Высококачественная печь для вакуумной дистилляции кадмия

- Категория: >>>

- Поставщик: Hunan Chmm Metallurgy Engineering Co. Ltd.

Сохранить в закладки 62068759949:

Описание и отзывы

Характеристики

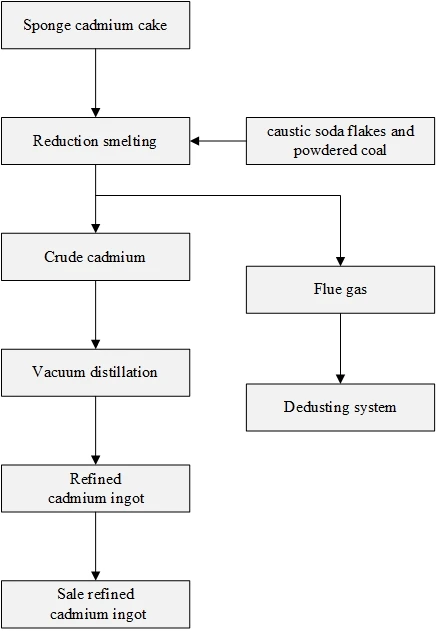

1.Process principle

Raw material and Products

Process flow Process Principle

Process Principle

The Principle of Refined Cd Vacuum Distillation

The temperature requires 761K of the Cd to reach the 1.33*10³Pa vapor pressure in the vacuum environment, and 888K to reach the 1.33*104Pa vapor pressure. The low-boiling point of Cd liquid is heated and vaporized in the crucible, the vapor separates from the liquid surface and flows to the top where the vapor saturation is lower, when passing through the reflux tray, the metallic vapor that boiling point higher than the Cd and part of Cd vapor would be condensed and return to the crucible, and most of the low-boiling Cd vapor would be condensed to the refined Cd liquid(99.995%) in the inside of the condenser that above the reflux tray.

Input:1600-2000kg/8h continuous automatic feeding

Temperature:Between 550~600 ℃

Condensing temperature: Between 360~460 ℃,

Ingot casting of Refined Cd:

