Import Thermal Lamination Film Process in Chinese

- Категория: >>>

- Поставщик: Xiamen Best Resource Foreign Trade Co. Ltd.Xiamen Ltd.

Сохранить в закладки 62112120420:

Описание и отзывы

Характеристики

Import Thermal Lamination Film Process in Chinese Manufacturer

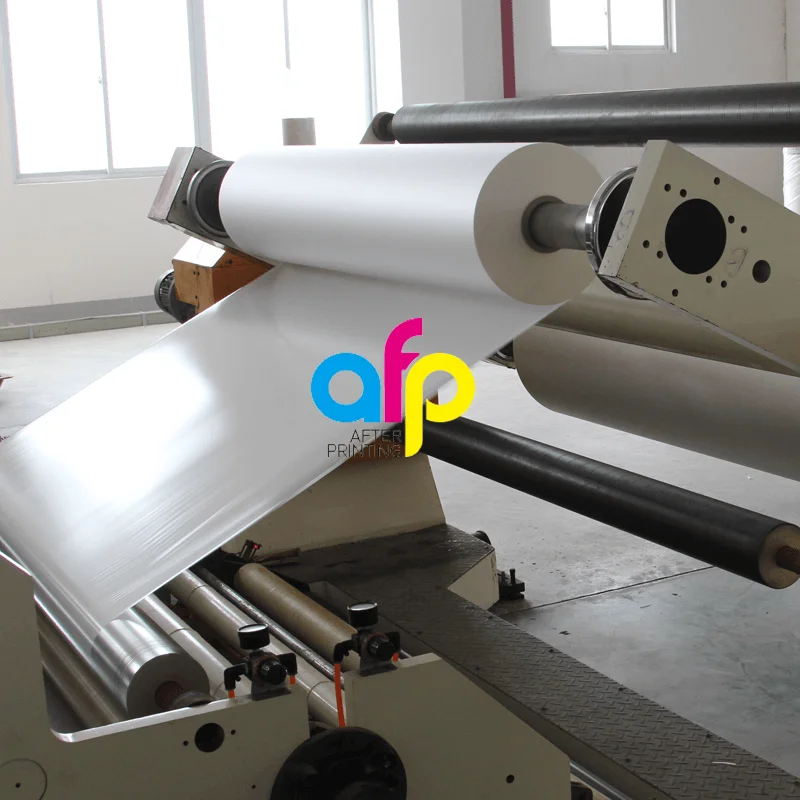

Import thermal lamination film process is used to laminate printings pursuing effect of more luster, elegant, visually comfortable sense, and comfortable touch sense.

It prevents lamination from being pressed, bubbled or desquamated.

It also protects laminated printings from harmful substances and is moisture-proof, ensuring long life storage.

Thermal lamination film is produced by multi extrusion coating lines.

It consists of two layers. One is the plastic film, of which mainly is BOPP or PET film, another layer is the adhesive glue of EVA .

Thermal Lamination Film is also called dry, hot or heat lamination film.

Compared with wet or cold lamination film, the thermal lamination film is more convenient at operation, while costing overwhelmingly less.

By sort of base film material, we are producing two types of thermal lamination film:

BOPP Thermal Lamination Film and PET Thermal Lamination Film.

By sort of surface finishing, the thermal laminating film rolls we are producing include:

Here mainly shown are product technical parameter, suitable for both glossy and matt lamination film.

| TECHNICAL DATA | |||

| Item | BOPP Thermal Lamination Film Roll ( Glossy & Matte ) | ||

| Material | BOPP + EVA | Roll Width | from 180mm to1880mm |

| Thickness | from 15micron to 30micron | Roll Length | from 300m to 6000m |

| Core Size | 1inch (25.4mm), 3inch (76mm) | Corona Treatment | Single or Double |

| Joint | ≤1 | Sur.Tension | up to 42 dynes |

| MOQ | 2 tons (or 2,000.00kgs) (mixed width 500mm,600mm,700mm etc.) | Shelf Life | 12 months |

APPLICATION GUIDANCE | |||

Compound Temperature | 85℃ ~ 110℃ (185℉ ~ 230℉) | ||

Compound Pressure | 10 ~ 18mpa | ||

Compound Speed | 10 ~ 60m/min | ||

After-printing is devoted to providing quality materials for post-press finishing supplies and plastic packaging films.

It is subject to Xiamen Best Resource Foreign Trade Co., Ltd, who itself is sharing a factory producing Thermal Lamination Film powered with five producing lines yielding 750MTs every month.

Since from 2008, we have been seeking for a role being as the most reliable supplier and partner in printing and packaging fields, resulting from stable high product quality and reputation service.

We are able to deliver a 40 feet container (approximately 24MTs) of Thermal Laminating Film within 20 days delivery lead.

Our products are now well received in North America, Latin America, Asia, the Middle East as well as Europe with CERTIFICATIONS of FDA, RoHS, REACH and EN 71-3.

To be specific at main products, After-printing serves plastic film rolls including:

Choose After-printing, choose the trust-worthy.

| Looking for more types of Lamination Films? |

|

|

|

- Used in the field of post-press, which is proceeded by a hot laminating machine. - It enhances the finished item's value through high transparency and super luster finish, which ensuring long life storage for the prints.

| - Proceeds by wet laminating machine, which can be used by the ways of both cold lamination machine and a thermal laminating machine. - The suitable adhesions are water-based glue and non-solvent based glue. - Popular thickness 10micron, 12micron, and 15micron.

|

- Used as a stationery product for protection such as photo, documents, etc. - Available in the format of sheet and roll, sheet pouch lamination film is common lamination process to make simple and smaller laminates. - Roll pouch lamination film is applied via thermal laminating machine.

|

Похожие товары

Акриловая ванна для прогулок пожилых людей прямоугольная с ограниченными возможностями компактный

Новые стильные аксессуары для занавесок металлические булавки

Женская 100% хлопковая индийская туника в этническом стиле Пляжное Платье с принтом ручной работы летнее платье длинными рукавами и пуговицами

Plywood Formwork Form Tie System B with Plastic Rod

Полностью самоходные подъемники/открытый электрический ножничный

горячей продажи популярных компьютеризированная выстегивая

Красные Взрослые Унисекс костюмы на Хэллоуин для вечеринки полных воздушных костюмов надувные пиратские

Новые поступления

Новинки товаров от производителей по оптовым ценам