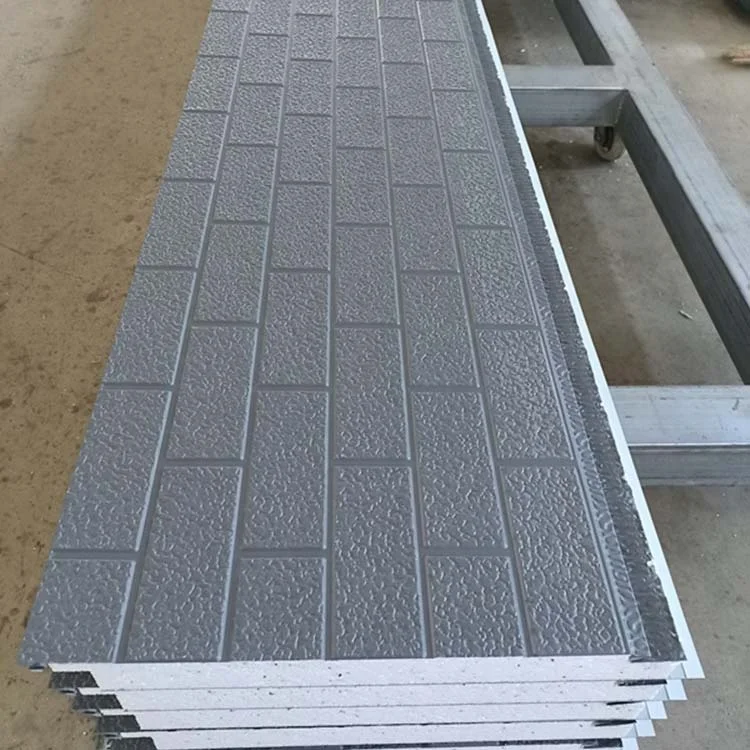

Производство FRP XPS/PU/PP/фанерная композитная панель для сухого грузового тела

- Категория: >>>

- Поставщик: Yangzhou Wansheng Industry Co. Ltd.

Сохранить в закладки 62090949952:

