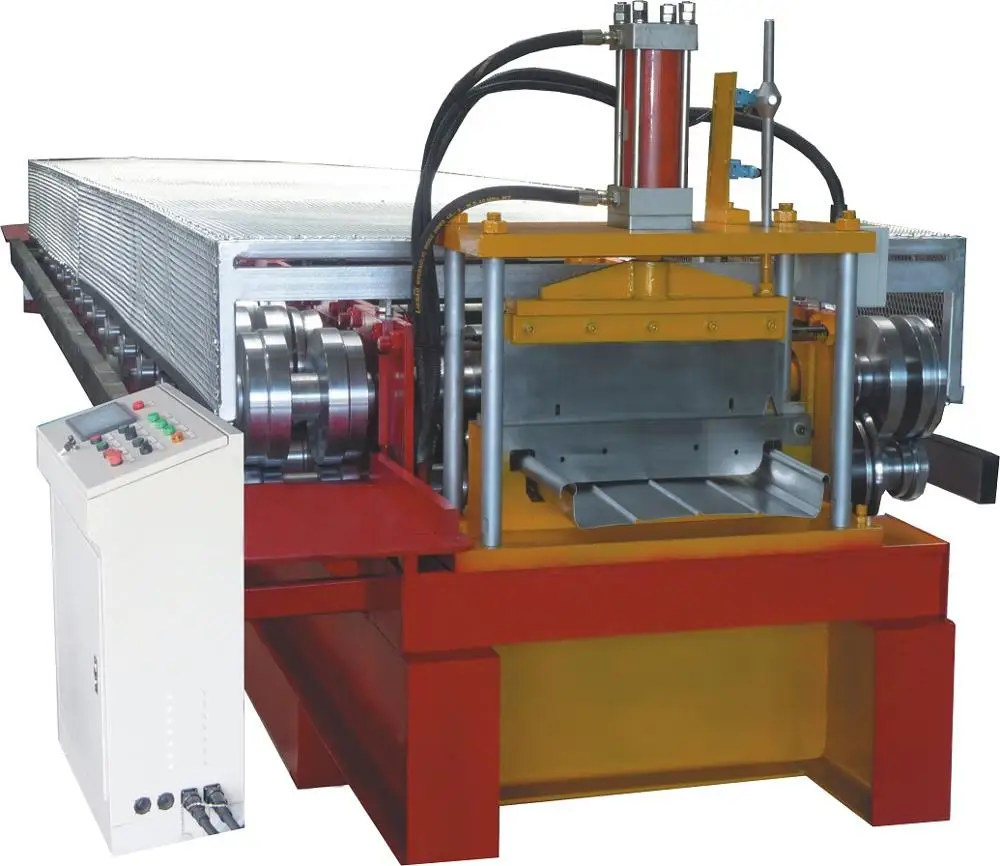

Moveable bemo стиль Турнирная Таблица шов крыши панели барабан машины

- Категория: >>>

- Поставщик: Xiamen Bogong Automatic Technology Co. Ltd.Xiamen Ltd.

Сохранить в закладки 62104783222:

