ПП светодиодные лампы пластиковый сварочный аппарат для пластиковых шариков круглая светодиодная лампа крышка термофьюжн спиннинговая Сварка пластика сварка

- Категория: >>>

- Поставщик: Shenzhen Keepleader Machinery Co. Ltd.Shenzhen Ltd.

Сохранить в закладки 62076055929:

Описание и отзывы

Характеристики

PP LED Bulbs Plastic Welding Machine of spin welding

PP LED Bulbs Plastic Welding Machine of spin welding is used for welding ♦1: Water filter ♦2: Oil filter ♦3: Mug ♦4: Thermo Cups ♦5: PP pipe/tube ♦6: Barrel and other related circular /Spherical shaped thermoplastic parts

PP LED Bulbs Plastic Welding Machine of spin welding

01: Parameter

Model | KLP-1500 |

Power | 1500w |

Power supply | 220v/60hz or 380w/50hz*3P |

Working pressure | 0.5~0.7mpa |

Welding Area | Diameter: 100mm |

Motor speed | Max 1500 RPM |

Rotation Circle | 30 adjustable |

Torsion | 10N*M |

Delay time | 0~100 seconds adjustable |

Hold time | 0~100 seconds adjustable |

Net weigh | 230kgs |

Overall Dimension | 750*850*1980mm |

PP LED Bulbs Plastic Welding Machine of spin welding is according to the product size and use material, the machine specification can be modified

02: Application

Spin welding plastic products together such as floater, paint tank, spherical toy, PP thermos cup, oil filter (for motor bike), water filter, spray connector, thermos bottle interior and etc

Material consideration: Material suitable for spin welding are generally the same as those that can be joined by other friction welding processes, such as vibration welding, semi crystalline thermoplastic are more readily joined using spin welding that ultrasonic, using compatible polymers spin welding is capable of making reliable hermetic seals, joining of dissimilar polymers is possible using the spin weld process, although it generally produces lower strength weld joints, by designing the weld joint with an under cut, the polymer with the lower melting temperature will flow into the undercut, creating a mechanical union, material filler and surface contaminants (e.g. mold release agent) are two factors that will affect consistency and weld repeatability, spin welding is more tolerant of contaminants that ultrasonic welding, spin welding is also less affected by hygroscopic polymers, although they may still require special handing from critical application

Joint design consideration: Part joint must be circular (other part geometry may be non-circular), joint type should be selected to meet welded assembly requirements, joint design should allow for adequate collapse / melting distance, the part to be mounted in the spinning tool on the machine should have driving features so that torque can be transmitted from the tool to the part

Control parameters: Linear speed at the weld joint (based on spin RPM), press (axial) speed, weld depth, hold depth and hold time, the setting for these depends on parts size, material joint design

03: Spin welding machine step

STEP1: The two thermoplastic parts to be welded are loaded into the machine, typically one into the spin tool and the other into a stationary supportive nest call a fixture

STEP2: After a circle is initiated, the spin tool descends toward the fixture while simultaneously accelerating to the programmed weld spin speed (RPM).

STEP3: After the parts come into contact with each other, the tool continues to spin at a constant speed (RPM) while the press forces the parts together, causing the interface to melt, the spinning stops once the programmed condition for ending the weld is met, such as reaching the programmed part collapse distance.

STEP4 Once spinning stops, the hold phase follows, typically consisting of dynamic hold and static hold. During dynamic hold, the press is advanced to further collapse the parts while the plastic material is still molten. During static hold, the press position is maintained while the material cools and solidifies.

STEP5: The spin tool retracts. The two plastic parts are now joined as if molded together and are removed from the machine as one assembly.

