, mounting accuracy is within 0.01 mm

◆ Advanced features

① Top hot air flow is adjustable, to meet the demand of any chips.

② Desoldering, mounting and soldering automatically. Auto feeding system enabled.

③ Built-in infrared laser positioning, help fast positioning for PCB.

④ Top heating head and mounting head 2 in 1 design.

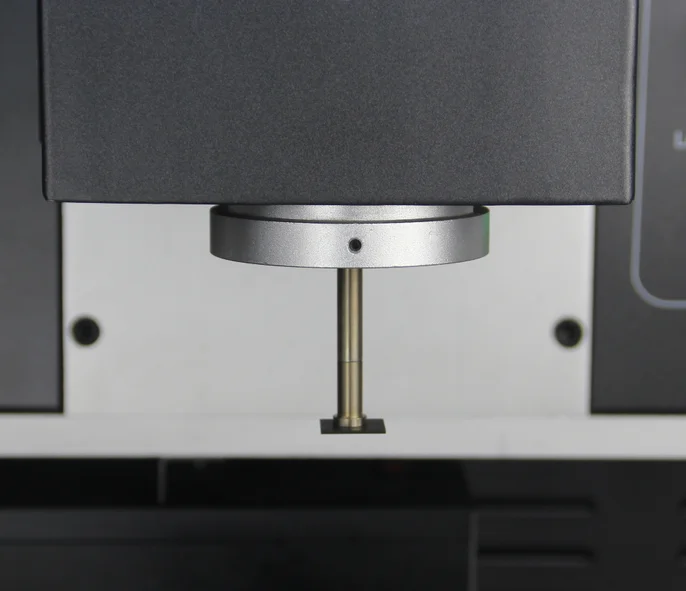

⑤ Mounting head with built-in pressure testing device, to protect the PCB from being crushed.

⑥ build-in vacuum in mounting head pick up BGA chip automatically after desoldering completed.

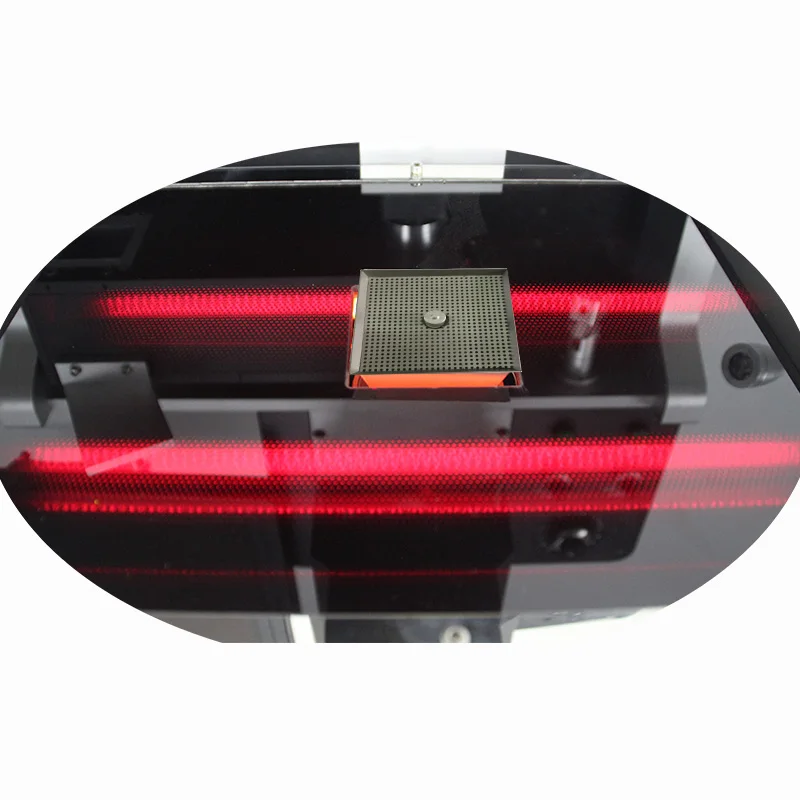

◆ Three independently controlled heaters

① top and bottom heaters are hot-air heating, the third is infrared preheating zone, the top and bottom heaters can set 8 segments rising temperature/constant time/temperature rising slope , can save tens of thousands of groups temperature curves.

② it can heat PCB board and bga chips at the same time. And the third IR heater can preheat the PCB board from bottom evenly, to avoid PCB from deformation during repair process. All three heaters can heat independently .

