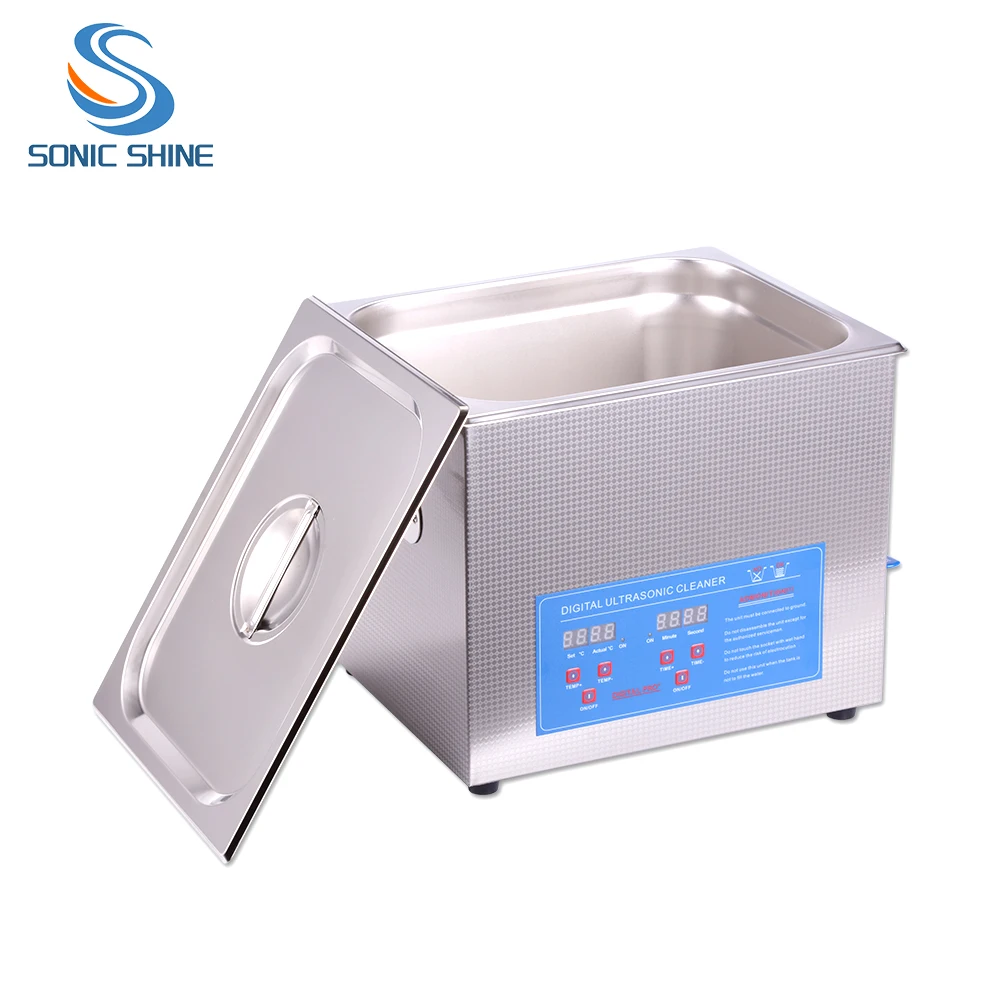

Ультразвуковая технология очищает интерьер машины для очистки блока двигателя из нержавеющей стали

- Категория: >>>

- Поставщик: Shenzhen Ag Sonic Technology Co. Ltd.Shenzhen Ltd.

Сохранить в закладки 62019565297:

Описание и отзывы

Характеристики

Ultrasonic Technology Clean The Interior Of A Stainless Steel Engine Block Cleaning Machine Cleaner

Customize a suitable machine for yourself

We have many customers with there different need of the machine, so cutomize the functions are very important.

The functions we provide normally.

1. Filter System: The most popular function for the heavy oil cleaning, like the engine/ carburetor/ heating exchanger.

With a smaller filter tank and filter bag to keep the water or detergent in ultrasonic tank clean.

Bubbling System: Usually use with the filter, some heavy sediment like scrap iron, bits of woods can not flow into the filter tank, so we need blow them onto the top of water and filtrate them.

