Линия по производству гамбургеров оборудование для хлебопечки машина производства линия

- Категория: >>>

- Поставщик: Shijiazhuang Bake Machine Tech Co. Ltd.

Сохранить в закладки 62087035232:

Описание и отзывы

Характеристики

Hamburger Making Machine

/Bread Production Line for sale

Rotary oven Model | tray dimension | Energy | Voltage | Power |

BK-D16E | 400*600mm&460*660mm&460*720mm/16 | electric | 380V | 52KW |

BK-D16D | 400*600mm&460*660mm&460*720mm/16 | diesel | 380V | 3.3KW |

BK-D16G | 400*600mm&460*660mm&460*720mm/16 | gas | 380V | 3.3KW |

BK-D32E | 400*600mm&460*660mm&460*720mm/32 | electric | 380V | 54KW |

BK-D32D | 400*600mm&460*660mm&460*720mm/32 | diesel | 380V | 3.5KW |

BK-D32G | 400*600mm&460*660mm&460*720mm/32 | gas | 380V | 3.5KW |

BK-T64E | 400*600mm&460*660mm&460*720mm/64 | electric | 380V | 72KW |

BK-T64D | 400*600mm&460*660mm&460*720mm/64 | diesel | 380V | 5KW |

BK-T64G | 400*600mm&460*660mm&460*720mm/64 | gas | 380V | 5KW |

Model | Max temperature | Dimension | N.W. |

BK-D16E | 400℃ | 1440*2290*2755mm | 1680KG |

BK-D16D | 400℃ | 1440*2290*2755mm | 1680KG |

BK-D16G | 400℃ | 1440*2290*2755mm | 1680KG |

BK-D32E | 400℃ | 1810*2270*2755mm | 1900KG |

BK-D32D | 400℃ | 1810*2270*2755mm | 1900KG |

BK-D32G | 400℃ | 1810*2270*2755mm | 1900KG |

BK-T64E | 400℃ | 2390*3150*2755mm | 2850KG |

BK-T64D | 400℃ | 2390*3150*2755mm | 2850KG |

BK-T64G | 400℃ | 2390*3150*2755mm | 2850KG |

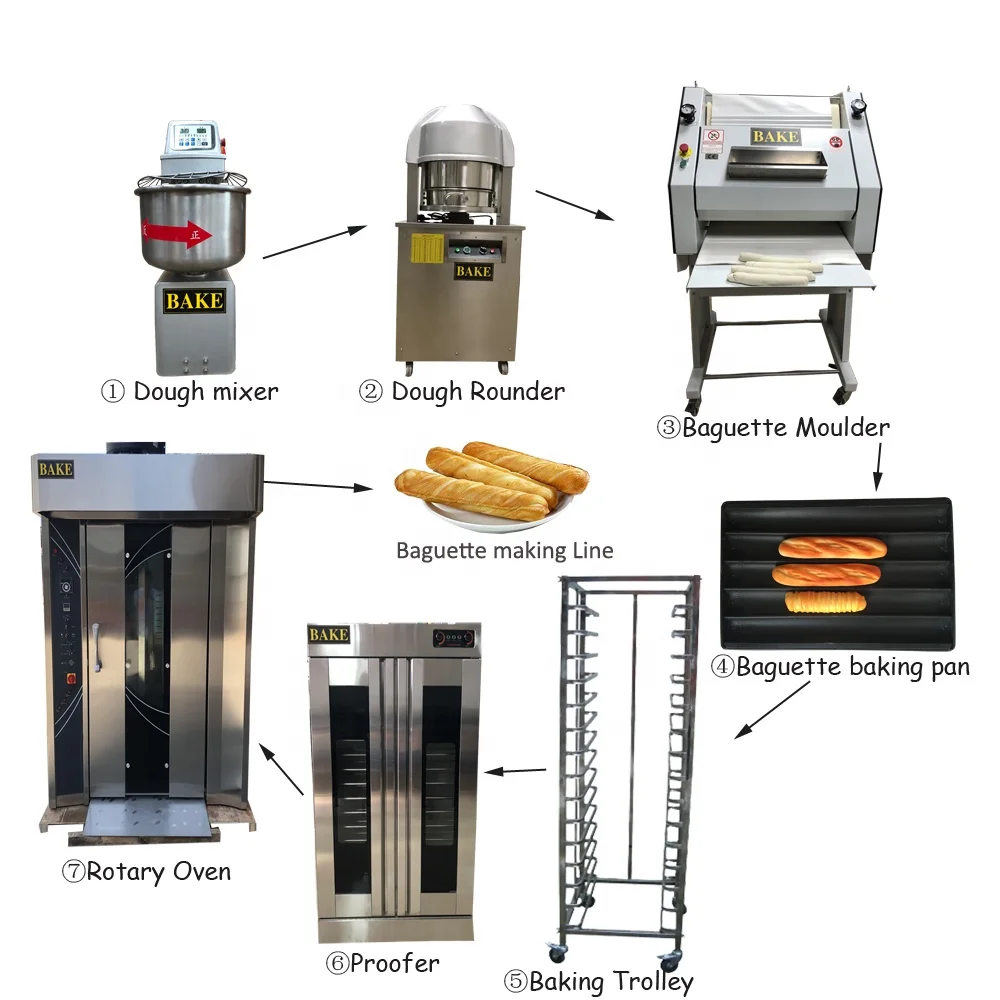

Hamburger bun bread production line ,include:

1.spiral dough mixer, for mixing dough

2.semi-automatic dough divider rounder, for dividing and rounding dough

3.hamburger baking tray,for shape and transport the dough

4.proofer, for fermentating the dough

5.rotary rack oven and rack, for baking the dough

6.hamburger slicer,for cutting the bread

1spiral dough mixer

*the motor is HAIGUANG,the bearing is NSK,the belt is GATES

*Both bowl and beater is rotary by two directions and two speeds

*The product can be controlled by manual or micro-computer

*food grade stainless steel bowl,stable and durable

*flour capacity:15kg,25kg,50kg,75kg,100kg,125kg

2semi-automatic dough divider rounder

*can divide and round 30 pieces of dough in 5-8s,6000-7000 pieces can be completed per hour

*can divide and round dough uniformly,the dough error is within 1grams

*The motor is from Taiwan HAIGUANG;The electrical parts is France SCHNEIDER

*many model,the weight range of dough is 30-100g,40-120g,80-180g etc, and it can be customized

3hamburger baking tray

with many model,also customize welcome

4proofer

*can control the temperature and steam automatically

*large fermenting number,the rack can go in and out freely,convenient and save labor