Описание и отзывы

Характеристики

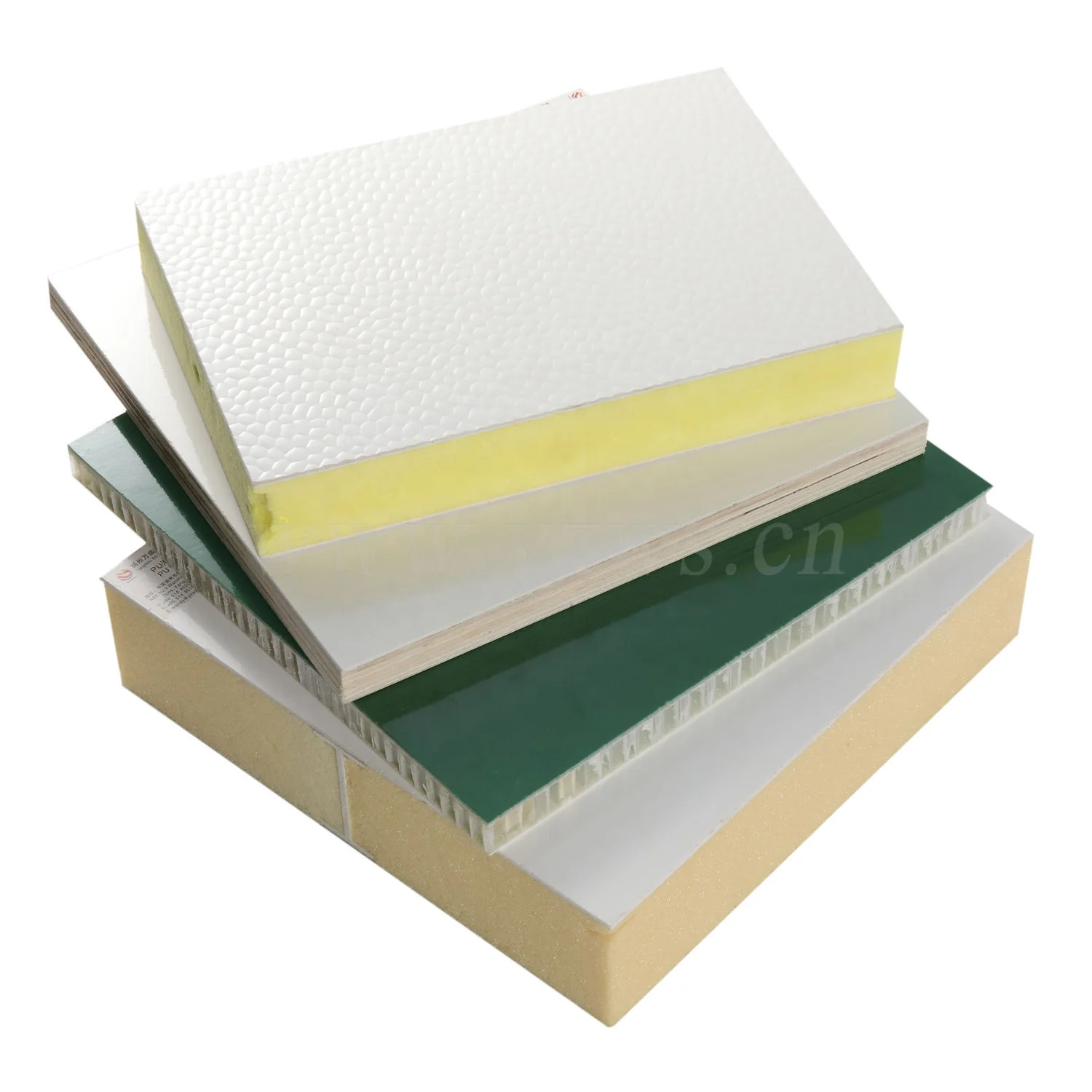

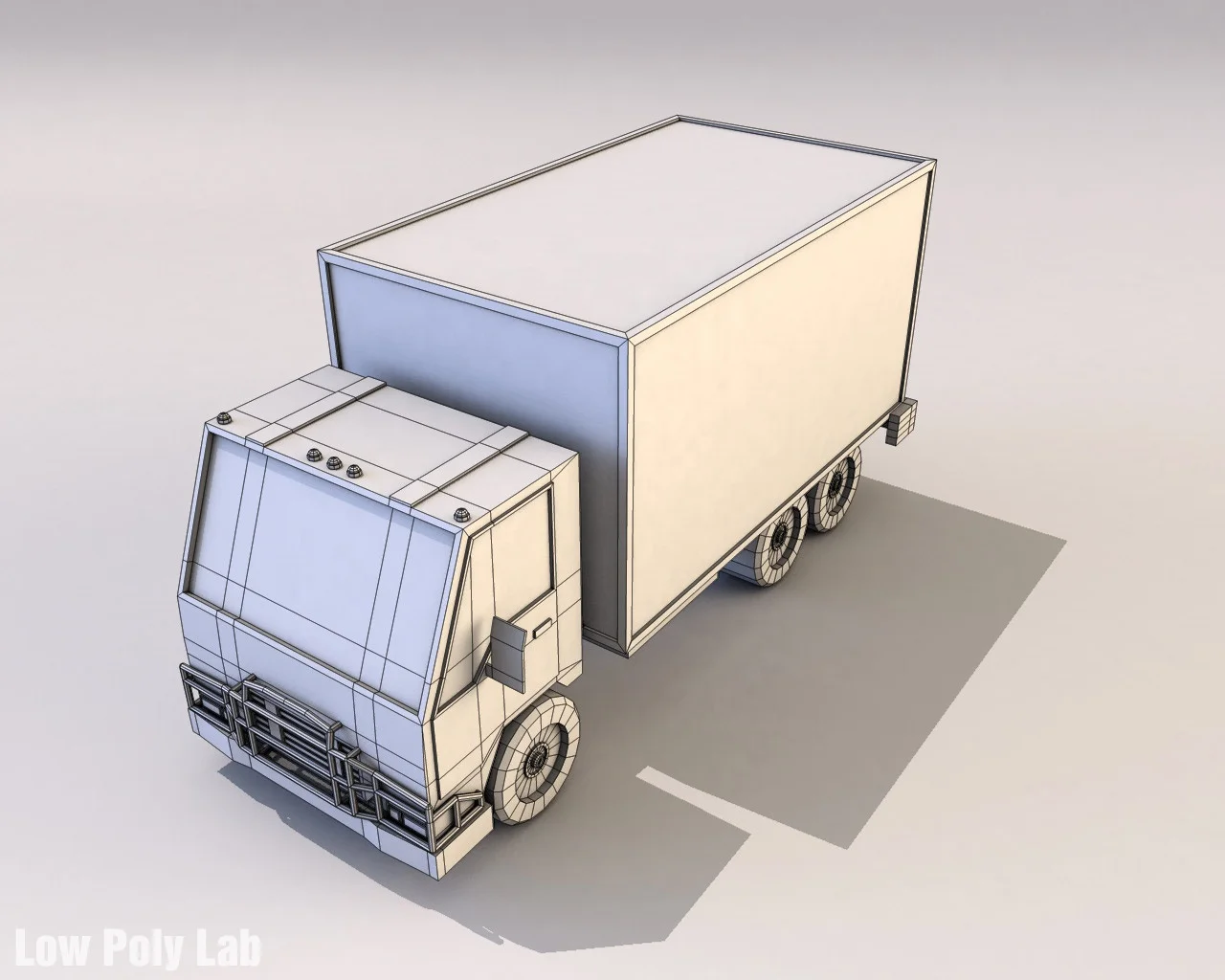