Описание и отзывы

Характеристики

Dimension | 6000*1700*1600mm |

Weight | about 6500KGS |

Voltage of Motor | 380V/50HZ/3PH or depend on customer |

Main Motor Power for Running | 7.5KW*2 sets |

Hydraulic Power for Cutting | 2.2KW |

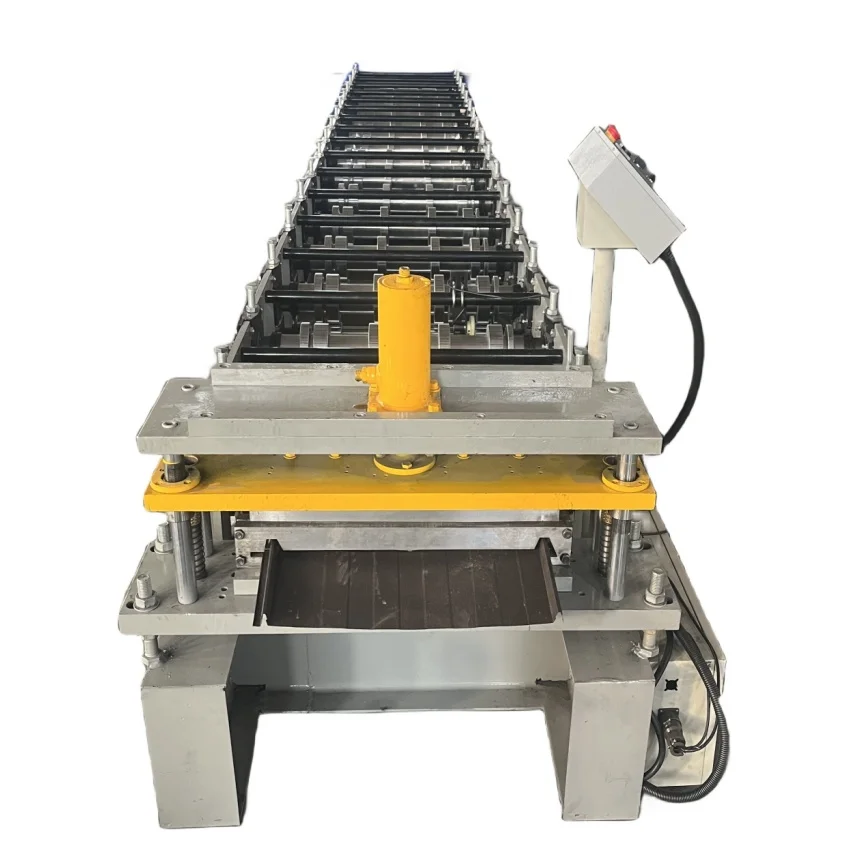

Forming Steps | 13Steps rollers |

Working Speed | 0-15m/min |

Height of Roofing | 65mm |

Effective Cover Width | 300,400mm,425mm |

Feeding Material Width | 475,575-578mm, 600-603mm |

Thickness for Al Sheet | 0.7-1.1mm |

Thickness for Steel Sheet | 0.7-1.0mm |

Min. Width of Tapered Roofing | 250mm |

Min. Length of Tapered Roofing | 1000mm |

Cutting, Forming Tolerance | ±2mm |

Roller material | 45# steel with machining----Fine Machining ---Polishing---Plated Chrome---Polishing; |

Material of shaft | High grade 45# forged steel |

Shaft Diameter | 85mm |

Main Accessories:

(1) Main Standing Seam Roof Panel Machine;

(2) 5 Tons Manual Decoiler;

(3) Hydraulic System;

(4) PLC Computer Controlling System with touch screen;

(5) Device for making taper standing seam roofing;

(6)Hydraulic Forming Cutter;

(7) Run out table;

(8)Manual Seamer;

(9) Tools;

Main Usage:

1. One machine can produce the straight standing seam roofing 300mm,400mm,500mm, and tapered standing seam roofings

2. Can automatically product variable width of roofing from 300mm to 500mm;

3.Widely use in the large project such as:railway station,airport , gymnasium etc.

4.Can product trapezoid roofing and straight roofing.

Feature: Can be packed and worked in one 20'GP or 40'GP shipping container, and , so can it saves much time, room and cost. Also can design and make the machine according to your demand.

Похожие товары

Машина для производства бесшовных водосточных желобов

ZTRFM OEM ODM машина для производства гофрированного листового металла по индивидуальному заказу металлическая кровельная гофрированной плитки

Стояющая металлическая кровельная машина

Заводская цена внешняя панель кузова грузовика формовочная машина для изготовления панелей боковых

26 калибра гофрированная оцинкованная стальная листовая металлическая черепица делая машину

Xinnuo стали катушка продольной резки китайский производитель

Автоматический гидравлический РАЗМАТЫВАТЕЛЬ с Кровельным листом формовочная машина система разматывателя

Новые поступления

Новинки товаров от производителей по оптовым ценам