*adopt hot blast air circulation system,make the dough evenly fermenting

*the tube in the proofer is aluminium alloy and detachable

5rotary rack oven

*the front material of the oven is stainless steel 304;the other side material is stainless steel201. the thickness is 1.2mm.

*the oven can use various size of tray,the tray size can be 400*600mm, 460*660mm, 460*720mm etc.

*with slow wind and fast wind,can set the wind as your needs

*the thickness of the insulation layer is more than 150mm

*the burner is Olympia,which is imported from Japan.

*the AC contactor,thermal relay and intermediate relay all adopt France Schneider.

*with timing alarm function,Lighting control system and malfunction detection system.can detect the abnormal condition for the oven quickly.

6hamburger slicer

*two type: one is Full cut 3pcs/time,4000Pcs per hour;the other is Half cut 2pcs/time,6000Pcs per hour

*the blade is imported from Swiss,longer useful life,durable and high efficiency

*the electrical parts is France Schneider

*High-power copper wire aluminum alloy motor,durable and powerful

*Flat cutting, little scrap.Increase operating efficiency, save costs.

TWO YEARS WARRANTY

1.Our engineer can serve you a fully installed and operational line.

2. There is the basic instruction of the mechanical failure and the method how to solve it in the usage instruction clearly.I will provide you lots of spare parts free.

3.( This is only for the electric oven )

We make guarantee to free service within a year after selling. It is our responsibility to solve the problem when the machines have problem by itself, not by the artificialness. We try our best to solve it by phone, if failed, and then our technical engineer can come to your country, but you should pay for their travelling expenses, and we pay for their salary.

1, mechanical surface coated with preservative solution (to protect stainless steel)

2, the plastic cushion packing machine (prevent bump)

3, plastic film packaging (to prevent ventilation)

4, wooden case/frame packaging (easy to transport)

5, tie the bandage outside of the wooden case (reinforcement overall)

Bake Machine can be your reliable long term-partner, most professional, and most trust worthy:

1. Complete and professional range of products; one-stop purchasing for various production lines;

2. Richest experience provide you most useful service and guidance for your bakery.

3. Various connections make us satisfy all needs for customers;

4. Customized products to meet your special requirements;

5. Two years quality guarantee; lifetime technique supports and accessories providing.

Похожие товары

Автоматическая упаковочная машина для готовых пакетов хлеба // Хлеборезка/сэндвич вакуумная упаковка с многофункциональным дизайном

