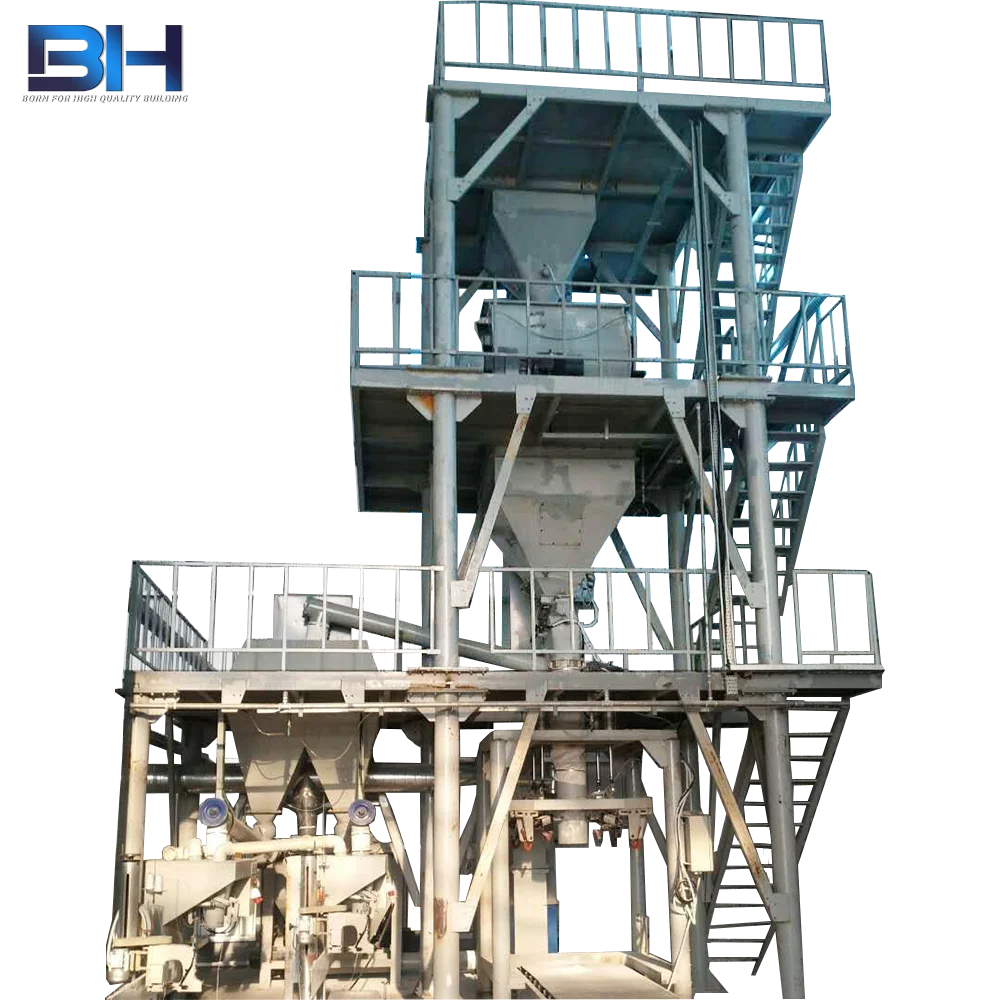

Automatic Dry Mortar Mixing Machine Production

- Категория: >>>

- Поставщик: BH Mortar Industrial Co. Ltd.BH Ltd.

Сохранить в закладки 62082664977:

Описание и отзывы

Характеристики

Automatic dry mortar mixing machine mortar production line

| Description of automatic dry mortar mixing production line |

BH Automatic dry mortar plant on the basis of semi-auto dry mortar plant, increases the raw material storage system, automatic weighing system and premix tank, that no need manual weighing, and improves the efficiency. Depending on the configuration, capacity at 10-35T/H, with an annual output of 30-100,000 tons per year. Occupation area: 60-100m² , Height: 8-13 m, Worker required: 3-5 person.

Main configuration

Electric control cabinet; Cement silo, Weighing system; Feeding hopper; Impulse dust collector; Bucket elevator; Premix tank; Twin shaft agravic mixer; Finished product holding tank; Automatic packaging machine; Air compresser.

It can be equipped with grinding machine and drying machine according to requirement.

Bonding mortar: Masonry mortar, wall and floor tile adhesive mortar, tile glue, anchorage mortar etc.

Decoration mortar: Decorative plaster, Thin set coating, inner and outer wall putty, Screed mortar, colorful decoration mortar etc.

Protection mortar: Water-proof mortar, anti-corrosion mortar, self-leveling mortar, wear resistance mortar, thermal insulation mortar, sound insulation mortar, AAC jointing mortar, dry sand mixture, repair mortar, mildewproof mortar, shielding mortar etc.

