Building Construction Equipment QT5 15 Automatic Concrete Block Brick Wall Making Machine Cement Machinery

- Категория: >>>

- Поставщик: Guangxi Hongfa Heavy Machinery Co. Ltd.Guangxi Ltd.

Сохранить в закладки 62111155929:

Описание и отзывы

Характеристики

Building Construction Equipment QT5-15 Automatic Concrete Block Brick Wall Making Machine machine cement block machinery

1.The main avantage of this brick machine is Super automatic block making machine in higher capacity without the filling material issue in the front row.

3.Moreover, With imported German technology, imported PLC (Siemens) PLC intelligent control component so ensure its quality.Intelligent system, all the brick making process can be programmed.

4.Compact mechanical construction guarantees finished product quality and equipment life and reduces maintenance costs.

Main Technical Specifications | |

Overall Dimension | 7400×1950×2700(mm) |

Rated pressure | 21MPa |

Main vibration form | Platform vibration |

Cycle Time | 15-20 seconds |

Vibrating Frequency | 2800-4500rolls/minute |

Motors Power | 26.5KW |

Pallet Size | 1100*550(mm) |

Raw Materials | crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes. |

Applied Products | concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc. |

| QT5-15 new automatic concrete brick machine productivity | ||||

| Item | size(mm) | Qty/mould | Cycle molding | per hour |

| hollow brick | 4000*200*200 | 5pcs | 16~20s | 1125pcs |

| porous block | 240*115*90 | 16pcs | 15~20s | 2880pcs |

| clor brick | 225*112.5*60 | 28pcs | 15~17s | 7680pcs |

A- The advantage of Molding Machine:

1- With Siemens PLC control system and Touch-operating Panel, Double Delta frequency converters, use less labor. Saving 25% energy compared to the same industry in the market.

2-Hydraulic transmission,mechanical vibration, hydraulic pressing and forming are adopted

3- Adopting the advanced forced material-feeding & distributing device, More durable.

4- The computer is of fault diagnosis system. Warning signal is propitious to eliminate the fault.

Produce kinds of bricks by changing moulds.

It could make many kinds of color-faced pavement tiles, color-faced grass-planting bricks and curb bricks, as well hollow blocks and interlocking wall bricks by changing different molds.

1. What is the brand?

Now a lot companies embezzle our brand, pls take note our prevention fake-mark.

2. Does this brand has good reputation and sell well in the market?

we got good reputation and are one of the biggest supplier in China.

3. What is the materials they used? Maganese steel or A3 steel?

We use Maganese steel which stronger than A3 steel

4. What is the lifetime of the mold?

Our mold can use 800,000 - 900,000 times

5.What is the guarantee period?

We guarantee for one year

7.The price cover what equipment?

( pls refer to our quotation list)

Q: How can you guarantee the production quality ?

A: Our production quality follow China construction machinery standard JGJ33-2012. We have 27 years experience on producing the machines and will be inspected by QC team for ach shipment. We have strictly quality control system in our production process. We have 4 times inspection for each finished product before package Third part inspection acceptable.

Hongfa Group Established in 1990.

A leader developer& Manufacturer of Construction Material Machinery.

Main business Range & Products:

Lightweight Panel Production Line, AAC Block Production Line, Full Automatic Concrete Block Production Line, Artificial Quartz Plate Production Line, Concrete Pipe Machine, Concrete Tile Machine, Concrete pipe machine, Bidirectional Hydraulic Brick Maker, Mining Machinery, Concrete Batching plant, Stereo Parking Equipment, etc.

Hongfa Strengths

More than 30 years experience. 1500 employee (50+engineers)

2) Total 4 factories with 440,000M2 and annual sell above USD100 Million .

3) 10,000 customers and fulfillment to over 120 countries.

4) Continuous service and logistics system.

5) High quality products and competitive price.We hope we can cooperate with each other and establish a win-win business relationship.

Welcome to visit our factory !

1.One of Top Ten Influential Brands in China Brick &Tile Industry

2.China National Enterprice Abiding By Contract & Keeping Good Faith

3.Quality and Credibility of the Dual-protectionb Demonstration Unit

4.High and New Technology Enterprise

5.Famous Trademark of China

6.Star Enterprise with China Patent

7.AAA Grade Credit Enterprise

8.Consumer Satisfaction Unit

9.One of Top 100 building Material Industry Brands of China

10.One of Top Ten Good Faith Units

11.Advanced Exporter in Guangxi Province

12.Advance Quality Management Unit

Hongfa supply our customer for designning, production, installation, commissioning,

training and good after-sale service.

Benefits from Hongfa Group Service:

Consecutive training courses

Machine operation Maintenance

Conrete block making technology

Practically orientated training courses

Specially designed for the building brick industry

Practical exercises with specific designed models or machinery parts

Aquired knowledge available anywhere and anytime

Optimum training and know-how transfer from the beginning

Похожие товары

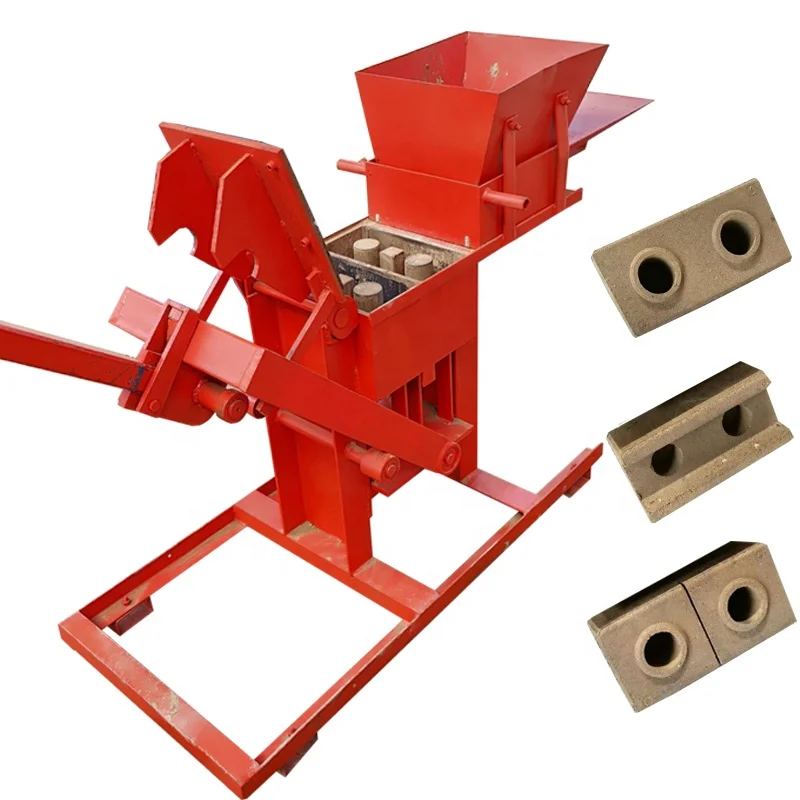

Makiga Stabilised Soil Compressed Earth Block Brick Making Machine Price in Kenya Terre Brique Geobeton

Qtj4-24 блок машины строительный материал машинный производственная линия

Горячая Распродажа Полуавтоматический гидравлический пресс для производства глины твердый грязевой кирпичной машины Ручной кирпича

2 Bricks /mold Full Auto Hby1-10 Startop Interlocking Brick Machine/machine for Clay Burning Free

Clay Interlock Block Machine Interlocking Brick Machine Making

Низкая цена QT4-25 станок для производства полых блоков

Гидравлическая машина для разделения брусчатки

Новые поступления

Новинки товаров от производителей по оптовым ценам