1220 мм ПВХ мраморная машина для экструзии листов

- Категория: Plastic Extruders >>>

- Поставщик: Shenzhen HYPET Co. Ltd.

Сохранить в закладки 62003516277:

Описание и отзывы

Характеристики

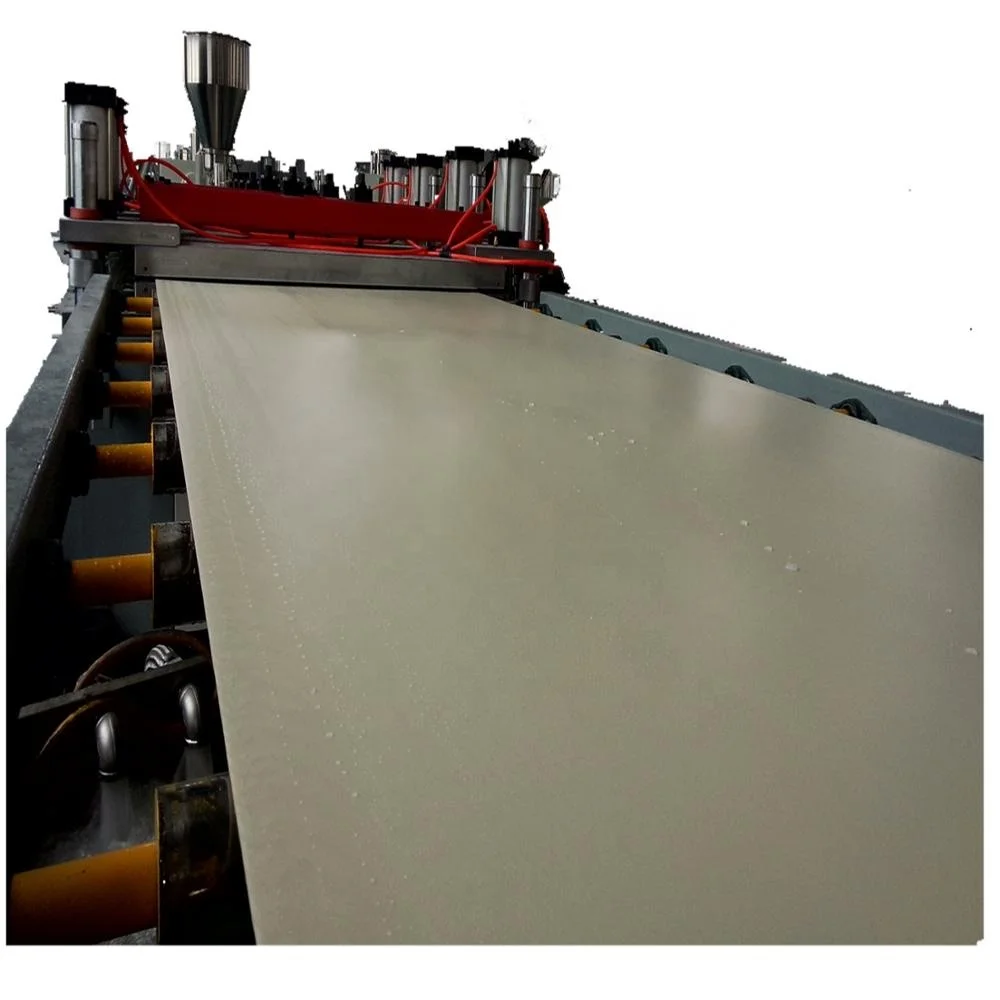

1220mm PVC marble sheet extrusion machine

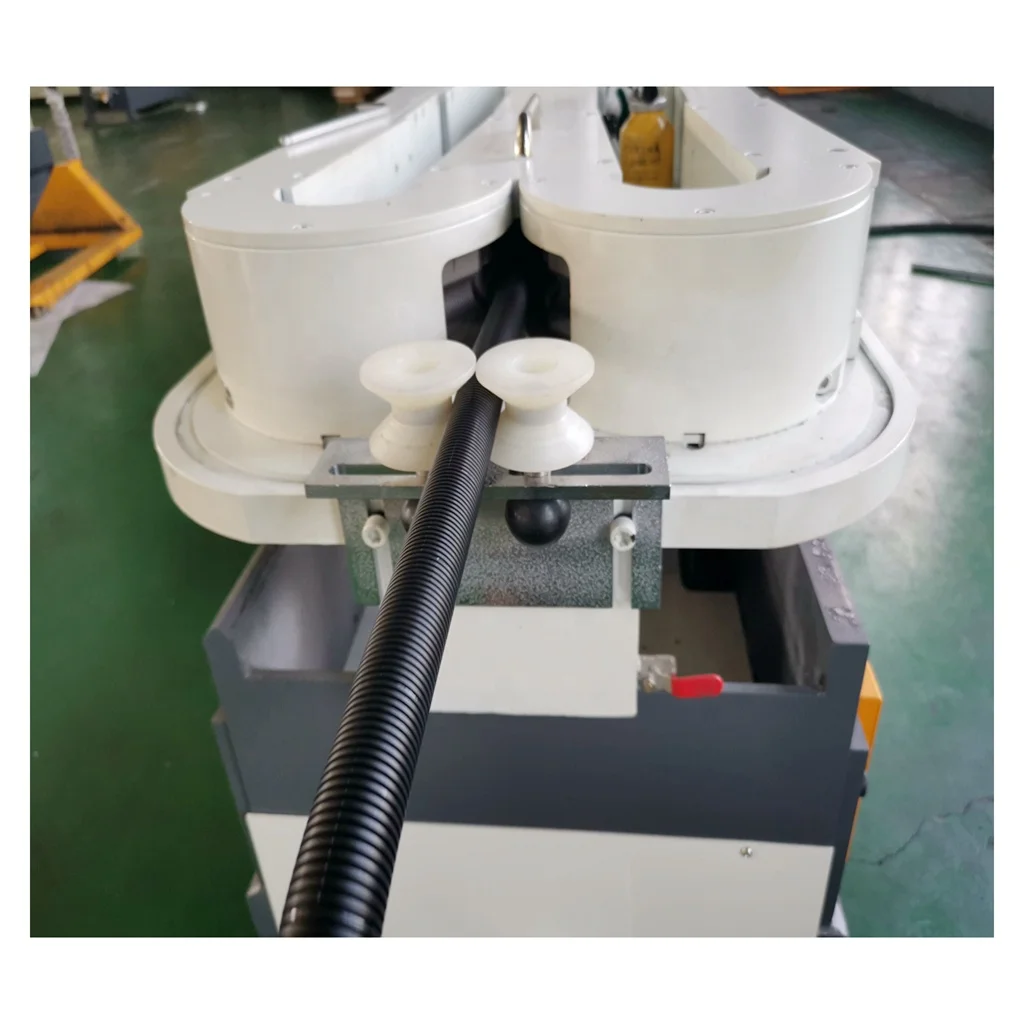

1. This production line consists of special twin screw extruder, mould, vertical installed 3-roller calendar, and auxiliary machines, our company will offer formulation and full sets of technology of the complete processes. The production line has the advantages of large output, stable extrusion, and high foamed ratio.

2. The barrel and screws of extruder are specially designed for PVC and WPC foamed products extrusion, venting type design, the barrel and screws are bimetallic treatment, effectively reduce the big wearing problem caused by PVC and WPC materials, highly increases the service life of extruder.

3. Adopting PLC people-machine interface computer control,Siemens LCD. The operation parameters can be customized and showed on the display.

4. Material of mould is high quality alloy steel 5CrNiMo forging treatment, the surface of inner flow channel is under chrome plating treatment and polish treatment. The structure of mould adopts imported technology, the die cavity under hard chrome plating treatment and mirror type polishing treatment.

Selection of raw materials for PVC free foam board production

PVC resin is a strong polar polymer, and its intermolecular force is relatively large, resulting in high softening and melting temperature. Generally, it needs to be processed at a temperature of 160~210 °C. In addition, PVC is extremely unstable to heat, and the temperature rise will greatly promote the de-HCL reaction of PVC. Pure PVC starts to de-HCL reaction at 120 °C, which leads to PVC degradation. In view of the above two defects, PVC needs to add additives in the processing to ensure that it can be plasticized, foamed and molded at the processing temperature to produce qualified products. When selecting the type and amount of additives, various factors must be considered, such as physical-chemical properties, flow properties, molding properties, environmental sanitation performance, etc., and finally the ideal formulation is established. In addition, depending on the product and equipment, the choice of resin type also needs to be made. The combination of different types of PVC resin and various additives is the PVC formula design we often say. PVC free foaming board generally needs to carry out subsequent processes such as printing, laminating and engraving to meet different requirements. Therefore, the thickness deviation and surface quality requirements of the sheet are very strict. During the processing, there is high pressure gas in the melt. The melt flow is not the same as the general melt. Therefore, there are many unique features in the formulation design, and the selection of various raw materials is also high. Formulation design includes resin selection, stabilization system, modification system and selection of lubrication system and determination of ratio