04: High Lighting of Spin Welding

Ability weld parts with circular joint that are not easily welded by ultrasonic

Relatively fast circle times compared with other methods

Compatible with most thermoplastics

Ideal for welding of PP, PE, Nylon round articles

Ability to weld several dissimilar materials

No consumables. Fumes remissions

High strength, hermetic welds are typical

Heat confined to weld interface

Easily automated

Low lost, quick change tooling

Low maintenance

Low power consumption

PP LED Bulbs Plastic Welding Machine of spin Welding is the preferred technique for thermoplastic parts with a circular axis joint which have high bond strength/hermetic requirement, during spin friction welding, one part is held stationary in a pneumatic holding fixture while a second part is rotary against it under pressure at speeds up to 16000rpm, this resulting friction causes the joining surface to melt and fuse together, producing strong hermetic welds

PP LED Bulbs Plastic Welding Machine of spin welding comes with Customized Clamping device+spinning actuator, which will made with your drawing or samples

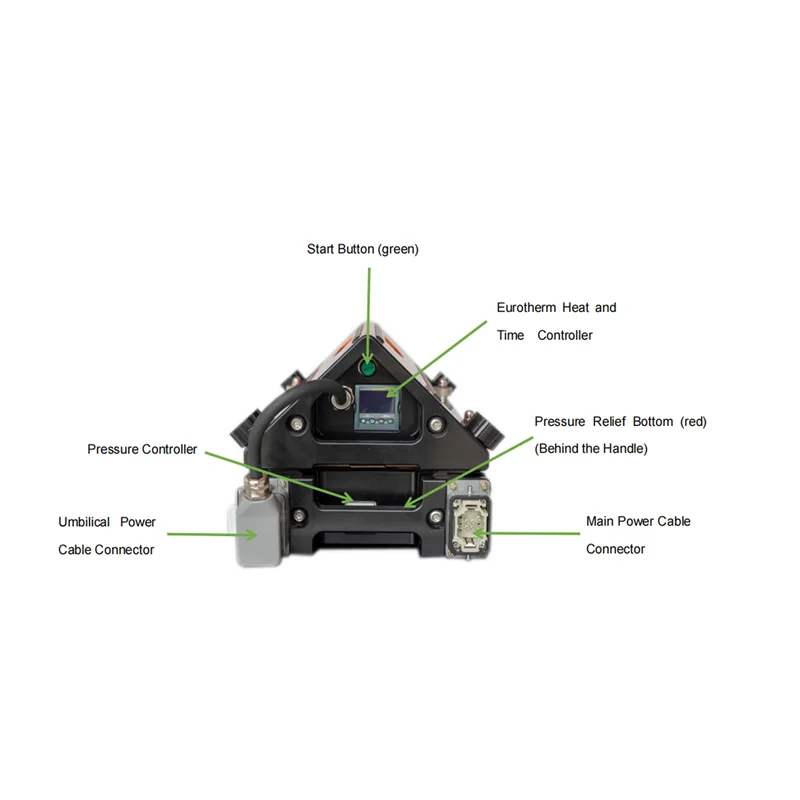

Functional illustration of PP LED Bulbs Plastic Welding Machine of spin welding

PP LED Bulbs Plastic Welding Machine of spin welding may be applied in floater, paint tank, spherical toy, PP thermos cup, oil filter (for motor bike), spray connector, Thermos bottle interior...etc.

Pls contact Ms Helen By E-mail: sales (@) keepleader.com for PP LED Bulbs Plastic Welding Machine of spin welding

Cellphone/Wechat/Whatsapp: +86 13590415784 / Tel: +86 755 84190358

Website: www.keepleader.com

Похожие товары

Тестер утечки давления воздуха для проверки качества геомембранной сварки

Автоматический ультразвуковой сварочный аппарат для производства поперечного вентилятора полипропилен/брезент

Оптовая продажа китайский полипропиленовый/брезентовый полевой аппарат для обслуживания и ремонта ПВХ-ленточный сварочный

Клиновый сварочный аппарат WELDY WGW 300

Высокомощный ультразвуковой пластиковый сварочный аппарат для AC воздуходувки

2000 Вт ручной привод вязальная машина полностью автоматическая стальная пластиковая геосетка сварочная ползающий сварочный аппарат

15 кГц 20 полый гофрированный ультразвуковой сварочный аппарат для пластиковой коробки

Новые поступления

Новинки товаров от производителей по оптовым ценам