Сверхпрочная пластиковая алюминиевая Точная миниатюрная линейная направляющая с двумя лазерными головками

- Категория: >>>

- Поставщик: Dongguan Spt Laser Technology Co. Ltd.

Сохранить в закладки 62104389984:

Описание и отзывы

Характеристики

Heavy Duty Plastic Aluminum Precision Miniature Linear Guide Rail With Two Laser Head

Employed by HG series linear slide rail for four row type, single arc tooth type contact linear slide rail, and integration of the optimum structure design precision linear slide rail overweight loads, relative to other linear slide rail promoted load and rigid ability; Have four direction of features, and automatic adjust load of heart function, can absorb the installation, a precision assembly error of appeal. High speed, high load, high rigidity with precision turn concept has become the future development trend of industrial products around the world, HIWIN four circumferenially overweight load linear slide rail based on this concept, namely, development of the product.

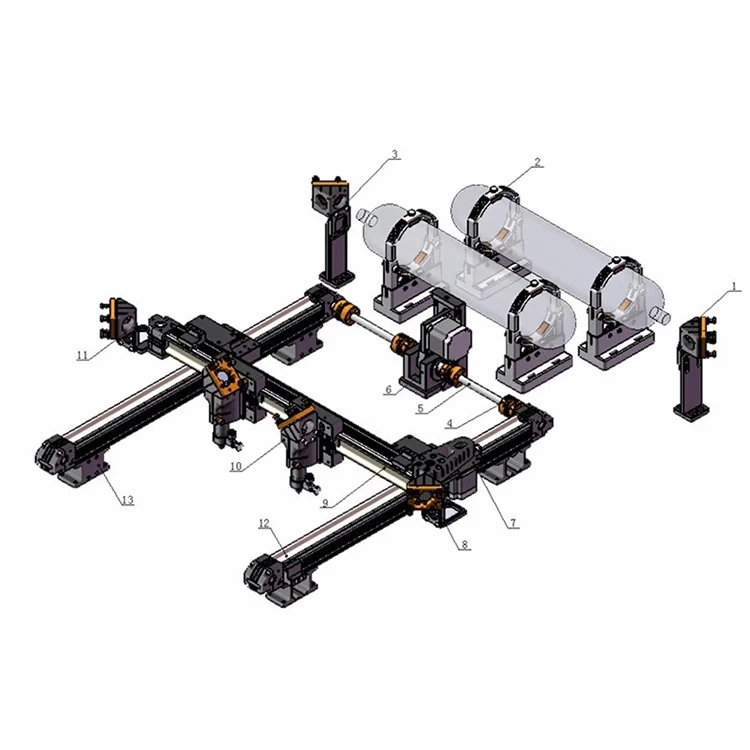

Part List(single head)

Part List(single head)

