Теплоизоляционные огнестойкие вещества для полиамидов 6 алюминиевых оконных профилей

- Категория: >>>

- Поставщик: Jiangyin Kaxite Energy-Saving Materials Technology Co. Ltd.

Сохранить в закладки 62004333604:

Описание и отзывы

Характеристики

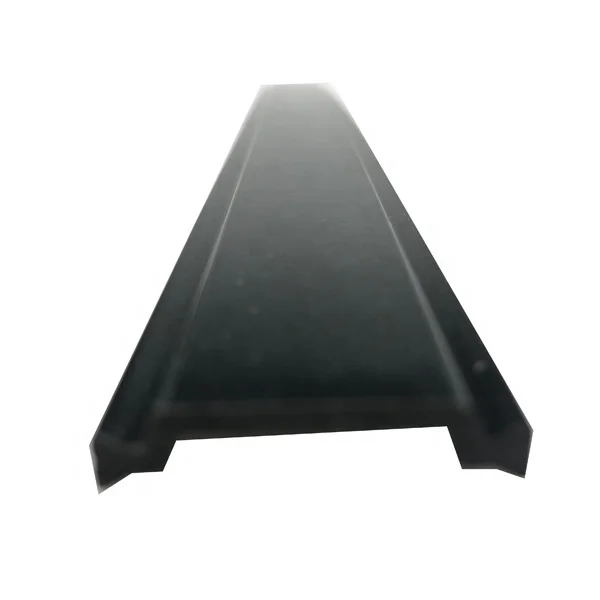

Thermal Insulation Flame Retardants For Polyamides 6.6 For Aluminium Window Profiles

Good Packaging, Take Care Of What You Care About!

Mostly we could finish the development of new products in 15 days.

The hardest thing is not thinking, but realizing. Most customers were upset that nobody could develop the shapes that they designed, some counterparts even came and looking for help to our workshop. We developing and cutting new dies for our customer, of course we never failed to develop any shape for our customers.

Service Advantages:

1, The design and development of new insulation strips, for any kinds of shapes you need for the Heat Insulation Profiles for windows & doors, we can develop mould in a short time and send you the samples, actually we’ve successfully solved so much headaches for our customers and received satisfaction;

2, We offer the most advanced laser marking machine for custmers if a special mark on the heat insulation strip is needed;

3, Here we offers most sizes from 10mm width to 60mm or even bigger heat insulating strips, which’s your best favor?

4, We provide matching equipment of PA66 thermal barrier profiles for customers for the corresponding service followed.

storage conditions:

It’s better to be stored in ventilated and dry environment, should be put horizontally, keep away from water, rain, heat, stress, and avoide acids, alkalis and organic solvents meanwhile.

Packing:

Straight: 6 m / bar, 10~100 pieces per bundle as you like.

Roll bar: 500 meters / roll (only for the shape I and shape C pieces.

An Energy-saving Materials Technology Company.

ABOUT KAXITE® TECHNOLOGY

Jiangyin Kaxite Energy-saving Materials Technology Co., Ltd (abb.: KAXITE TECHNOLOGY, KXT-TECH) was originally a family business, developing since 2001, now acting as a group, who has her own two divisions, Plastics Extrusion Division, Non-woven Division, and some high-tech cooperation projects, which supported by Nanjing University Of Science and Technology, Jiangyin Technology Bureau, Guangdong Nonferrous Metal Research Institute...

It is developing so fast and there're more than 150 employees in the group, with 2 factories, 3 offices, and 1 cooperated factory, 2 cooperated laboratories, all are located in China.

Question: Do you have MOQ requirement?

Re: No, but the extra cost for package and logistic will be charged.

Question: Can we ask for samples?

Re: Yes, samples., will be free but express fee will be charged. Only 1 day needed for making samples ready.

Question: Can we customize special shapes of polyamide profiles? How many days cost?

Re: Yes of course you can, we support cutting dies for our clients. Mostly from 15 days to 30 days. We ensure 100% successful.

Question: Can we customize package styles, such as linear 5.8 meters, or 250 meters per roll?

Re: Yes.

Question: Can we customize marks on thermal insulation strips?