A) PVC resin

PVC free foaming board formula generally does not add plasticizer, resin plasticization performance is critical, plasticization is the premise of foaming and molding; uncut sheet width can be up to 1.3 meters, very good for melt flow High, so the choice of resin is especially important. As the degree of polymerization of PVC increases, the intermolecular van der Waals force or the degree of entanglement increases accordingly. The better the stiffness, strength and toughness of the product, the better the heat resistance, low temperature resistance, aging resistance and light resistance, but the higher the degree of polymerization, the plastic The more difficult it is, the higher the processing temperature and the worse the fluidity.

B) Heat stabilizers

A heat stabilizer is a substance that is capable of removing unstable chlorine groups, absorbing hydrogen chloride, and terminating the growth of the polyolefin series. In addition to ensuring the normal extrusion of the material during the processing, the stabilizer also imparts a certain light, weather and heat resistance to the finished product. The heat stabilizer contains active metal ions, which can lower the decomposition temperature of the foaming agent, so that the foaming agent can be completely decomposed at the processing temperature to generate a gas and form a bubble-containing melt. Composite stabilizers generally have certain lubricating properties

C) Lubricant

In order to improve the fluidity of the PVC melt and prevent the molten mixture from adhering to the processing equipment, a lubricant (6) is added. In PVC processing, during the melting and conveying process, due to the shearing force, friction occurs between the PVC molecules and between the PVC and the processing equipment.

D) Processing aids

PVC melt is poor in ductility, easily leads to melt damage, and it is slow to relax, easily causing surface defects, dullness or shark skin. Processing aids are generally considered to be a class of polymer additives that improve the melt processing properties of PVC resins when added in small amounts.Processing aids used in free foaming board formulations, sub-foaming regulators and lubricated processing aids

1, foaming regulator

Foaming regulator is a special processing aid. It is an ultra-high molecular weight polymer. Due to the low degree of polymerization of the PVC resin used, the melt strength is not high. If no foaming regulator is added, the melt may not be sealed. When gas is lived, melt fracture occurs, and large bubbles are generated, resulting in uneven cells, which affect product quality.

2. Lubricating processing aid

Lubricating processing aid is a special PVC processing aid, which promotes gel and external lubrication function. It can promote plasticization during plasticization. For plasticized melt, it has metal stripping effect. Reduce friction with metal and extend boot time. Imported Rohm and Haas K-175, domestic Suzhou Amway ACR-301 are commonly used PVC free foaming board lubrication processing aids

E) Foaming agent

The most commonly used foaming agent for PVC free foaming board is AC foaming agent. “Because of the special mechanism of the extruder and the mold, the pressure inside the barrel and the mold is very high. The blowing agent separates the liberated gas and dissolves into the PVC melt under high pressure. When the melt is extruded into the mold, it is melted. The body suddenly loses pressure, and the gas dissolved in the melt rapidly expands and foams, and then the cooling is immediately set.

F) Filler (nucleating agent)

Active light calcium carbonate (referred to as active light calcium) is the most commonly used filler, which can improve the heat resistance of the product, reduce the cost, and also acts as a nucleating agent in the foaming process. Its fineness is a key factor affecting product performance. The filler can overcome the shortcomings of PVC plastics such as high temperature resistance, low rigidity, easy expansion, creepiness and dimensional instability.

G) Foaming agent zinc oxide

In the PVC free foaming board, a foaming aid is sometimes added to improve the foam structure and foam quality. The most commonly used foaming aid is zinc oxide, and the amount is generally 0-5 phr.

H) Titanium dioxide and UV absorbers

In order to improve the weather resistance of the sheet, it is necessary to add titanium dioxide and ultraviolet absorber. Titanium dioxide is divided into two types: rutile type and anatase type. For outdoor use, rutile type should be added, and anatase type can be added for indoor use. The UV absorber is generally UV-531 and may not be added indoors. Titanium dioxide is also a colorant that increases the brightness and whiteness of the board.