| Number | Part name | Quantity |

| 1 | Laser tube mounts | 2pcs |

| 2 | first reflective mirror assembly(left) | 1 set |

| 3 | Coupling | 2pcs or 4pcs |

| 4 | Y- transmission shaft | 1pcs or 2pcs |

| 5 | Y direction transmission assembly | 1 set |

| 6 | X direction transmission assembly | 1 set |

| 7 | X direction guide rail frame assembly | 1 set |

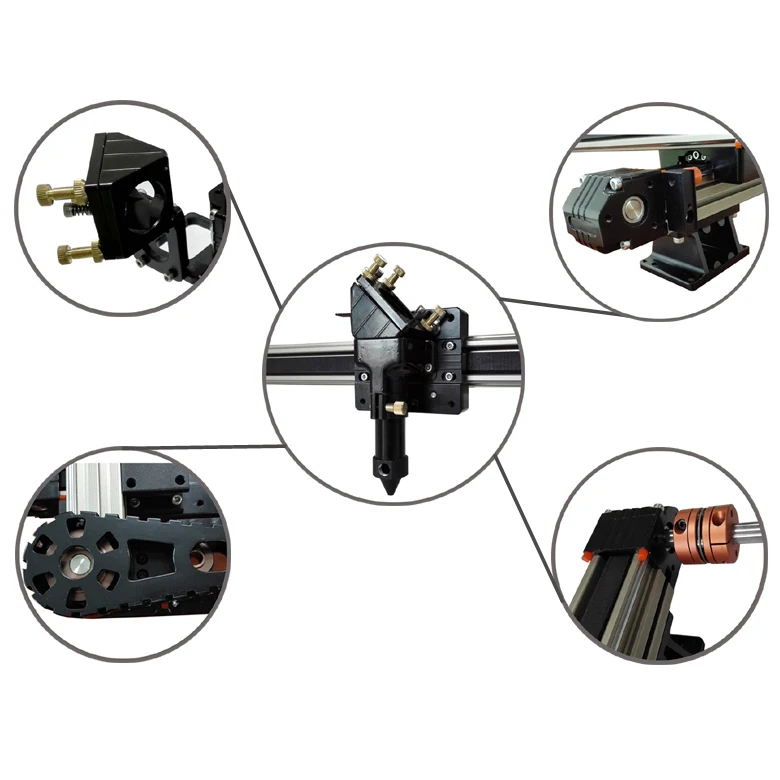

| 8 | Laser cutting head assembly | 1 set |

| 9 | The second reflective mirror assembly(left) | 1 set |

| 10 | Y direction guide rail frame assembly | 2 sets |

| 11 | Supporting base | 4pcs |

Part List(double head)

| Number | Part name | Quantity |

| 1 | The first reflective mirror assembly(right) | 1 set |

| 2 | Laser tube mounts | 4pcs |

| 3 | The first reflective mirror assembly(left) | 1 set |

| 4 | Coupling | 2 sets or 4 sets |

| 5 | Y- transmission shaft | 1pcs or 2pcs |

| 6 | Y direction transmission assembly | 1 set |

| 7 | X direction transmission assembly | 1 set |

| 8 | The second reflective mirror assembly(right) | 1 set |

| 9 | X direction guide rail frame assembly | 1 set |

| 10 | Laser cutting head assembly | 2 sets |

| 11 | The second reflective mirror assembly(left) | 1 set |

| 12 | Y direction guide rail frame assembly | 2 sets |

| 13 | Supporting base | 4pcs |

Specifications

| part name | Specifications |

| Laser tube mounts | Fit laser tube dia (mm): 60, 80, Adjustable height (mm): 25mm |