Re: Yes.

Question: Why your price is higher/lower than others?

Re: We have our own capacity of granulation, to ensure the quality of thermal insulation strips, please kindly be noted that you will get the best products from us under the same price in the market.

Question: What is heat insulation profile?

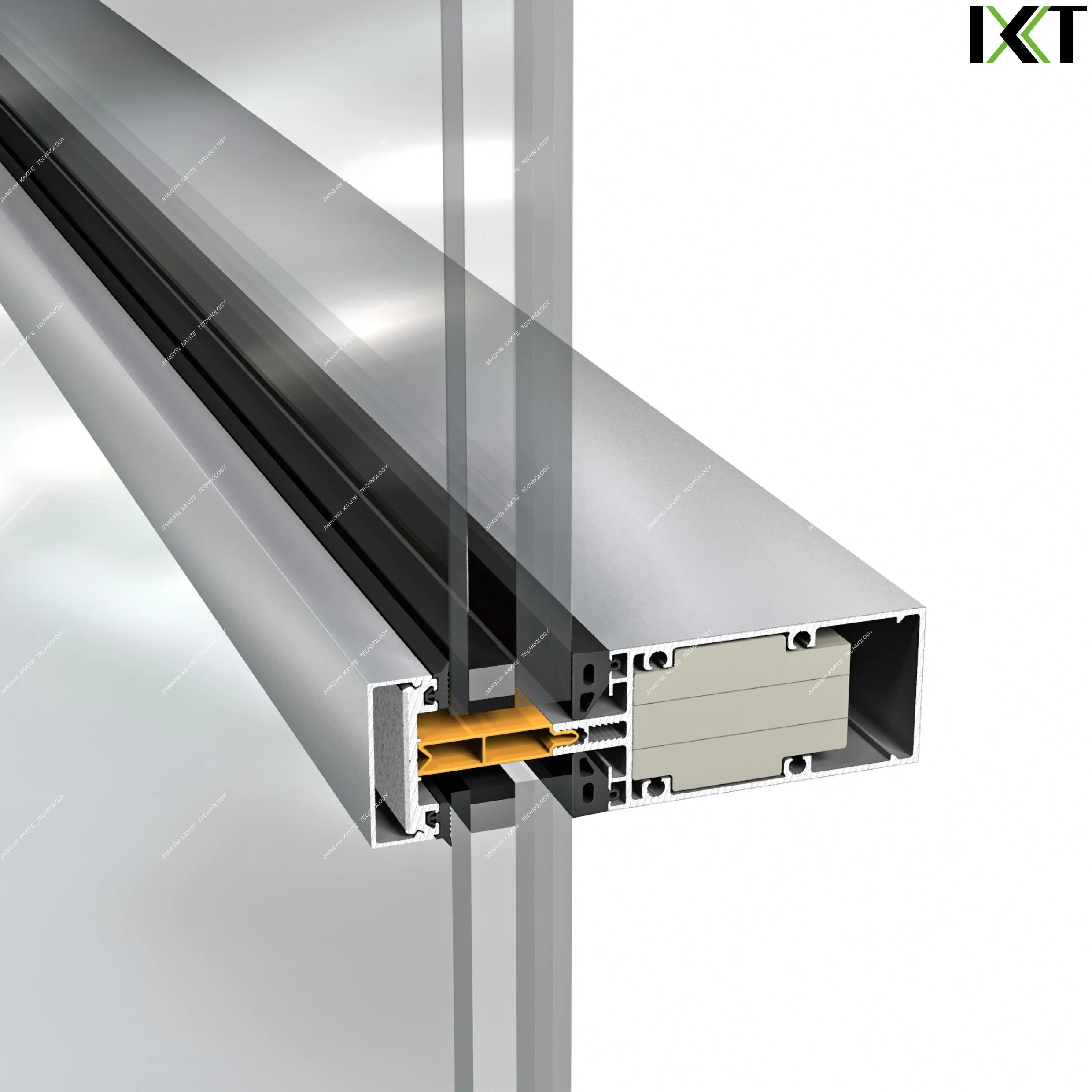

- Heat Insulation Profiles for windows & doors are made from resins that create a “thermal break” between the inner and outer surfaces of aluminum fenestrations.