Завод в Гуанчжоу профессиональная изготовленная на заказ коммерческая пекарная печь из нержавеющей стали с 30 проницаемыми духовыми панелями

2023 Роти промышленная машина для Круассанов

2020 коммерческая Хлебопекарная машина для кухни

Дешевая цена распродажа ручная работа 36 шт/партия тестоделитель машина штук Ручной Гидравлический Тестоделитель для выпечки хлеба

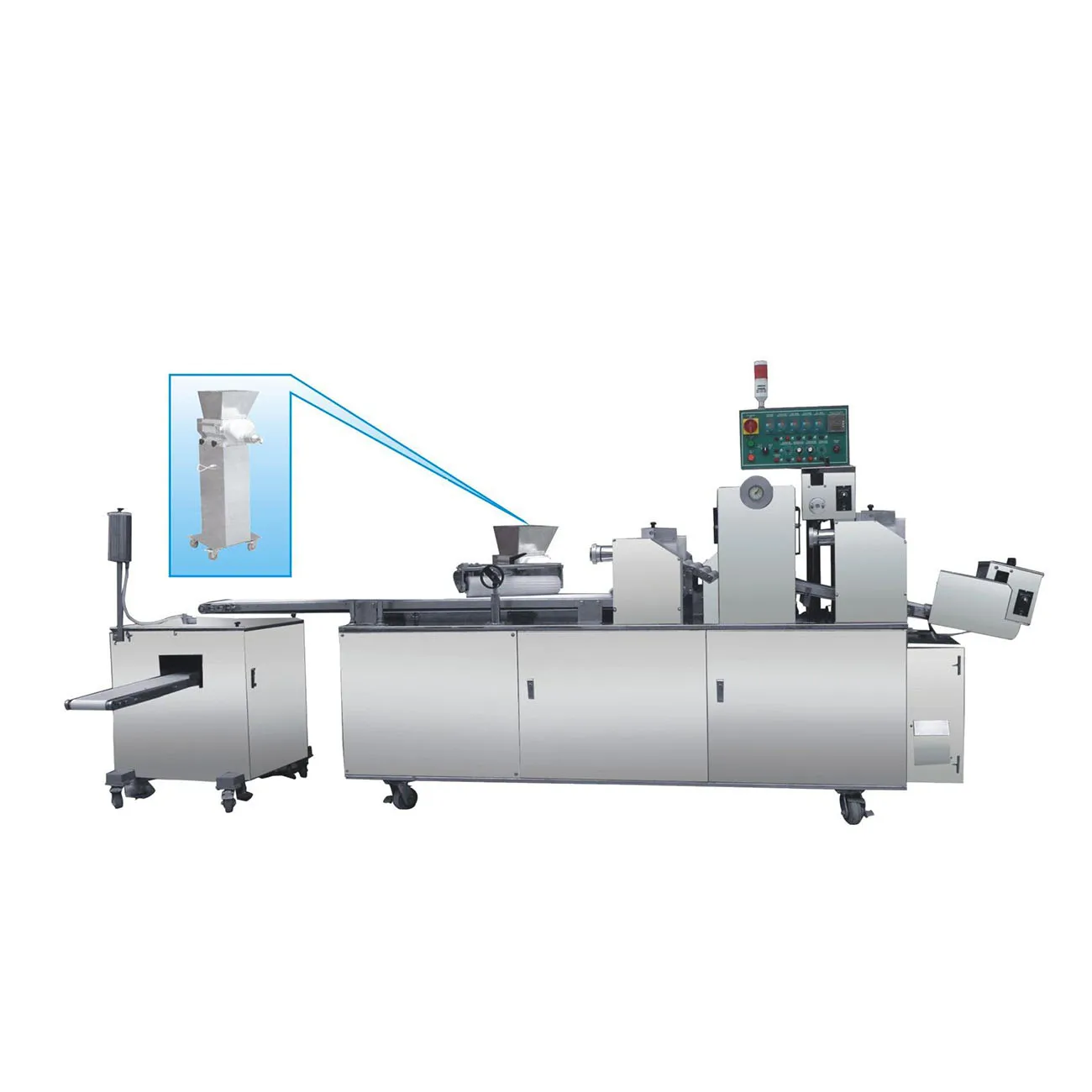

BAKEPRO ZXJ-2000B автоматическая линия по производству хлебобулочных изделий французский ручной круассан раскатка теста

Yl-32d hl-320 32 лотка 60x80 Цена горелка riello Двойная ротационная стойка для отелей

Новые поступления

Новинки товаров от производителей по оптовым ценам