Производители низкая цена игральные кости высокий спрос промышленные Литые алюминиевые пользовательские Cnc подвергая механической обработке части

- Категория: >>>

- Поставщик: Shenzhen DHS Technology Co. Ltd.Shenzhen Ltd.

Сохранить в закладки 62020474588:

Описание и отзывы

Характеристики

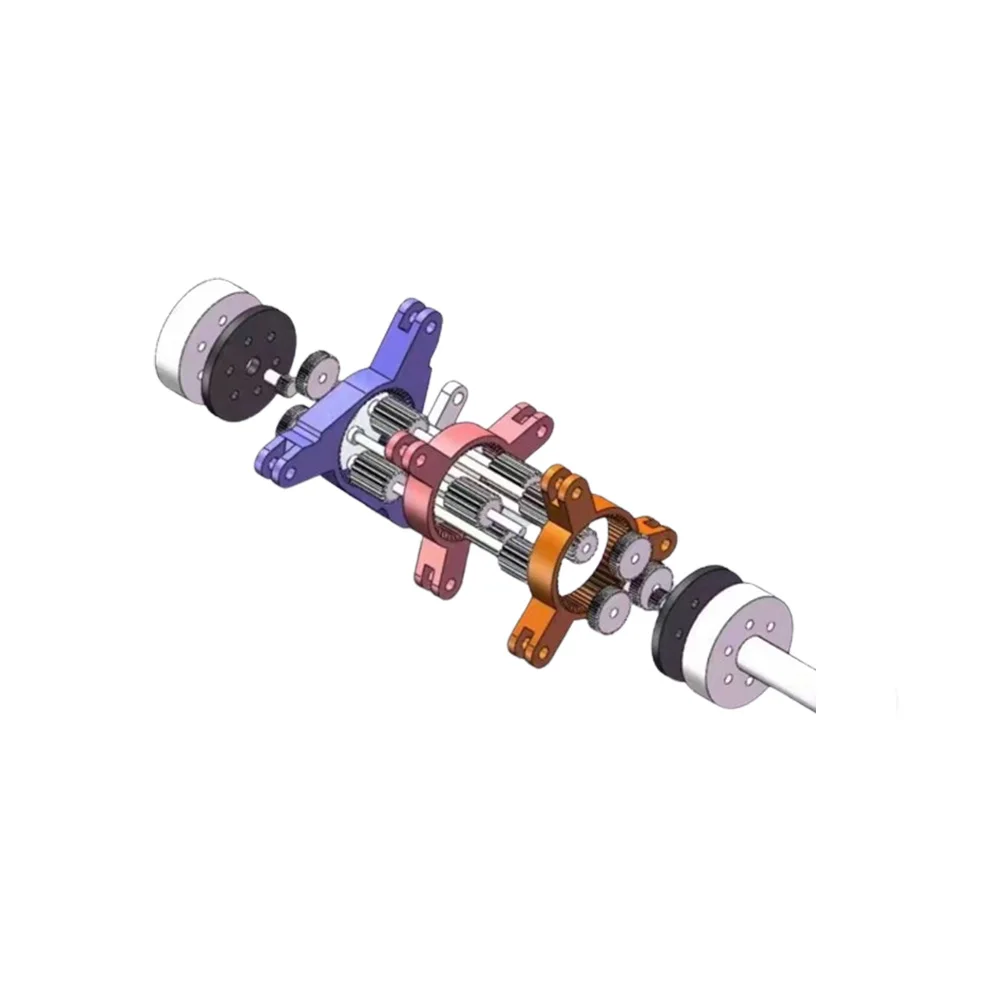

Manufacturers Low Price Dice High Demand Industrial Die Cast Aluminumcustom Cnc Machining Parts

Brief Introduction of Baton

Manufacture Range: CNC machining, Plastic Injection Moulding, Precision

Laser Cutting, and Die Casting; Service Range: Product Design, Prototype,

Surface Treatment, Integrated Processing, Assembly, Volume Manufacturing

in House.

| Product Design | CNC Machining | Plastic Mold Injection |

| From concept to engineering validation, and from design to prototype, we accelerate every step of the process. | 3/4/5 axis CNC machining center for making precision components / parts, metal, plastic and wood | High-precision plastic molding fabrication with a 780-ton injection machine for producing large plastic part. |

| Laser Cutting | Die Casting | Assembly |

| Our Laser cutting service for fabricating s.steel, aluminum, iron, copper plate from 0.5-100mm. | Gravity die casting for making mechanical, equipment, machinery, and electronics parts. |