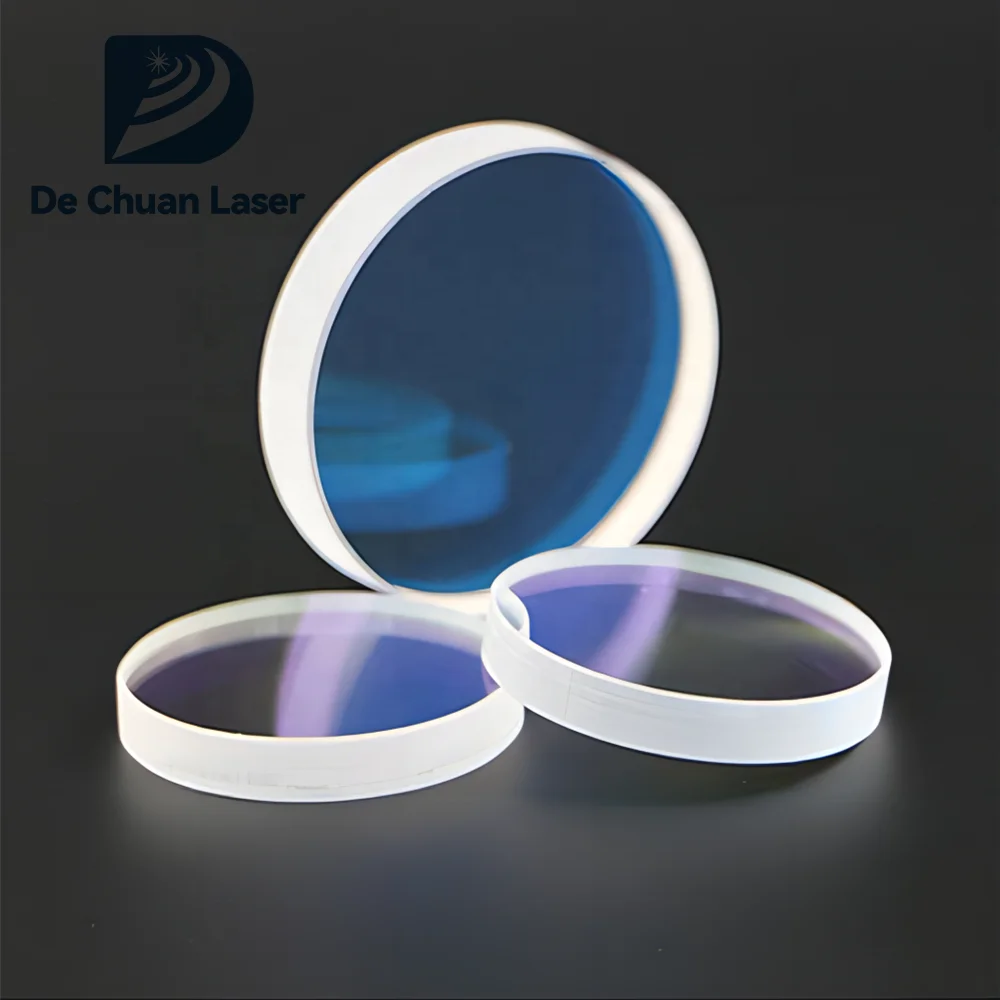

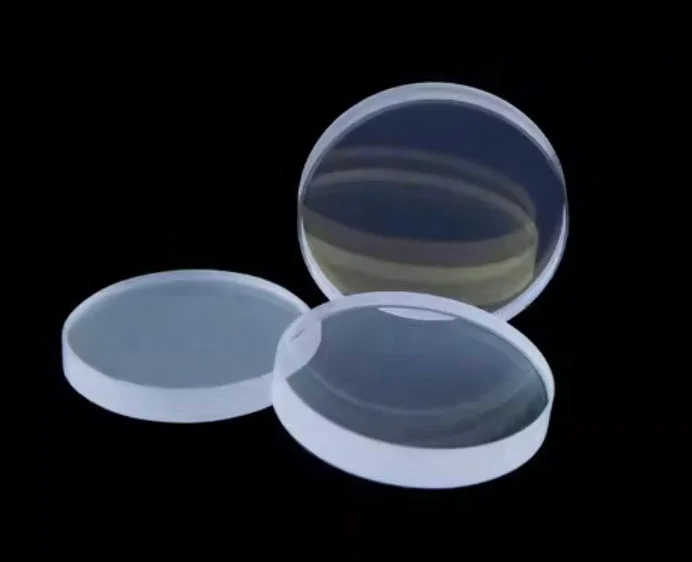

| Reflective mirror mounts | Fit mirror dia(mm): 25; mirror thickness(mm): 3 |

| Laser cutting head | Fit lens dia(mm): 20; lens focal length(mm): 50, 63.5, 75; Adjustable height of air nozzle (mm): 45 |

| X axis motor | reduction ratio, 1: 2(no motor included; size fit for Leadshine motor and Shinano motor) |

| Y axis motor | reduction ratio, 1: 2 or 1: 3 (no motor included; size fit for Leadshine motor and Shinano motor) |

| Laser beam height | The distanced between laser tube centre line to mounting surface of guide rail (mm): 164 |

| Working area | OEM (L*B);X axis≥L+390mm;Y axis≥B+285mm; |

| Module | 45# module |

| Usual working size | 400*600mm, 600*900mm, 900*1300mm, 1000*1600mm and etc |

SPT Laser technology co,.itd always committed to manufacturing stable laser core for demanding applications. Leveraging our founders'10 years experience in laser industry and deep understanding of the client's point of view, SPT has raised the standard of quality manufacturing of an entire industry in just few years.

