Центробежная низкотемпературная распылительная сушилка Серии LPG

- Категория: >>>

- Поставщик: Changzhou Shinma Drying Engineering Co. Ltd.

Сохранить в закладки 62022134994:

Описание и отзывы

Характеристики

LPG series centrifugal corn steep liquor spray dryer machine

Equipment design condition

1,Liquid condition

Material name: corn steep liquor

Initial moisture content: 70%

Final moisture content: 8%

Water evaporation rate: 1150Kg/h

Liquid material temperature: normal temperature

2,Technical condition

Contact way of droplet and hot air: parallel

Heat source and heating way: natural gas and hot air furnace

Inlet air temperature: 160~200℃ adjustable(design as 180℃)

Exhaust air temperature: around 80℃

Product gathering way: two cyclone + water scrubber

Product collecting way: air dehumidifier

System manufacturing material: refer to following detailed machine configuration

3,Design weather condition

Atmospheric pressure: 101.3KPa

Ambient temperature: 20℃

Relative humidity: 80%

4,Public works

4.1,Power

Power: drive power: 219.2kw

4.2,Compressed air

Pressure: 0.6 MPa

Consumption: 1.8m3/min

4.3,Occupied area (L × W ×H): 20m×12m×18m

4.4,Pure water consumption

1000kg/time(use when temperature rising and dropping)

system description

Machine model: LPG-1150 Spray Dryer Unit

Heating system: direct Heating Natural Gas Hot Air Furnace

Fine powder gathering system: two cyclone + water scrubber

Product collecting system: cooling air dehumidifier, negative pressure

Circulating system: blower+ exhaust fan open circle

Firing system: primary + middle efficiency+ HEPA

Feeding system: screw pump adjustable

Control system: Digital instrumentation display temperature, pressure, pressure, touch-screen animation flow chart, focused set of parameters, PLC technology to automatically track the control variables of fuzzy parameters, etc.

Features

1. Drying speed is fast. Material is atomized and superficial area is increased greatly. During contacting with hot air, 95%~89% moisture will be evaporated instantly. Drying time just need seconds, so it is suitable for drying thermal sensitive materials.

2. The product has good degree of homogeneity, fluidity and solubility

3. Production process is simple and operation is easy to control. Liquid can be dried to powder product one time, and after dried crushing and sieving is not needed, so the production steps are reduced. The particle size, density, moisture content of product can be adjusted and controlled by changing operation condition.

4. Adopts mechanical type centrifugal atomizer, driven by gear, rotary speed is stable and can ensure the uniform distribution of forgdrops

5. The direction and angle of hot air distributor adopt adjustable structure, it can ensure the forgdrop contact with hot air fully.

6. Elbow is made of sanitation degree steel pipe, it can avoid the material blocked in the elbow.

Похожие товары

Натянутые холсты с логотипом на заказ

Пластиковый дверной направляющий Лифт KONE, пластиковый дверной слайдер KM997109H01, бесплатный образец

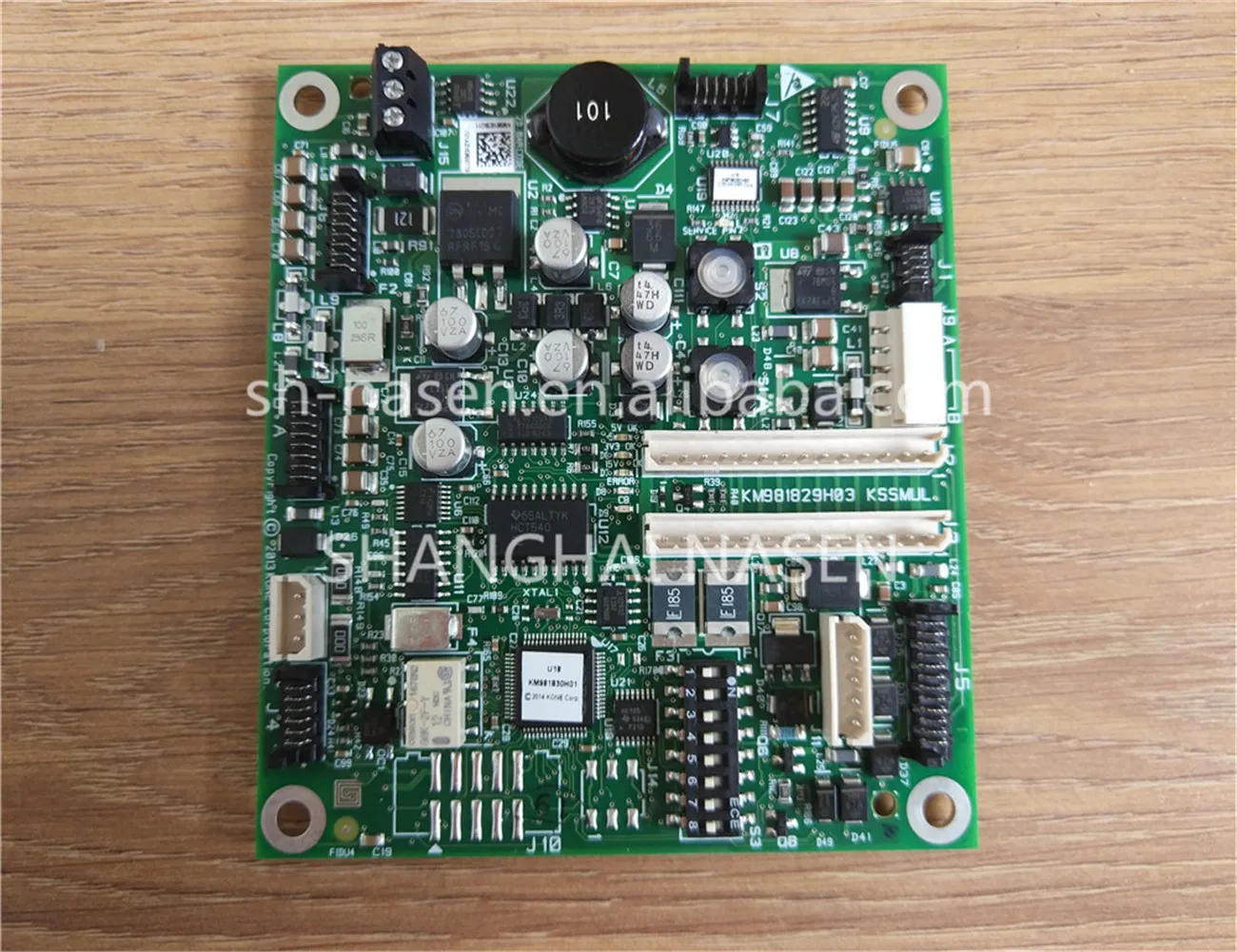

Лифт kone печатной платы KM713730G11

Лифт KONE 772853H06 f2kul KM772850G02

Цинковый сплав, овальная форма логотип одежды теги дизайн открытое письмо никель, открытый подъем, фирменные отверстия метка частного назначения

Пистолет для массажа тела и ног треугольный прибор с большой амплитудой пистолет

Запчасти для лифта KONE, подъемник из ПВХ, скользящая направляющая втулка, направляющая втулка для обуви

Новые поступления

Новинки товаров от производителей по оптовым ценам