Continuous automatic feeding to the Ingot casting machine

2. Key Equipment

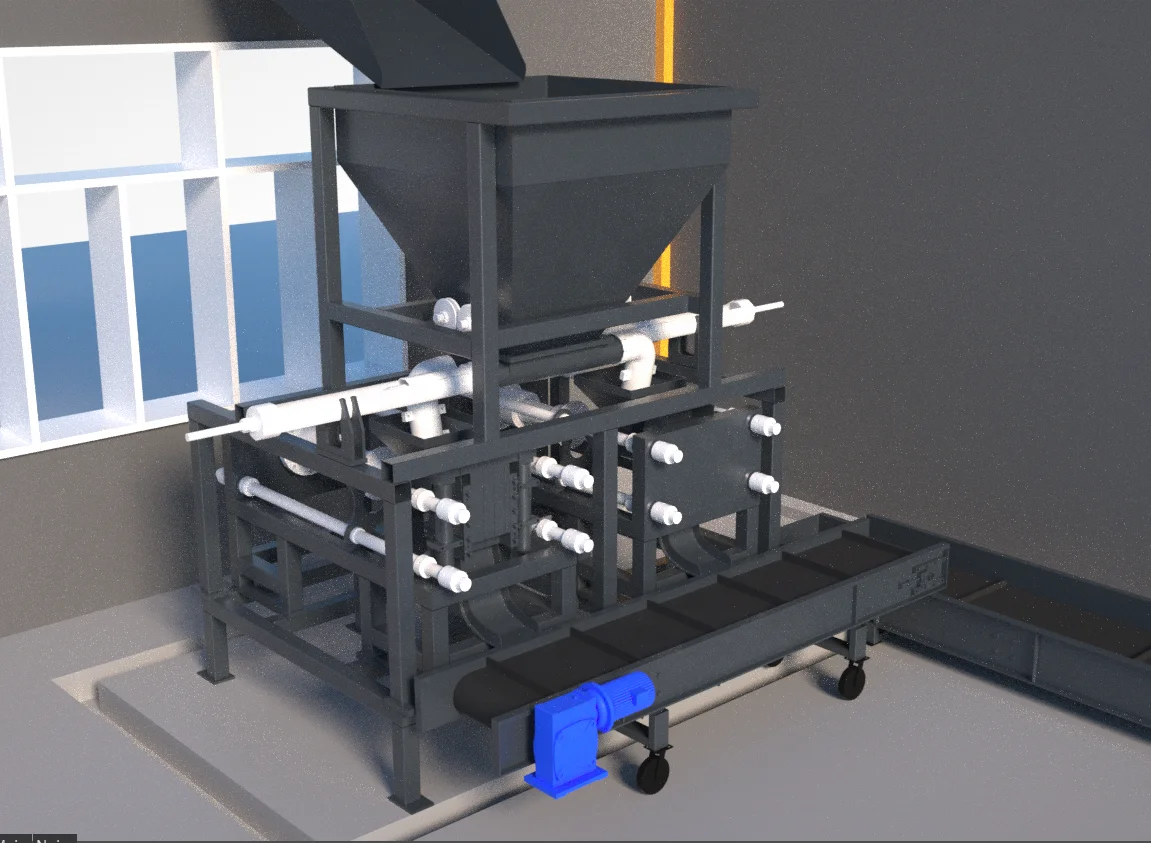

Cd Briquetting Machine

Cd Briquetting Machine

Item | Description |

Single mould weight | Weight around 2.85kg, diameter150, thickness 50mm |

Working Frequency | Around 80kg/hour per single |

Compression ratio | Around 3:1 |

Single pressure | Single pressure above 100 tons, single intensity of pressure 20~25MPa |

Cd briquetting diameter | 150 mm |

Cd briquetting thickness | 50 mm |

Cd Moisture after briquetting | Average less than 8% |

Site space | 5.6*2*1.8n, oil cylinder:2*1*0.7m, Feeding machine: around 0.8m long |

Cd Vacuum Furnace

Cd Vacuum Furnace

Main Component

1.Melting furnace

2.Vacuum distillation furnace

3.Holding furnace

4.Vacuumizing equipment

5.Weighing sensor

6.Pressure transmitter

7.Heating plate of vacuum feed pipe

3. Main technical and economic index

| QTY | Unit | Remark |

Raw material treating capacity | 10 | Ton | Sponge Cd |

Product quality | 99.995% |

| Refined Cd |

Comprehensive recovery rate | 98% |

|

|

Water consumption | 1 | ton |

|

Power consumption | 2000 | kwh/t | Refined Cd |

Gas consumption | 4 | Cubic metre/ times furnace shut down | Nitrogen |

Coal powder | 136 | kg/ton | Sponge Cd |

Caustic soda flakes | 200 | kg/t | Sponge Cd |

People | 3 | People/shift |

|

Site | 600 | Square meter | Equipment space |

Crane | 5 | T | 8 meters high |

Construction cycle | 120 | day |

|

Equipment production time | 60 days | day |

|

Equipment installation time | 40 | day |

|

Equipment adjusting time | 2 | day |

|

Equipment commissioning time | 18 | day |

|

4. Reference

Hulun Buir CHI HONG Mining Industry

MENGZI Mining & Metallurgy Co, Ltd

WESTERN Mining

Nang FanNonferrous

Xiang Xi Tai Feng

China has ranked as the world’s largest producer of nonferrous metals with its fast economy growth over the last two decades. After continuously making efforts on tackling key technological problems and accumulating a wealth of experiences in practice, now CHMM are delight and ready to share the CHINESSE EXPERIENCE, COST-EFFECTIVE PRODUCTS AND SERIVCES with all friends in nonferrous beneficiation and metallurgy industry all over the world.

CHMM is providing the most advanced technology and services for sustainable use of nonferrous resources of earth, mainly to provide energy saving, environmental protection, high quality and efficient producing technology, equipment and services for the Copper, Lead, Zinc, and Tin and other nonferrous smelting industry.

CHMM provides extensive and flexible business cooperation models for domestic and overseas customers, including research, design, equipment supply, installation, commissioning, training, test run and operation.

Packaging Details: vacuum distillation furnace packing:Plastic wrapping film and wooden pallets

- Port: Shenzhen,Guangzhou or Shanghai

Pre-Sales Service

* Inquiry and consulting support.

* Factory visit support

* Sample testing support

After-Sales Service

* Training how to install the furnace, training how to use the furnace.

* Engineers available to service machinery overseas.

Please kindly contact us at below information if you have any demand

Похожие товары

Коврики для мыши с изображением кошек и карт мира для девочек, Нескользящие большие компьютерные коврики, большие коврики под заказ

Женский сетчатый корсет в готическом стиле, корсет-бюстье для похудения и коррекции талии

Кабель питания Tfl DC для медных проводников, 600 в

Маленький Металлический Настенный одинарный крючок для супермаркета, розничная продажа, хромированная настенная клейкая панель, крючки для висячих вещей, аксессуары для одежды

Полуавтоматический стеклянный погрузчик, стол для резки стекла для большого стекла

Usb Car Socket Charger Dual / 2 Port Charging Port DC 12 V/24V Cigarette Lighting Mobile Phone/camera/pda/mp3 CE ROHS FCC 534A

WUBEN E18, тонкий и компактный хвостовой переключатель с позолоченным покрытием

Новые поступления

Новинки товаров от производителей по оптовым ценам