With professional and strong R&D, manufacturing, and sales teams, SPT has a full breadth of perspective on every aspect of laser industry. Focusing on our clients demanding needs, we consistently deliver "Build to Last" laser core. As a professional supplier of CO laser core, SPT offers comprehensive solutions, incorporating technology and manufacturing customizations matching industries and applications' demands.

SPT product portfolio includes CO laser tubes, CO RF laser tubes, CO laser lenses and mirrors, laser obstacle remover and other laser devices.

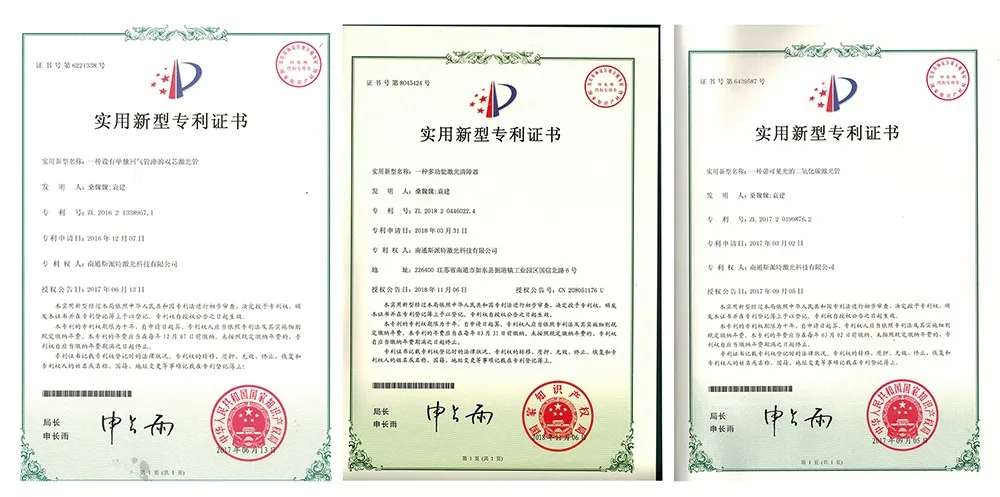

Our strict testing process and commitment to the highest international industry standards has led SPT to an un-matched manufacturing quality and highest possible product performance, certified by CNAS, CE, supported by several national technology patents. Our products are designed and tested against rigorous standards, and the entire production process is strictly managed under IS09001 quality management system and SGS.

SPT now aims to develop the most advanced and stable laser core ever conceived by balancing a culture of innovation, while striving for consistency and refined systematization of execution. We believe in growing together with our customers, providing high-quality solutions for demanding laser machinery makers and automation equipment integrators.

Our company will attend various laser and photonics exhibitions domestic and abroad every year to introduce our latest technology and products to customers. At the same time, we actively understand the latest information of the laser market and through continuous learning to create better products.

Похожие товары

Защитные линзы WSX D22.35 * T4 мм с двухсторонним покрытием, высокая прочность для волоконно-лазерной резки

Лазерные аксессуары D27.9 27,9*4,1 лазерная фокусировка режущая головка защитное окно лазерные линзы для Raytools

Объектив 20x5

Лазерные защитные окна/линзы D27.9 * 4,1 D24.9 * 1,5 D38.1 * 1,6 D37 * 7, для BT210, BT240s, BM109,BM111,BM114,BM115

Высококачественная стеклянная лазерная трубка Co2 RECI W1 T1 80 Вт 80 Вт стеклянные лазерные детали для лазерного гравера

3000 Вт робот лазерный сварочный аппарат защитные линзы волоконный лазер WSX лазерная сварочная головка защитное окно D30 * 2 1064 нм для продажи

SPT ZnSe Ge 1060 Нм лазерная Защитная ветровка для лазерной машины

Новые поступления

Новинки товаров от производителей по оптовым ценам