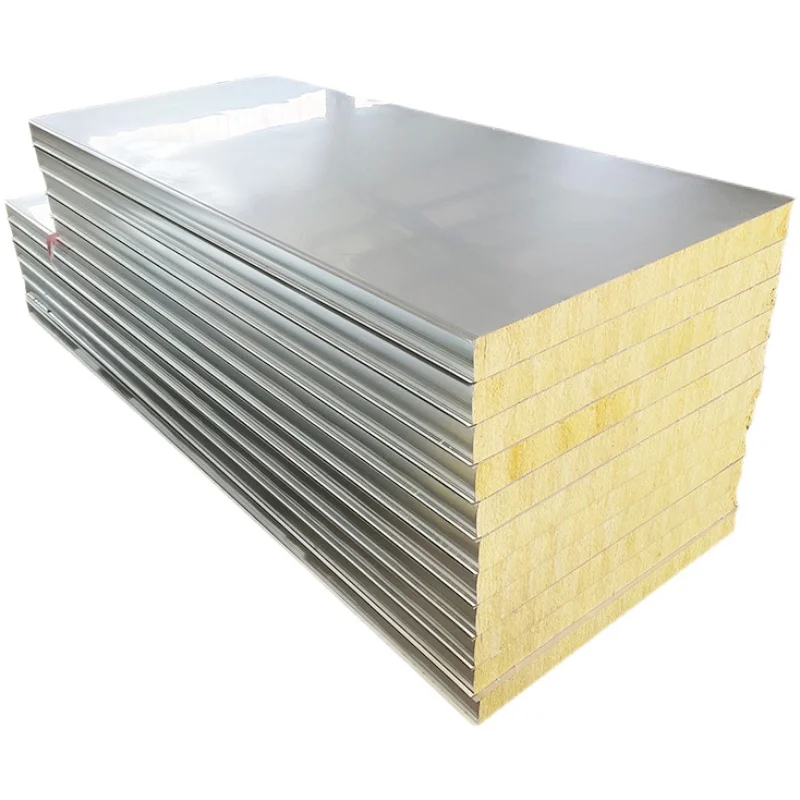

A series composite panels for RV , truck bodies and refrigerated vehicles.