Pump and Filtration Systems

A pump and filter system can be installed to maintain the cleanliness level of the cleaning fluid, thus saving costs in water usage, detergent dosing and heating.

Benefits of ultrasonics for filters:

Cleans delicate parts without damage

Cleans cracks and crevices that would be difficult to reach with the hand

Does not require line-of-sight for effective cleaning

Doesn’t use harsh chemical solvents that are dangerous for workers and the environment

Safe for aluminum, magnesium and zinc

Biodegradable cleaner

Clean multiple pieces at once without having to brush by hand – saves time and money

Transducer Efficiency

The efficiency of the transducer used in your ultrasonic cleaning tank will affect both the cleaning time and efficiency achieved during the cycle. A poor quality transducer will use more power and take longer to clean items than an advanced transducer.

Ultrawave have invested a significant amount of time and money into the design and development of our transducers, providing you with superior cavitation performance.

Ultrasonic Power

The level of ultrasonic power is commonly referred to in ultrasonic Watts per litre capacity. For example a 30 litre tank with 600W of ultrasonics will give 20W/litre.

In general, the level of ultrasonic power should not be less than 8W/litre although this can sometimes be reduced for very large tanks.

Ultrawave measure the power of our ultrasonic systems in RMS. This gives the total power of the transducers. Some manufacturers measure the ultrasonic power in “peak to peak” which doubles this value so it is important to compare the same measurements

ULTRASONIC CLEANING

Ultrasonic cleaning uses sound waves to create millions of small bubbles in a tank of cleaning solution. The parts to be cleaned are submerged in the solution and as the bubble are formed and “explode” they remove any dirt, grease, carbon etc. This method also works very well. The one disadvantage that I noticed with ultrasonic cleaning is that aluminum parts do not come out of the cleaning tank looking like new. They seem to have some discoloration to them even though they were clean. If you are going to paint the parts then this shouldn't matter.

Engine Parts Cleaning, Car Engine Parts Cleaning, Truck Engine Parts Cleaning, Motor Bike Engine Parts Cleaning.

AGSONIC specialising in providing Ultrasonic cleaning services and products to the industrial sector utilising the latest ultrasonic cleaning technology.

The Engine Parts division specialises in the Ultrasonic Cleaning of Engine Parts, Car engine parts, Truck engine parts and Motor bike engine parts to both trade customers and individuals throughout the World.

Our Ultrasonic cleaning process, can effectively clean the following components- Aluminum castings, engine blocks, Carburetors, Cylinder Heads, Engines, Engine Components, Gear Boxes, Filters, Tubes and Valves.

AG ultrasonic cleaning machine effectively and thoroughly clean all types of Filter Cleaning

ultrasonic tank models for your choice:

| Model | Tank size | Unit size | Volume | Ultrasonic power | Frequency | Heating power | Timer | Heater |

| LxWxH(mm) | LxWxH(mm) | (L) | (W) | (kHz) | (KW) | (MIN) | (℃) | |

| T-12S | 500x300x250 | 640x440x470 | 38 | 600 | 28/40 | 1.5 | 1-99 |

0-80 |

| T-18S | 500x350x350 | 640x490x570 | 61 | 900 | 1.5 | |||

| T-24S | 550x400x400 | 690x540x620 | 88 | 1200 | 3 | |||

| T-30S | 600x450x400 | 740x590x620 | 108 | 1500 | 3 | |||

| T-36S | 600x500x450 | 740x640x670 | 135 | 1800 | 4.5 | |||

| T-48S | 700x500x500 | 840x640x720 | 175 | 2400 | 6 | |||

| T-60S | 800x600x550 | 940x740x770 | 264 | 3000 | 7.5 | |||

| T-72S | 1000x600x600 | 1140x740x820 | 360 | 3600 | 9 |

Supply high quality product

Provide OEM&ODM service

One Year Warranty

24/7 response.

Technical support for all time.

Professional suggestion for your cleaning job.

Full inspection for every product we made.

1. AG SONIC technology limited, which engaged in ultrasonic cleaner field for more than 10 years. And the main products are ultrasonic cleaner with different capacity.

2. AG SONIC is an original ultrasonic manufacturer with R&D, production and sales teams. Our engineer is engaged in the filed for more than 20 years,

How do I perform the foil test?