A.Formula and raw material description

| Type one | Type two | Type three |

| PVC(K=57) 100 | PVC(K=57) 100 | PVC(K=57) 100 |

| 10F 10 | 10F 8-10 | 10F 12—15 |

| 316A 0.3 | 316A 0.3—0.5 | 316A 0.8 |

| Calcium-zinc: 4—5 | H—3 2.5 | H—3 3 |

| G60 0.6—0.8 | ||

| OPE 0.4—0.5 | TS-181 1.5—2 | TS—181 1.5—2 |

| Density 0.4—0.5 | ||

| NH600 0.4—0.5 | NH-600 0.4—0.5 | NH600 0.8—1.2 |

Titanium pigment 5 | Titanium pigment 5 | Titanium pigment 5 |

| K175 1.5 | K175 1.5 | K-175 2 |

| Active light CaCO3 10 | Active light CaCO3 10 | Active light CaCO3 10 |

Main technical parameters of PVC free foam board production line

| Type | Width | Thickness | Extruder | Output | Motor |

| PVC free foam board | 1220 | 3-20 | HYZS80/156 | 350 | 75 |

| PVC free foam board | 1600 | 5-30 | HYZS92/188 | 500 | 110 |

| PVC free foam board by co-extrusion | 1600-2050 | 3-20 | HYZS80/156, HT65/132 | 600 | 120 |

1. We have more than 30 years in extrusion field

2. Introduction from German tech and experience for the design and making twin screw extruders. And leaded by Germany experts Mr. Youcef and Mr. Elben for the long time

3. Designed and produced twin conical screw extruder, twin parallel screw extruder, and transfer the technology to the biggest gears factory in India

4. With high professional design team

5. A base combined with designing, making, studying in extrusion industrial.

6. Our philosophy is to learn advanced technology, make the best suitable machine, best efficient machine and best lines.

1. In 2002 the company was established.

1. In 2002 the company was established.

2. In 2004, the establishment of plastic extrusion machinery Institute to study and study the German extrusion machinery technology.

3. In 2006, developed a continuous straight cone double reducer, for the Chinese machinery to jump on a step to contribute.

4. In 2007, developed a series of flat double reducer, the smallest 65, the largest 130, to fill the gaps in the domestic, while forming a high level of flat and cone series twin screw extruder, welcomed by the market warmly.

5. In 2008, the opening of its own 10,000 square meters of large-scale mechanical plant, as Huiyi large-scale production base.

6. In 2009, developed its own twin-screw split double alloy barrel, wear-resistant, long life, has been well received by customers, and some customers can even use 7 years.

7. In 2010, focusing on the development of Pakistan, India, Kenya, Algeria, Egypt, Saudi Arabia, Brazil, the United States, Portugal and other countries of the customer network.

8. In 2012 PE / PRR pipe unit R & D success, the most advanced and efficient single screw extruder, to achieve high yield, high efficiency, low energy consumption of the best results, screw barrel bimetallic, life than the general to extend 80%.

9. In 2013, flat double extruder on the steps, PS67 / 27 parallel twin extruder 30kW motor production reached 300 kg / h 90/27 to 500kg / h, PS107 / 27 extruder to 800kg / h.

10. In 2014, cone double extruder power unchanged, yield increased by 30%, ZS65 / 132 extruder production reached 350kg / h, ZS80 / 156 extruder production reached 550kg / h

11. In 2014 sales of flat double reducer technology to India.

12. In 2015, with foreign experts to develop suitable for plastic machinery energy-saving devices, energy saving up to 25-30%, is currently applying for technical patents.

13. In 2016, the development of a new technology 630PVC large tube unit, high output, stable and reliable production, to the advanced level.

Похожие товары

Линия по производству пенопласта 3 мм-40 мм из ПВХ и ДПК/машина для формования пластиковых деревянных Композитных плит/машина для производства ДПК

Высокоскоростной экструдер для производства гофрированных труб с одной стенкой и двойными стенками, машина для изготовления гофрированных труб DWC

Пластиковый поликарбонатный лист, экструзионная машина для производства

Пластиковая Линия для производства ПЭТ-листа

WPC ПВХ дерево пластик пена доска мебель доска кухонный шкаф доска машина цена

3 каландр дизайн автомат для производства пластикового листа для ABS PMMA PS PVC HDPE PP лист производства

Полуавтоматический экструдер для полиэтиленовой пленки SJ45/50-800 типа ABA, выдувная машина для выдувания пластика

Новые поступления

Новинки товаров от производителей по оптовым ценам