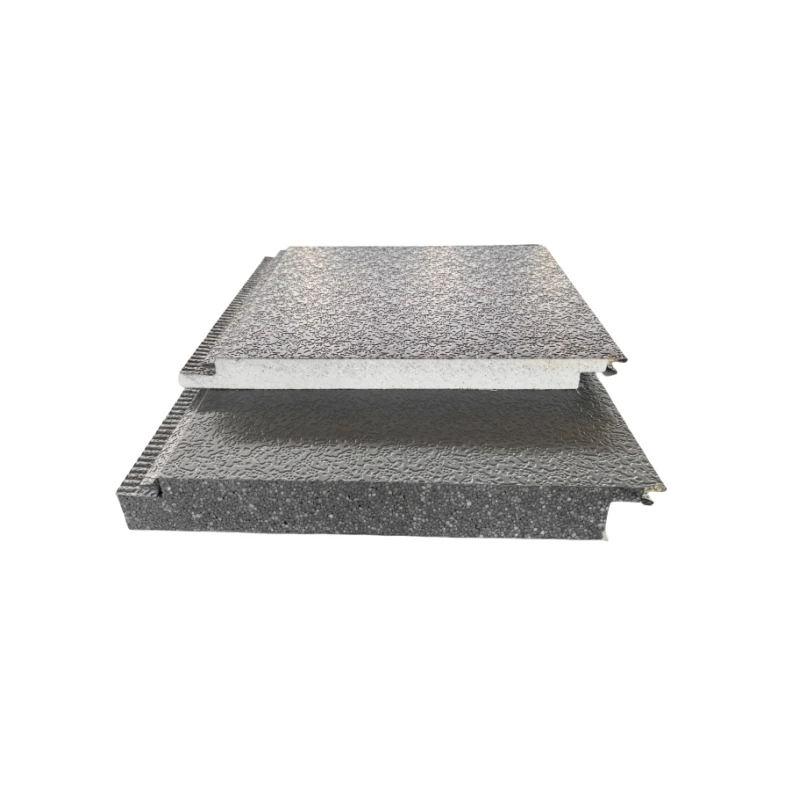

The comoposite panels made have good performance in insulation, attractive surface flatness,light weight,high strength, etc.

Specifications: Composite panels for RV:can be 2800mm wide, 9500mm long and 100mm thick at maxi- mum.Composite panels for refrigerated trucks:can be 3200mm wide,16500mm long at maximum.Thickness ranges from 30mm to 200mm. Composite panels for dry trucks: can be 3200mm wide, 16500mm long and 60mm at maximum.

Applications: Mainly used in RV,logistic boxes,refrigerated vehicles, etc

The comoposite panels made have good performance in insulation, attractive surface flatness,light weight,high strength, etc.

Specifications: Composite panels for RV:can be 2800mm wide, 9500mm long and 100mm thick at maxi- mum.Composite panels for refrigerated trucks:can be 3200mm wide,16500mm long at maximum.Thickness ranges from 30mm to 200mm. Composite panels for dry trucks: can be 3200mm wide, 16500mm long and 60mm at maximum.