- Heat Insulation Profiles for windows & doors reduce heat loss or heat gain through the aluminum.

- Heat Insulation Profiles for windows & doors improve the U-value characteristics of finished systems.

- Heat Insulation Profiles for windows & doors are about energy conservation, U-values and government codes

- 70% of aluminum fenestration systems produced in North America contain a thermal break

- Primarily used in colder climates to reduce heat loss

- Increasing use of thermal barriers to reduce heat gain and also reduce heat loss

- Developers, architects and designers are demanding better performance in terms of power usage

- Stricter government regulations to reduce power usage in buildings to combat environmental concerns

- Aluminum, if it is to retain its market superiority in terms of its structural integrity, will have to achieve better performance in terms of U-values

- The use of Heat Insulation Profiles for windows & doors will assist manufacturers to achieve improved LEED performance

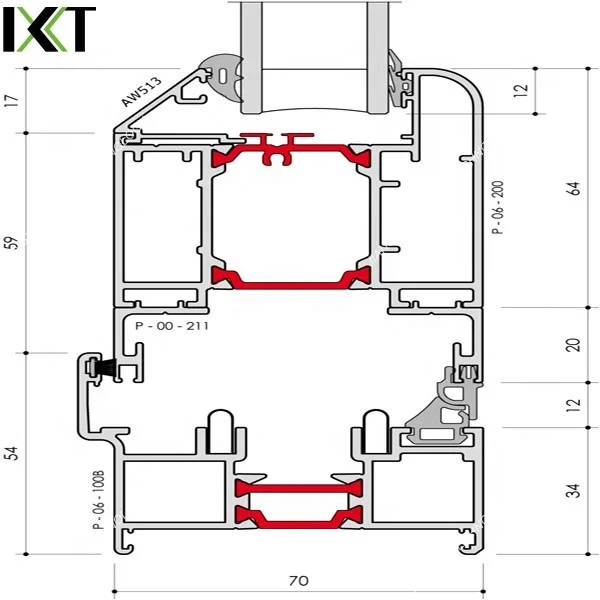

1, The Heat Insulation Profiles for windows & doors were manufactured in line with Chinese national standards GB/T 23615.1-2009, with extremely high mechanical strength and withstand tensile shear stress, can be acted as the connecter to the hardware; if you need higher properties, please choose our kaxite series polyamide profiles which were produced with pure new raw materials, most of these PA66 particles were purchased from Dupond, and all the finished polyamide profiles were in compliance with the European standard UNE EN14024.

2, the linear expansion coefficient is close to aluminum, to ensure that when temperature changes, the Heat Insulation Profiles for windows & doors and aluminium profiles expanding in the same time to ensure fitting closely;

3, highly heat distortion temperature, to meet subsequent processing on the surface of profiles;

4, high dimensional accuracy, ensuring airtight, watertight performance of the windows breaking thermo with polymer profiles;

5, anti-aging, anti-UV performance, long using life;

6, superior chemical resistance.

Похожие товары

Хит продаж пенопластовое сотовое стекло локоть ASTM C552-17 стандартные теплоизоляционные материалы фитинги

