MAKIT 9741 спиральная абразивная нейлоновая щетка барабан для полировки по дереву

- Категория: >>>

- Поставщик: Hefei Weixuan Wire Brushes Factory

Сохранить в закладки 62107176306:

Описание и отзывы

Характеристики

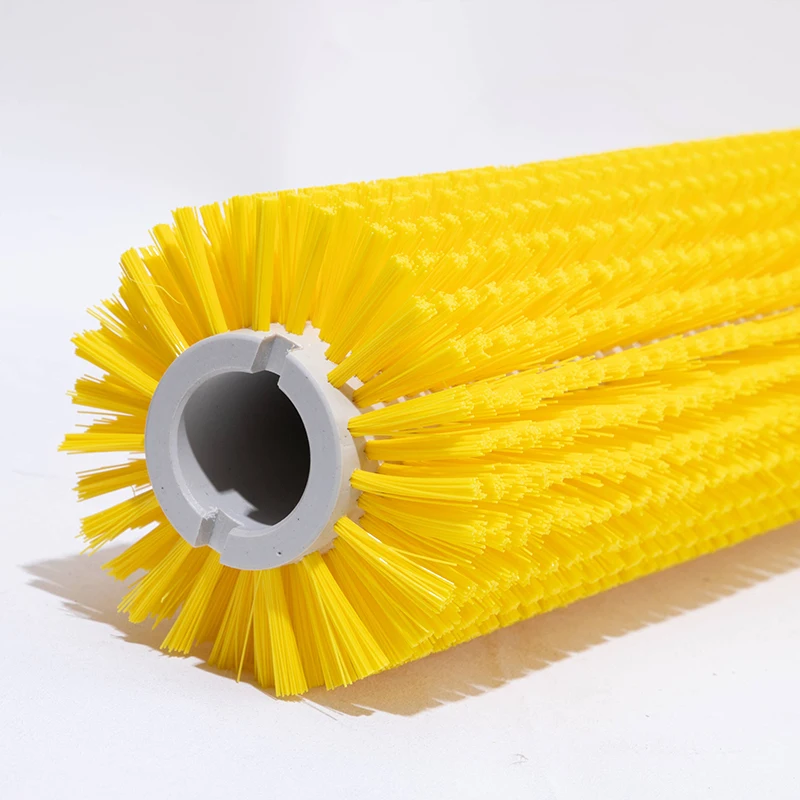

MAKIT 9741 Spiral Abrasive Nylon Wire Brush Drum for Woodworking Polish

Spirial MAKITA polimer abrasive (Nylon-abrasive)

OD:100MM

ID:36MM

Length :120mm

Filament length:26mm

Spiral base :5mm

| Grits | filament diameter |

| P46 | 1.8MM |

| P60 | 1.6MM |

| P80 | 1.2MM |

| P120 | 1.1MM |

Packing details:

Nylon Wire Brush Drum

25PCS/MASTER CATON

Dimension: 42*26*40cm

Abrasive sanding drums are an innovative product line meant to work with tools like burnishing tools, linear grinders, and contour grinders. The design of these round drums offers more surface area contact than other abrasives like sanding discs and wire wheels & brushes.

They are manufactured with a central hub featuring a ¾ inch keyed shaft to attach to a compatible tool. There are many types of sanding abrasive drums with different functions such as flap wheel drums, strip & clean drums, buffing drums, and wire brush drums.

Wire Brush Drums Construction

As mentioned above, there are many different types of sanding drums made of varying abrasive materials with different functional designs (ie. flap wheel, sanding bands, surface conditioning, etc.). The construction of a wire wheel abrasive drum consists of stiff pieces of wire extending from the center hub, similar to a wire wheel. The main difference between a wire wheel and a wire brush drum, besides compatible tools, is the extra width and surface area available on the drums.

The two main types of wire drum brushes are nylon and steel, each that offers a different structure and utility.

Nylon Brush Drums

Nylon Wire Brush Drum have course nylon bristles stretching out from the center hub. They are flexible enough to bend around raised surfaces like bolts without getting caught or damaging the drum or work surface. The nylon wires are also arranged to include void spaces between groups of bristles which allows for greater airflow that can extend the life of the wheel and avoid damaging workpieces from overheating.

What are Nylon Brush Drums Used for?

This tool is designed to be used for the following applications:

- Rust Removal

- Paint Removal

- Glue, Sealant and other Adhesive Removal

- Bondo and Body Filler Removal

- Scale and Oxidation Removal

*Specifically for surfaces with nuts, bolts, brackets or rivets, without catching edges

Steel Brush Drums

Steel wire brush drums have a more rigid construction than the nylon alternative. There are thousands of coarse steel bristles connected to the hub. Each wire is crimped to allow spacing and airflow between the wires which can keep the tool from heating up too much too quickly which would otherwise damage the tool, drum, or surface being worked on. Unlike the nylon brushes, the steel drums can catch on obstructions, so the work area should be checked before application.

What are Abrasive Steel Brush Drums Used for?

This tool is designed to be used for the following applications:

- Heavy Rust Removal

- Paint Removal

- Heavy Scale and Oxidation Removal

- Dross Removal

*Stiff bristles allow removal of rust from pits. Can apply significant pressure because the bristles are so still this allows you to really dig into the irregular surfaces

What Tools Work with Abrasive Wire Drums?

These abrasive drums are made to work with specific tools that can attach to a ¾” keyed shaft. These types of tools include:

- Burnishing Tool

- Contouring Grinder

- Finishing Tool

- Surface Conditioning Tool

- Linear Grinder

Are Abrasive Wire Drums for Wood?

The nylon abrasive drum may be used on wood surfaces. It is flexible enough to work on flat or irregular and curved wood surfaces to polish wood or remove paint. It is not recommended to use steel wire drums on wood.

Are Abrasive Wire Drums for Metal?

Both types of wire drums can be used on flat or curved metal surfaces. The steel drums can be used when you need a more aggressive grind than the nylon is capable of such as heavy scale or rust removal.

Accessories

- Various wheel brush options are available below

- 35% of customers prefer the 80 Grit Nylon Brush for the raised grain look

- 33% of customers prefer the 100 Grit Nylon Brush (standard brush, less coarse)

- 29% of customers prefer the Wire Metal Brush for metal and aggressive cleaning

Похожие товары

Высокопроизводительная нержавеющая сталь латунная проволока полировка Концевая щетка для автомобиля

OEM ODM высокопроизводительная Чистящая цилиндрическая мягкая нейлоновая полировальная промышленная роликовая щетка

Пружинная спиральная катушечная щетка для промышленного использования

Щетка для мытья стекол 5 галлонов

Индивидуальные промышленные витые двойные спиральные проволочные Дымоходные трубчатые вентиляционные щетки для очистки

3 шт. Набор щеток для дрели

Щетка для серверного шкафа втулка панель 1 RU кабель щетка

Новые поступления

Новинки товаров от производителей по оптовым ценам