③ It uses k-type thermocouple closed-loop control and PID automatic temperature compensation system, together with PLC and temperature module to enable precise temperature deviation to ±2 degree centigrade.

④ The external sensor can detect temperature precisely, analyze and calibrate the real temperature curve accurately at any time.

◆ Multi-functional ergonomic system

① bottom heater can be adjusted up and down.

② Adopted all kinds of magnetic top and bottom nozzles, with 360° rotation, easy for installation and replacement, customized sizes are available.

③ Multi-functional PCB support shelf, can be moved along X axis, together with universal fixture and V-groove bracket, suitable for all kind of PCB positioning.

④ powerful cross-flow fan automatically cool the PCB board fast after desoldering or soldering completed, it can prevent the heaters from aging. Fan will be shut down automatically when the heaters temperature drops to normal temperature.

◆ Superior safety functions

Machines are CE certification guaranteed. It is equipped with emergency button. Also there is voice warning around 5 seconds before soldering/desoldering process complete. With automatic power-off protection device when abnormal accident happens, with a double over-heating protection control.

High resolution optical CCD Alignment system for precisely mounting BGA and Components. Mounting accuracy is within 0.01mm

Built-in infrared laser positioning, help fast positioning for PCB board.

Auto feeding system enabled.

Desoldering: mounting head auto pick up bga chip and place it on the feeding plate.

Soldering: mounting head auto pick up bga chip from feeding plate.

Packaging | ||

Size | 820 (L) * 870(W) * 870(D) mm | |

G.W. | 117 Kg | |

Packaging Details | Packed carefully, protect the machine well. | |

Delivery | ||

◆ Sample woulde be sent within 5 business days after receiving full payment. 7-15 days for bulk order. ◆ Shipping By DHL, FedEx, TNT, EMS, UPS express. You can also choose sea shipment. | ||

Below is the six reason why MOST CLIENTS prefer to choose DINGHUA BGA REWORK STATION

Some pictures of our factory and BGA rework station manufacturing lines

Part of our Clients

Part of our Certifications

The most professional technician:

After he watched our sales'operation and introduction at booth, the professor from University of the Americas has been impressed and decided to pay a visit to our factory & get more details about us.

He bought 3 sets of DH-A4D for his Lab at last.

Powerful distributor in Middle-East

On the basis of trusts after several times cooperation, the customers visited our factory & decided to purchase 200 sets of BGA rework station one time, in order to expand their business in the coming future.

Favorable Comments for our service

Those customers who bought our machines left wonderful comment and thanks for the service we offered, sustain persuit for excellence to the quality, and kindness care we co-operate with them.

I belive there's no such a good partner like us.

Q: Are you trading company or manufacturer ?

A: We are factory, and it is the biggest workshop in this industry in China, also have our own R&D.

Q: How long is your delivery time?

A: Generally it is 2~3 days if the goods are in stock. or it is 5~20 days if the goods are not in stock, it is according to quantity.

Q: How to use a BGA rework station?

A: There is teaching CD, also, we can help you by video talking on skype, Wechat, WhatsApp,Messemger and viber etc.

Q: What is your terms of payment ?

A: Payment<=1000USD, Paypal optional, 100% in advance.

Payment>=5000USD, trade assurance(one of ways on Alibaba paid, and buyer shopping rights can be protected)

Payment>=10000USD, 30% T/T in advance ,balance before shippment.

Q: How to choose a BGA rework station?

Похожие товары

Подшипник бесплатный образец китайского производства шарикоподшипник с глубоким желобом открытые шарики подшипника 2RS ZZ 6001 6008 6010

Шариковый подшипник с глубоким желобом из хромистой стали OEM

Хорошая цена, размеры подшипников 6010 2RS, радиальный шарикоподшипник, высокоскоростные небольшие шарикоподшипники

6010 110 размер 50*80*16 конический роликовый подшипник хромистой стали шариковый подшипник с глубоким жёлобом, высокое качество и низкая цена с фабрики напрямую

6010 Сделано в Китае, все типы шариковых подшипников с глубоким желобом, оригинальный KOYO NSK NTN 6010, подшипники, готовые к отправке

Подшипник 6010-Z/Z3/2RS/C3/P6 глубокий шаровой подшипник 50*80*16 мм китайский поставщик

Из pom-пластика подшипник 6000 6001 6002 6003 6004 6005 6006 6007 6008 6009 6010 изоляции и водонепроницаемый могут быть выполнены по индивидуальному заказу

Новые поступления

Новинки товаров от производителей по оптовым ценам