Устойчивый ударный Материал PC/PBT UV из сплава и пластика для электрических корпусов электрические аксессуары электроника

- Категория: PBT >>>

- Поставщик: T&T Industry (Shenzhen) Co. Ltd.

Сохранить в закладки 62025119094:

Описание и отзывы

Характеристики

PC/ABS Alloy

| Mechanical Properties | Standard | Condition | Unit | Value |

| Tensile Strength | ASTM D638 | 50mm/min | Mpa | 51 |

| Elongation at Break | ASTM D638 | 50mm/min | % | 115 |

| Flexural Strength | ASTM D790 | 3mm/min | Mpa | 80 |

| Flexural Modulus | ASTM D790 | 3mm/min | Mpa | 1970 |

| Izod Impact, Notched | ASTM D256 | J/m | 625 |

PC/PBT has high surface hardness, high rigidity and toughness, high resistance to high temperature, and high anti-stress cracking ability.Its mechanical properties are somewhere in between

The high temperature deformation is of great significance for large shell products.

1) Automotive Industry: door handle, bumper, distributor, vehicle gear parts, ignition coil skeleton, insulation cover, exhaust system aparts, motorcycle ignition device;

2) The electrical and electronic industry: such as TV deflection coil, kinescope and potentiometer bracket, audiooutput transformer skeleton, adapter framework, switch connector, electric fan, refrigerator, washing machine motor end cover, shaft sleeve;

3) Household appliances: transport machinery parts, sewing machines and textile machinery parts, watch shell, lens barrel, electric iron cover, oven parts, electric tool parts, shielding sets.

PC/PBT material for Air fryer:

PC/PBT material for Sweeping robot:

PC/PBT material for Car door handle:

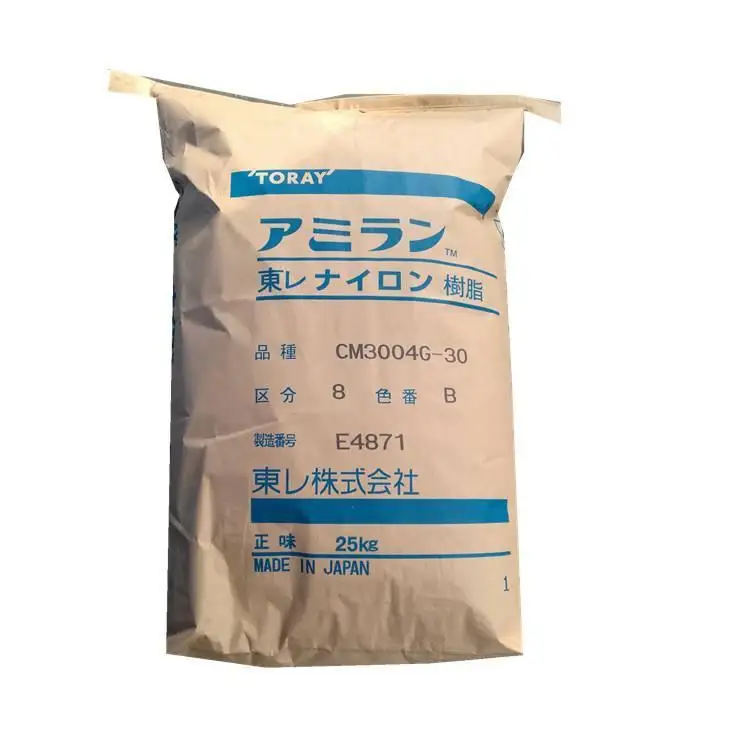

1. Waterproof Design(Dual package, Waterproof bag Inside)

2. Sealed Packaging,Impact resistant (Kraft paper bag+PE/Aluminum liner)

3. Customized package (25kg/bag or 500kg/bag)

4. Water-proof , Anti-breaking,Anti-extrusion . Anti-heavy throw

5. Transporation by sea, the sample can be shipped by air.

T&T Industry Group Ltd is a customized engineering plastics company combining of R&D, Design, and Project Development. Currently our focus is on the project devlopement and optimal configuration of different resources, based on the actual situation of the One-Belt and One-Road industrialized countries and current new materials development, and world industrialized situation.

Service procedure:

Consulting--solutions--quotation--sending samples--quality check--placing orders-- customization--deliver goods--after sell services

1.Technical backgroud Sales can provide in-time and professional responses to customers' inquiries.

2. Real-time Quality Inspection Tour in full production process;

3. Certicate of Analysis provided for each delivery of goods

4. After-sales quality tracking and feedback

5. Customers complains processing management system to guarantee the consistant improving service to each client.

1.Samples leading time : 1-2 weeks after passed our test;

2.Bulk order leading time : 2-4 weeks ( customized materials ,seldom in stock)

3.Samples are delivered by FEDEX DHL ,TNT , UPS,Samples fee will be refund when the first bulk order comes .

4.Payment Term: T/T or L/C at sight;

5.Minimum Order Quantity: 1 MT

6.Delivery Time: Lead-time is around 7-14 working days after we receive the advance payment. It varies according to different products and quantity.

7,.he quality standard refers to the sample. And quality issues we provide free tech-support

--

Похожие товары

Теплопроводящий PBT гранулы пластикового сырья pbt gf40 частиц

Быстрая доставка Чистая PBT смола для ПВХ кабелей и проводов-полибутилентерефталат

Японские гранулы для литья под

TORAY PBT GF20 Toraycon 5174G-X11 Смола гранулы 20% армированного стекловолокном

PBT натуральные пластиковые гранулы инженерного класса gf30 пластиковое

Лидер продаж 2023 гранулы из молочно-белого Пт-стекла высокого качества изготовленные экспортерами для промышленного

Китайский завод PBT 1101G-30 армированный стекловолокном огнестойкий и

Новые поступления

Новинки товаров от производителей по оптовым ценам