Applications: Mainly used in RV,logistic boxes,refrigerated vehicles, etc

FRP Composite Panels Type

Item | FRP PU composite panel |

Core Material | PU Foam,Polyurethane Foam |

FRP skin | 1.0-3.0MM |

Core | 10-150MM |

Witdth | Max 3200MM |

Length | Max 16500MM |

Color | White/colored |

Thickness (mm) | Weight(kg/㎡) |

30 | 10.5 |

45 | 11 |

70 | 12.5 |

105 | 13.5 |

130 | 15 |

Main Performance data | ||||||

No | Item | Test results | Test method | |||

1 | Flat compressive strength | ≥0.18MPa | GB/T1453 | |||

2 | Edgewise compressive strength | ≥2.0MPa | GB/T1454 | |||

3 | Tensile strength | ≥0.85MPa | GB/T1452 | |||

4 | Barcol hardness | ≥42 | GB/T3854 | |||

5 | Thermal conductivity | ≤0.025W/m.k | GB/T10295 | |||

Note:FRP I beam is used in panels for tensile strength test while no I beams in panels in compressive strength tests.Test conditions of termal conductivity:25℃ average temperature and 15℃ temperature difference. | ||||||

Item | FRP XPS composite panel |

Core Material | XPS foam,Extrude Polystyrene |

FRP skin | 1.0-3.0MM |

Core | 10-150MM |

Witdth | Max 3200MM |

Length | Max 16500MM |

Color | White/colored |

Thickness (mm) | Weight(kg/㎡) |

50 | 8.35 |

60 | 8.7 |

70 | 9.05 |

80 | 9.4 |

Main Performance data | ||||||

No | Item | Test results | Test method | |||

1 | Flat compressive strength | ≥0.25MPa | GB/T1453 | |||

2 | Edgewise compressive strength | ≥2.0MPa | GB/T1454 | |||

3 | Tensile strength | ≥0.75MPa | GB/T1452 | |||

4 | Barcol hardness | ≥42 | GB/T3854 | |||

5 | Thermal conductivity | ≤0.03W/m.k | GB/T10295 | |||

Item | FRP PP composite panel |

Core Material | PP Honeycomb |

FRP skin | 1.0-3.0MM |

Core | 10-100MM |

Witdth | Max 3200MM |

Length | Max 16500MM |

Color | White/colored |

Thickness (mm) | Weight(kg/㎡) |

15 | 7.5 |

18 | 8 |

21 | 8.5 |

Main Performance data | ||||||

No | Item | Test results | Test method | |||

1 | Static strength | ≥25MPa | GB/T17657 | |||

2 | Elastic modulus | ≥2000MPa | ||||

3 | Flat compressive strength | ≥1.2MPa | GB/T1453 | |||

4 | Edgewise compressive strength | ≥10.5MPa | GB/T1454 | |||

5 | Tensile strength | ≥0.5MPa | GB/T1452 | |||

6 | Barcol hardness | ≥42 | GB/T3854 | |||

Item | FRP Plywood composite panel |

Core Material | Plywood |

FRP skin | 1.0-3.0MM |

Core | 10-100MM |

Witdth | Max 3200MM |

Length | Max 16500MM |

Color | White/colored |

Thickness (mm) | Weight(kg/㎡) |

15 | 12 |

18 | 14 |

21 | 16 |

Main Performance data | ||||||||

No | Item | Test results | Test method | |||||

1 | Static strength | Along wood grain | ≥60MPa | GB/T17657 | ||||

Cross wood grain | ≥50MPa | |||||||

2 | Elastic modulus | Along wood grain | ≥6000MPa | |||||

Cross wood grain | ≥4800MPa | |||||||

3 | Edgewise compressive strength | ≥35MPa | GB/T1454 | |||||

4 | Flat tension strength | ≥1.2MPa | GB/T1452 | |||||

5 | Barcol hardness | ≥42 | GB/T3854 | |||||

6 | Water boiling Test | No delamination in 72-hour water boiling | GB/T17567 | |||||

FRP CFRT Panles Type

CFRT | |

Item | Continuous Fiber Reinforced Thermoplastic Composites |

Core Material | Honeycomb PP |

Fiber skin | Mat/Woven |

Core | 10-100MM |

Witdth | Customized |

Length | Customized |

Color | White/Black/colored |

Standard values of Honeycomb panel | ||||||

Item | Unit | Standard values | ||||

weight per square metre | Kg/㎡ | ≥3.5 | ||||

thickness | mm | 17 | ||||

positive stripping | N | ≥145 | ||||

opposite stripping | ≥145 | |||||

bending strength0°/90° | MPa | ≥20 | ||||

flexural modulus0°/90° | MPa | ≥10000 | ||||

compression strength | MPa | ≥2.1 | ||||

Applications

Shelter

Caravan

Camper

Ambulance

Travel trailer

Refrigerator truck

Dry Cargo Van

Tank Truck

Incubator

Company Profile

Our Factory

Certifications

Transport & Payment

FAQ

Q1: WHAT'S THE PAYMENT TERMS?

