Плавная работа экспортируется в ОАЭ машина для формовки металлочерепицы крыши

- Категория: >>>

- Поставщик: AMECO INDUSTRIAL JOINT STOCK COMPANY

Сохранить в закладки 62000053592:

Описание и отзывы

Характеристики

Product Application

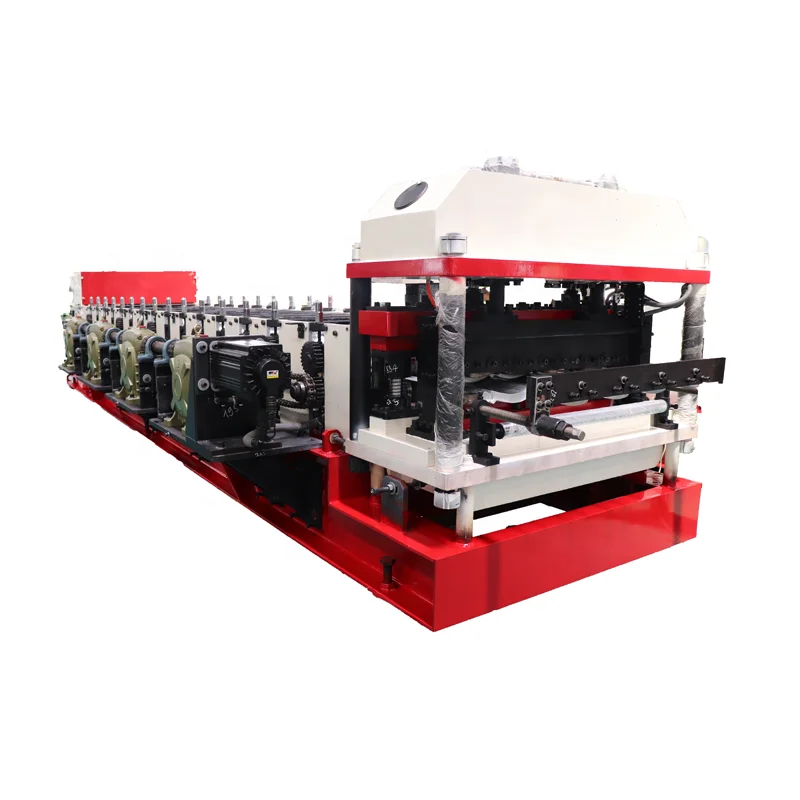

Tile Roofing Roll Forming Machine is able to roll form hardest materials with minimum thickness 0.2 mm. Ameco has three models for Metal Step Tile Roll Forming Machine: Economy, Standard, and Advance.

Regular: Machine with speed driven by proportional valves. (3–3.5 m/min)

High-speed: Machine with speed driven by Inverter and unique hydraulic system. (5–5.5 m/min)

Super-high-speed: Machine with speed driven by Inverter and double hydraulic system. All Rollers are made of high-quality material and gone under Taiwan vacuum heat treatment which makes them stronger. (7–8 m/min)

| \t | |||

| \t | \t | \t | \t |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | \t |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | \t |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | |

| \t | \t | \t | |

Main Features

1) Easy in installation and maintenance.

2) Hardened structural steel and components provide long life and safe operational stability.

3) Adopting advanced world famous brand components in controlling parts, electric parts and operation parts.

4) Running in an automation, high durability and stability.

5) Compact design, meet custom demands.

Machine Parts

Name: Roller

Ameco Rollers are custom designed and machined precisely by state-of-the-art CNC machines placed inside the factory.

Rollers are hardened through vacuum heat treatment (Taiwan technology) and chrome plating.

Main Features

Name: Frame

Frame are made by hardened steel and connected by bolts which make machinery sturdy, easy to maintain, and avoid deformation while operating.

Machine Parts

Name: Cutting and Pressing

Shearing (Cutting) die set and Punching die set are separated, made by S50C or SKD, gone through vacuum heat treatment to have a longer lifespan.

Main Features

Name: Control System

Control system with intelligent PLC and HMI touch-screen helps to operate machine simply and to create identical rollformed steel sheets which present your exact specifications.

Ameco Vietnam has applied high technology in machinery such as modern Inverter and Servo to increase speed, operate smoothly, and save energy.

| \t | |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | |

| \t | \t |

| \t | \t |

| \t | \t |

Market Scale

Ameco has exported to over 50 countries in 5 continents.

Since 2000

Ameco team has designed and manufactured metal forming machine for 19-20 years.

Quality Management system

Quality Spare-parts Tooling, reputable imported Brands Equipment

Spare-parts are released under strict revision control.

Green, Eco-friendly Machinery

Using state-of-the-art technology such as Servo, Inverter to save energy, lessen noise, optimize machine longevity.

After-Sales guarantee

High responsibility in our product. Contact us, we'll contact to solve your issue within 1-3 days.

Pre-Sales Service

* Inquiry and consulting support.

* Factory visit Service: Ameco will take care of your trip from Tan Son Nhat airport/your hotel to the factory.

After-Sales Service

* Installing and Training how to operate machine.

* Engineers available to service machinery overseas.

1. Do you do custom roll forming machinery or custom coil processing equipment?

Yes, we do. We specialize in designing and manufacturing custom machine. Just providing us your desired profiles and requirements such as component brand, type of material, we can make machines that fit your needs.

2. How fast is your machine?

Speed depends on machine's type: up to 9 m/min for Metal Tile Roofing Roll Forming Machine; up to 55-60 m/min (super high speed) for Trapezoidal/IBR Roofing Roll Forming Machine.

3. What material thicknesses can be formed? Can your machine process full hard material?

Material Strength: G300 – G550.

4. Can you ship internationally?Do you offer on-site visits?

Yes, we visit your site for installation, training, repairing and other purposes as required.

5. Warranty? Repair Service Arrangement?

6. For how long my machine will be checked/ repaired?

We will arrange technician(s) to support you online (with simple cases) or come to your factory to fix them. Maximum is two days from notification date; our technicians will start taking care of your machines.

Metal Tile Roofing Roll Forming Machine

91.8% Response Rate

Advance Crimp Curving Machine

91.8% Response Rate

Advance Roofing Roll Forming Machine

91.8% Response Rate

Похожие товары

Новая автоматическая машина для резки листовой стали 380 В

Двойная линия гипсокартон Гипсокартон Профиль Металл Профилегибочный станок для изготовления стоечных и направляющих профилей

Металлический кровельный лист гофрирующий железный машина для формовки холодная оцинкованная линия

Производственная линия для формования рулона цветная стальная крыша и настенная плитка делая машину

Лидер продаж многофункциональная машина для формирования плитки терраццо отличная производительность распродажа

Машина для изготовления листов кровельной плитки машина гофрирования и трапециевидной двухслойная металлическая сталь

Машина для изготовления бетонной кровельной черепицы машина гофрированного цемента

Новые поступления

Новинки товаров от производителей по оптовым ценам