Our product assembly finalizes the last step before your products hit the market. Save time

|

Industries We Serve

| Automobile | Electric |

| For both high-performance parts and essential mechanical components, our CNC machining services can start production from a single piece to meet urgent demands. | Our laser cutting services can transform a sheet into precise pieces within 30 minutes from the design stage. materials include aluminum, stainless steel, steel, iron, copper, brass, plastic, wood, and more. |

| Electronics | Automation & Equipment |

| Our quickly deliverable samples for high-demand products provide a tangible preview, allowing you to see and feel how the final integrated product will look and perform. | Sheet metal parts, fabricated with precision using laser cutting and CNC bending technologies, can be ready with a powder-coated or painted finish within just 2 days after order confirmation. |

| Medical | Consumers |

| Our rapid prototyping service offers a turnaround time of just 1-3 days for small-volume, high-precision medical equipment and devices. This efficiency significantly boosts your competitiveness by swiftly meeting urgent demands. | Our extensive machinery and Integrated Processing capabilities allow us to efficiently manage high-demand, complex geometry, and large-volume consumer products. |

Why Choose Us for Your New Projects?

| Substantial Cost Reductions Guaranteed | Trustworthy with 26 Years of Excellence |

| Through seamless coordination across all processing stages and unwavering commitment, we ensure significant cost savings that safeguard your projects. | With a robust 20-year history of serving over 5000 customers worldwide, we are dedicated to delivering unmatched quality and reliability. |

| Efficiently Minimizing Project Time | Streamlined Workflow Visibility |

| We meticulously review every process step to eliminate delays and optimize details, ensuring substantial reductions in overall project duration. | Get an online quote within 12 hours of inquiry, and stay updated with real-time order status through video and photo updates of the production process. |

Advantages That Set Us Apart

- Lean production

We continually optimize our production methods and human organization to enhance overall management and factory efficiency, maximizing our potential for both productivity and time savings.

- Visualization System

We have designed a comprehensive process and developed specialized software allowing us for easy and quick viewing of each product’s or project’s progress through photos and videos, ensuring transparency and efficiency.

- Automation

Our automated production processes not only reduce costs but also create conditions for improving and maximizing resource potential. This leads to enhanced product quality and overall efficiency.

- Advanced Technology

We employ the latest technology in network communication to enhance human-machine interaction and machine-to-machine cooperation, ensuring seamless and efficient operations.

Quality Management System

Our commitment to quality is unwavering. Our Quality Management System (QMS) ensures that every product meets the highest standards of excellence. This QMS include:

- Comprehensive Quality Controls: Stringent inspections and testing throughout production to ensure precision and reliability.

- Continuous Improvement: Continuous improvement, regularly updating our processes.

- Skilled Team: Experienced professionals are dedicated to maintaining quality at every stage of the manufacturing process.

With our robust QMS, we deliver products that exceed expectations and stand up to the highest industry standards.

CNC Machining

Our product assembly finalizes the last step before your products hit the market. Save time, reduce costs. Read more…

At Batnon, our CNC machining services provide precision and efficiency for your custom metal and plastic parts. Utilizing state-of-the-art CNC technology, we cater to a wide range of industries, delivering high-quality, accurate components with rapid turnaround times. Our skilled team ensures each part meets exact specifications, from prototyping to full-scale production. With capabilities to handle complex geometries and tight tolerances, we excel in producing both small and large-volume orders.

Whether you need parts for aerospace, automotive, medical devices, or consumer electronics, Batnon is your trusted partner for all CNC machining needs. Experience unparalleled quality and reliability with our comprehensive CNC solutions.

Design File Formats

We work with these design formats:

STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_ T.

1. Metal:

Aluminum alloy, Brass, Copper, Stainless Steel, Steel Alloy, Carbon Steel

2. Plastic:

ABS, Acetal Delrin (POM), PE (HDPE, LDPE), Nylon, PEEK, PET, PMMA, PC (Polycarbonate), PP (Polypropylene), PPSU, PS, PVC

3. Wood and Bamboo

FAQ:

1) What’s your advantages ?

Your mind-saving business partner ever.

Fast reaction and fast delivery, quality products, order production daily report.

2) How long is your product quality guarantee?

One year from delivery.

3) Your lead time ?

Variant depending upon order quantity. 3days delivery if stock is available, 15days for production.

4) Can you provide sample for testing?

Yes.

5) How do you dispose failure product?

Replacement with a new one.

Похожие товары

Pu комплект винтового энкодера Paguflex вращающаяся муфта вращения вала

Специальная Горячая продажа ЧПУ небольшая точность обработки деталей машин

Высокодопуск 0 005 мм прецизионная обработка с ЧПУ 5 aixs производство из нержавеющей стали титановый сплав

CNC прецизионная обработка пользовательских производителей пластиковый нейлоновый Алюминиевый Металлический Прототип 3d печать сервисные детали

Предлагает изготовленные на заказ станки с ЧПУ нейлоновых деталей пластиковой формы и комплекты латунных ламп.

Индивидуальный клеммный радиатор прямоугольный литой анодированный черный светодиодный алюминиевый на заказ

Часть из нержавеющей стали медицинские детали обработка большой контроллер Ethercat прототип инженерных услуг Cnc больничный

Новые поступления

Новинки товаров от производителей по оптовым ценам