If your capacity is above 35t/h,you can choose our Station type dry mortar plant

|  |  |  | |

| Model | Simple dry mortar plant | Improved Simple dry mortar plant | Semi automatic dry mortar plant | Full automatic dry mortar plant |

| Out put | 1-3t/h | 4-5t/h | 5-8t/h | 10-30t/h |

| Components | screw conveyor, horizontal ribbon mixer, storage tank, packing machine, control cabinet, air compressor | screw conveyor, twin shaft mixer, storage tank, packing machine, control cabinet, air compressor | bucket elevator, twin shaft mixer, holding tank, packing machine, control cabinet, air compressor | cement silo, screw conveyor, automatic weighing system, bucket elevator, premix tank, twin shaft mixer, holding tank, packing machine, automatic control cabinet, air compressor |

| Occupied area | 20m² | 20m² | 50-60m² | 60-100m² |

| Total power | 5.5-7.5kw | 6-11kw | 24-28kw | 60-120kw |

Mixer volume | 3300*1050*2100(mm) | 2m³ | 2m³ | 2m³, 3m³, 4m³ |

| Equipment height | 3-4m | 3-4m | 6-8m | 8-13m |

| Man power | 2-3person | 2-3person | 3-4person | 3-4person |

| Batching and packaging | Manual batching & Automatic packaging | Manual batching & Automatic packaging | Manual batching & Automatic packaging | Automatic batching & Automatic packaging |

BH Dry mortar plant main components advantages |

BH Twin Shaft Paddle Mixer 1. High mixing homogeneity at 99.9% |  |

| Modular steel structure Our dry mortar plant's steel platform design in modular structure which born for export market. It can reduce the packing space, save the transportation cost, and it is more convenient to install when it arrives at the site, saving the installation time and the installation cost. |

Raw Material Storage Tank Our bolted cement silo is also born for export market, not only has excellent quality,reliable sealing structure.but also easy for transportation, easy for assembling, easy for disassembling, save shipping space, reduced transportation cost. |  |

| Automatic Weighing System We equip with advanced weighing system which has features of accurate, stable,reliable.etc. Autoamtically weighing raw materails accordingly to the formulation, high precision, reduce weighing error,save labor cost, improve the output. |

| Other Main Components Details and Features |

PACKAGING & DELIVERY

Packaging

1, HS code can be supplied to you for checking importing tax in your country.

2, Standard export packaging by container, which should be applicable to international requirement.

3, Big size equipment will be fixed by steel wire, while small ones together with spare parts will be packed into wooden boxes.

4, Standard configuration: 2X40HQ container for 1 set 10t/h dry mortar plant.

Shipping

Usually by sea, sometimes by land, air.

Delivery time: 15-30 days after deposit arrived

The reason you choose us:

» The structure we designed is advanced and compact. According to your site and capacity, we can provide you reasonable design with factory price.

» Cooperated with Shanghai WEIPU Institute (www.weipuchem.com),then we supply advanced construction materials formula and top rank additives together to ensure the end products good quality you produce.

» Our professional installation team has rich experience to complete the installation, commissioning fast, and also to train workers how to operate, maintain the equipment.

» As a professional and highly experienced manufacturer of dry mortar mixing equipment in China for more than 20 years. We are in the leading position in this scopes.

Q: For providing you the suitable quotation we need to know the following information:

1. What capacity do you need?

2. How many raw materials you use? What's the estimate ratio?

3. Is sand dryer required in this system? What is the fuel you use, coal? gas or diesel?

4. Regards packing, how many kg per bag do you need?

Q:What equipment and services you can provide?

We can provide you turnkey solution of dry mortar manufacturing machine from working site planning to dry mortar machines, transportation, installation and training, formula of dry mortars, after-sales services, life time technical support etc .

Q: What about Warranty of the products?

The BH Machinery grants our customers a twelve-month-period warranty from the date of delivery for machines exported from us. During the warranty period, in case any defect of material or workmanship occurred with spare parts in normal operation, we will at our discretion replace or repair the defective parts freely.

If you want to know more of our dry mortar manufacturing machine, please send us inquiry or contact us directly.

Похожие товары

скульптура Будды

Cheap China Export Wholesale Loose Small Gemstone Peridot Chips Green Stone for

показывает некоторые кожные чашками на косточках атласный бант милые девушки рождество сексуальные игры babydoll

2024 Fren Factory Double Arc Rechargeable USB Lighter Hot Sale in

Прозрачный акриловый контейнер для конфет из плексигласаПрозрачный

WE New Design Office School Furniture Sleeping Bunk Bed Pod Indoor Double Capsule for

Glass Dropper with Nitrile Rubber

Новые поступления

Новинки товаров от производителей по оптовым ценам