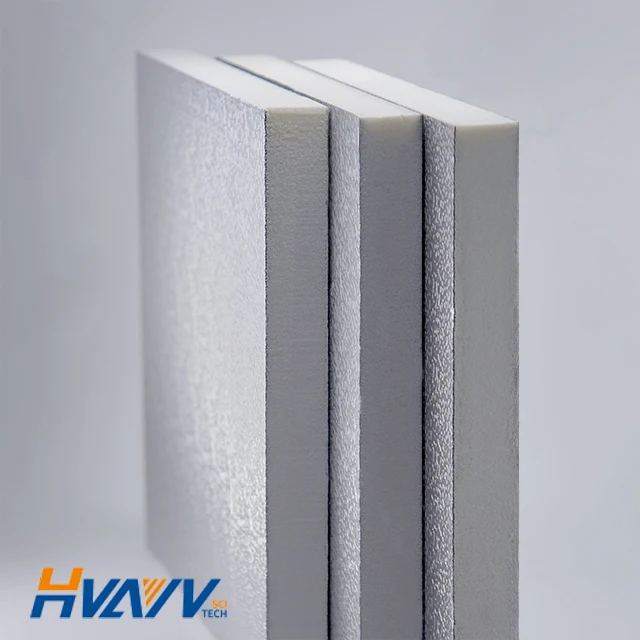

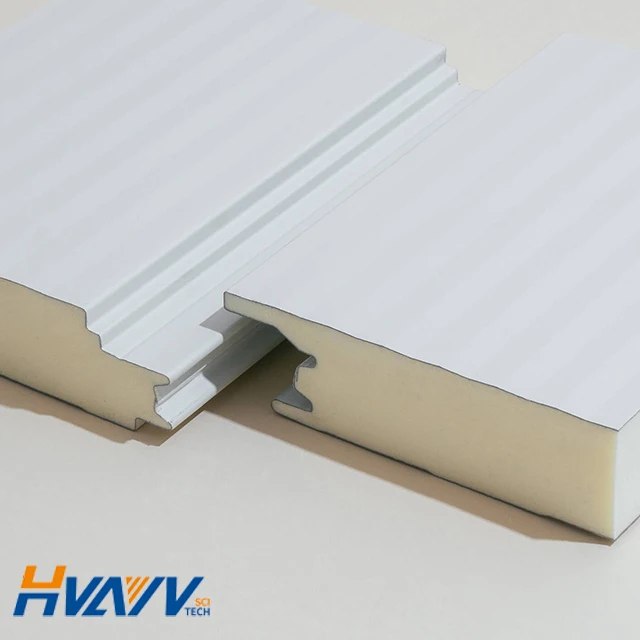

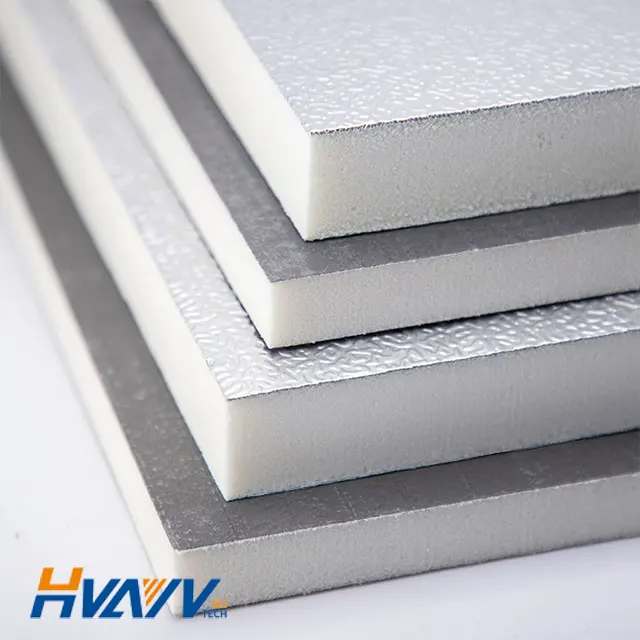

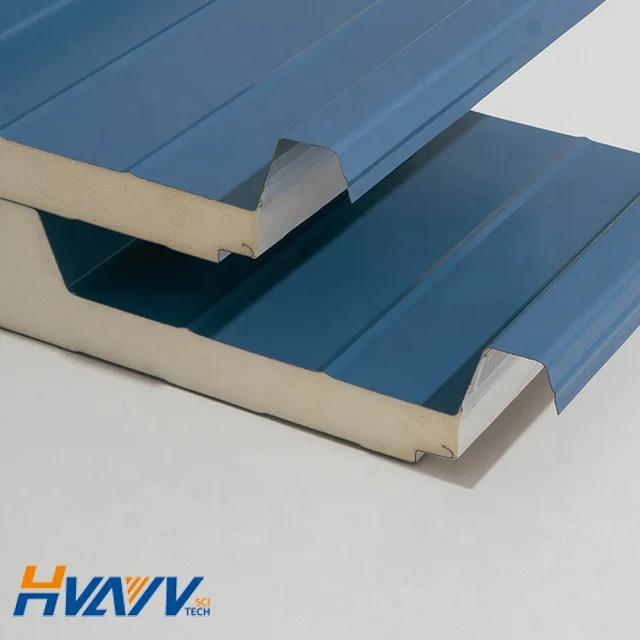

PIR PU изоляционная панель лист для изоляции крыши и стен OEM с тисненой алюминиевой фольгой

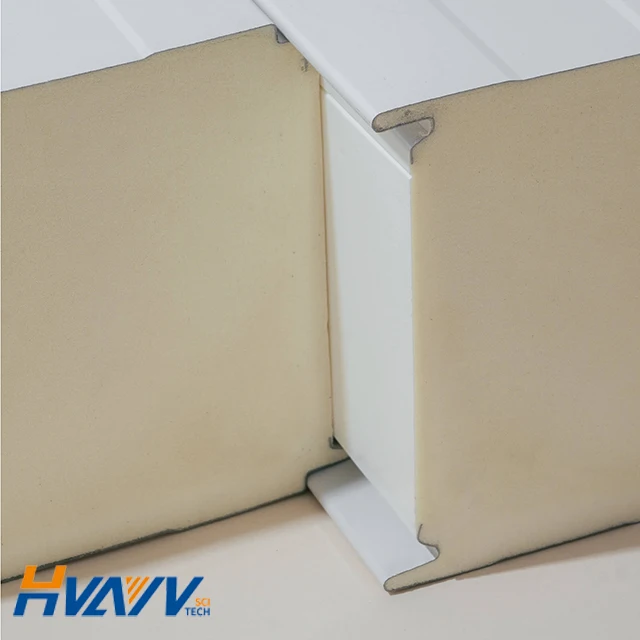

PIR PU Изолированная сэндвич-панель для крыши и стеновой панели лист холодного хранения складской OEM

OEM Легкая установка PIR полиуретановая сэндвич-панель для огнестойкой перегородки

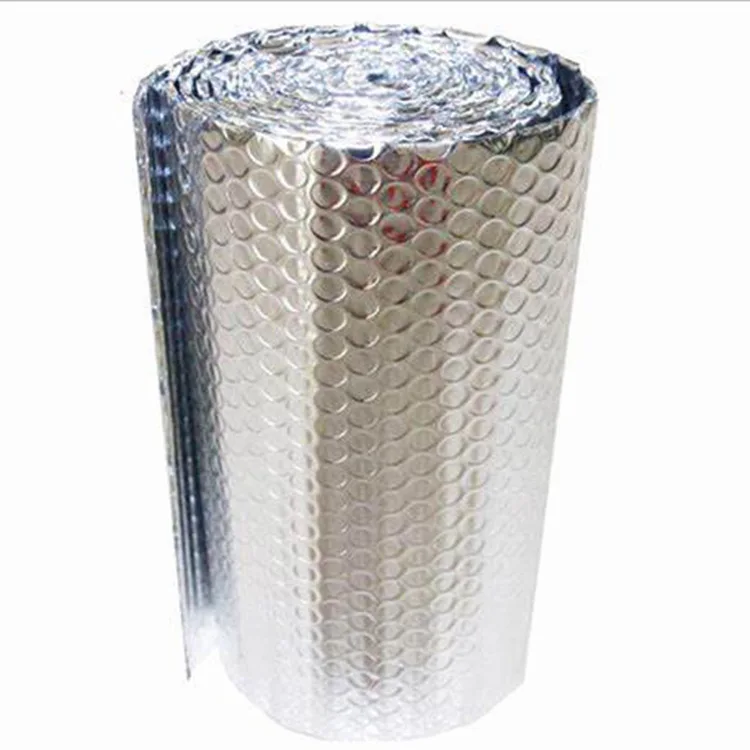

Металлическая изоляция крыши светоотражающий материал солнцезащитный козырек изоляционная куртка

PIR PU изоляционная панель лист для крыши и стены огнестойкое превосходное теплопроводность производитель продажа напрямую

PIR Pu Изолированная сэндвич внешняя стеновая панель для холодильного хранения складская крыша и стена отличная теплопроводность

Новые поступления

Новинки товаров от производителей по оптовым ценам