Cut three small pieces of aluminum foil about 4" x 8" each. Fold each piece over a rod that you will use to suspend the foil in the tank. A clothes hanger works well. Your cleaner should be filled with an ultrasonic cleaning solution, degassed, and brought up to normal operating temperature. Suspend the first "square" in the center of the tank and the other two a couple of inches from each end of the tank. Make sure that the tank is filled to the fill line, and turn on the ultrasonics for about one minute. Remove the foil and inspect: All three pieces of aluminum foil should be perforated and wrinkled to about the same degree.

Why must baskets be used?

Items being cleaned should never be placed directly on the tank bottom. Transducers (which produce the ultrasound) are sometimes bonded to the bottom of the tank. Items resting directly on the tank bottom can damage the transducers and/or reduce cavitation. Additionally, a tray or beaker will position the item within the optimal cleaning zone of the tank. The tray or beaker will also hold the load together and allow for easy, no-touch removal, draining and transport of the items to the next step in the cleaning process

Why choose ultrasonic cleaning machine to clean our engine block and engine parts?

Clean intricate and difficult to reach areas easily

A major challenge of any cleaning system is the difficulty faced in tackling tiny spaces, intricate geometries, and difficult to reach surfaces, ultrasonic cleaning penetrates even blind holes and small apertures, that previously had hit-and miss success rates, the uniform agitation of the cleaning solution ensures that the cleaning action penetrates even hard to reach areas that previously required specialized brushes and other complicated cleaning devices with no real guarantee of a successful and consistent cleaning outcome, various factors go into determining which combination of an ultrasonic unit and chemical solution is suited to your particular requirement

For effective cleaning the ultrasonic cleaning machine must use the right of cleaning chemistry,operate at the right temperature and use the correct frequency, the part to be cleaned the contaminant to be removed and the degree of soil, determine this, our years of experience advising manufacturing and maintenance clients on the right process for their cleaning needs help us identify the exact product combo that you need, just send AG SONIC email or call us, and we’ll guide you to the right solution quickly

Ultrasonic technology uses absolutely no harmful chemicals.

No fumes. No strong odors. No dangerous or expensive chemical disposal. Reduced risk.

The technology is remarkable, but the process is easy. More efficient and effective than chemical processes, the machines are as simple to use as a dishwasher, with no hand labor or supervision necessary.

How do ultrasonic machines work?

Ultrasonic tanks generate high frequency sound waves through the use of transducers and electronic ultrasonic wave generators. Typical transducers are made from piezoelectric crystals which convert electrical energy into mechanical / sound wave energy because piezoelectric crystals change geometric size when electrical voltage is applied.

The Ultrasonic Cleaning Process

When ultrasonic energy is introduced into a cleaning solution, cavitation, the foundation of ultrasonic cleaning occurs. Ultrasonic energy causes alternating patterns oflow and high pressure phases. During the low pressure phases, minute bubbles – or vacuum cavities form.

During the subsequent high pressure phases, cavitation takes place, where the bubbles implode violently.Cavitation provides an intense scrubbing action that leads to unsurpassed cleaning speed when compared with simple soaking or immersion with agitation. Additionally, the bubbles are small enough to penetrate even microscopic crevices.

The Basic Ultrasonic Cleaning System

A generator, a transducer and a tank make up our ultrasonic cleaning system. The generator supplies electrical power to the transducer, which converts to mechanical energy in the form of pressure waves. Ultrasonic energy enters the cleaning solution in the tank, generating the cavitation that precision-cleans its contents.

Похожие товары

Цифровой ультразвуковой генератор PCB 200W-3000W для погружной преобразовательной пластины

85L 28/68k 1500 Вт Двухчастотная промышленная ультразвуковая Очистительная Машина для очистки оборудования

SN-40A 10 л умственные автозапчасти лабораторное оборудование цифровой Химический Промышленный Ультразвуковой очиститель с нагревателем дегазовый

SN-08A 1.3L автомобильные запчасти лабораторное оборудование Химический Промышленный Ультразвуковой очиститель с дегазовой очисткой

Component Cleaning Machine

Промышленная ультразвуковая Очистительная Машина с гидравлическим

DPF Очиститель Машина промышленный ультразвуковой запасные части стиральной машины сделано в Китае

Новые поступления

Новинки товаров от производителей по оптовым ценам