A 30% T/T as deposit, balanced before shippment arranged. We'll show you the photos of the productsand packages before you pay the balance. T/T L/C Westem Union acceptable...other way can be negotiated

Q2 : WHAT ABOUT YOUR DELIVERY TIME? CAN WE RECEIVE THEGOODS ON TIME?

A: Usually around 3-5 weeks after order confirmed. it also depends on the total quantity of your order.

During the production processa. we will report the production progress to you at any time.

Q3 : HOW CAN I GET A SAMPLE FROM YOU FOR QUALITY CHECKING ?

A: Kindly provide us your technical details, then we will offer sample as your specitication. another way Is

to send your samples to us, we will make a counter sample for you within one week .

Q4 : DO YOU SUPPORT CUSTOMIZED PRODUCTS?

A: Yes, if you want to buy the product without any idea, we could recommend you some products according to your application, if you have your own idea, tell us, any thought acceptable, we'll try our best.

Q5 : HOW DO YOU MAKE OUR BUSINESS LONG-TERM AND GOOD RELATIONSHIP?

A: We keep good quality and competitive price to ensure our customers benefit, We respect every customer as our friend and sincerely do business and make friends with them, no matter where they come from.

A 30% T/T as deposit, balanced before shippment arranged. We'll show you the photos of the productsand packages before you pay the balance. T/T L/C Westem Union acceptable...other way can be negotiated

Q2 : WHAT ABOUT YOUR DELIVERY TIME? CAN WE RECEIVE THEGOODS ON TIME?

A: Usually around 3-5 weeks after order confirmed. it also depends on the total quantity of your order.

During the production processa. we will report the production progress to you at any time.

Q3 : HOW CAN I GET A SAMPLE FROM YOU FOR QUALITY CHECKING ?

A: Kindly provide us your technical details, then we will offer sample as your specitication. another way Is

to send your samples to us, we will make a counter sample for you within one week .

Q4 : DO YOU SUPPORT CUSTOMIZED PRODUCTS?

A: Yes, if you want to buy the product without any idea, we could recommend you some products according to your application, if you have your own idea, tell us, any thought acceptable, we'll try our best.

Q5 : HOW DO YOU MAKE OUR BUSINESS LONG-TERM AND GOOD RELATIONSHIP?

A: We keep good quality and competitive price to ensure our customers benefit, We respect every customer as our friend and sincerely do business and make friends with them, no matter where they come from.

Похожие товары

Наружная внешняя сборная настенная сэндвич-панель pu теплица pu сэндвич-панель

498,81 ₽ - 563,87 ₽

Горячая Распродажа теплоизоляционная стеновая наружная изоляционная доска для здания Pu сэндвич-доска стеновая панель стеновая наружная панель

585,56 ₽ - 650,62 ₽

Композитная изоляционная панель для холодильной панели

1 030,15 ₽

Наружные настенные панели, теплоизоляционная декоративная интегрированная сэндвич-доска, сэндвич-панейс

158,32 ₽

Образец pir pu пена изоляционная панель панели сэндвич pur

EPS сэндвич-панель EPS пена сэндвич-панель уличная теплоизоляционная декоративные стеновые панели для мобильного сборного дома

715,68 ₽ - 1 160,27 ₽

Заводская цена/полиуретан/огнезащитный/сэндвич-доска/холодильная камера, настенная изоляция

1 073,52 ₽ - 1 301,24 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $