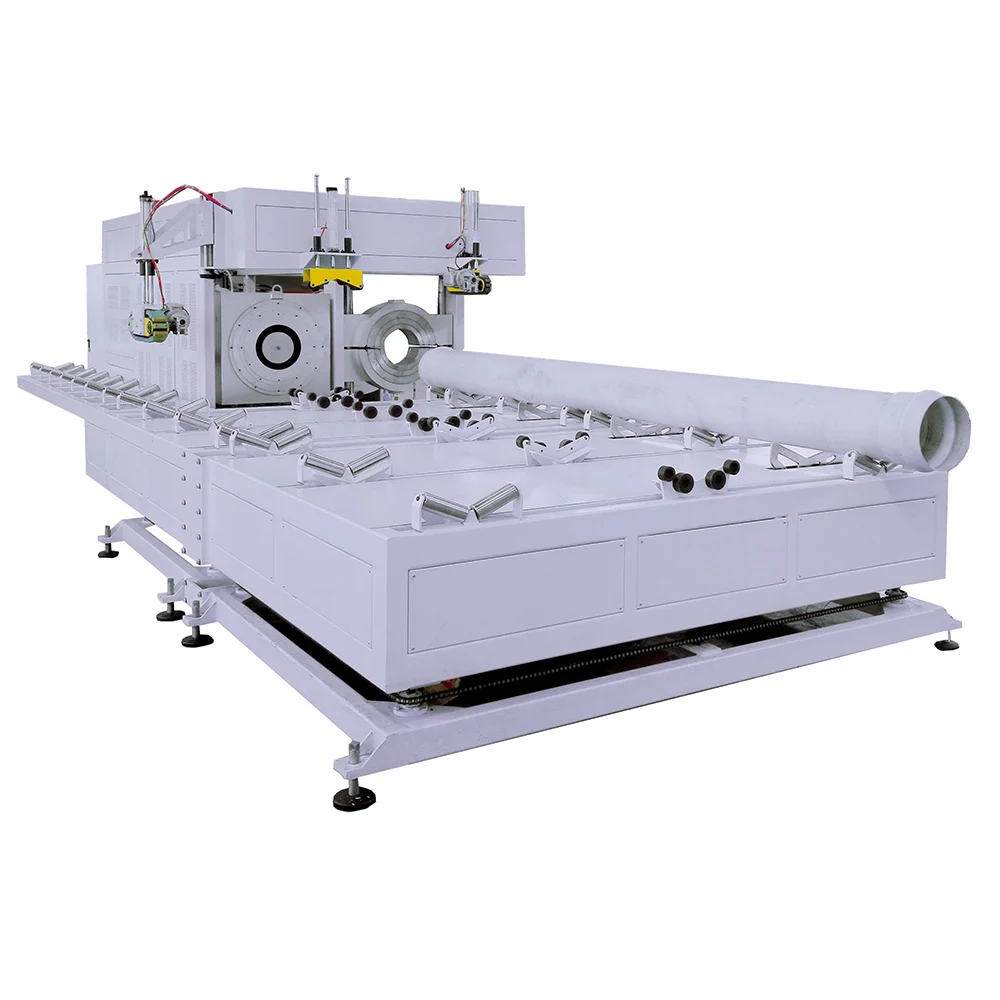

Большая двойная машина для обрезки труб из

- Категория: >>>

- Поставщик: Shenzhen HYPET Co. Ltd.

Сохранить в закладки 62121624243:

Описание и отзывы

Характеристики

large pvc pipe double oven belling machine

Condition of use:

It can be used for expanding from φ315-φ800 PVC pipes

315mm, 400mm, 500mm, 630mm 800mm

Power supply: 380V3 phase, 50Hz 45kw

Our Features:

l This machine is controlled by PLC,

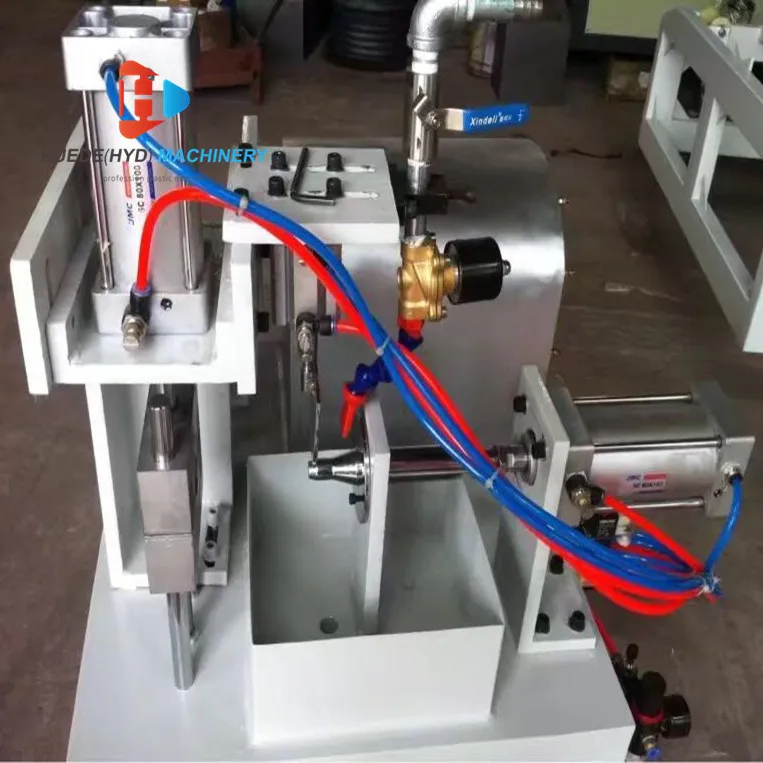

l Heating system is infra ray system and controlled by electric auto system.

l There are inner and outer heating system for the pipe to be heat even.

l The pneumatic system and hydraulic parts are imported from Japan

l The movement is steady and it may change the pressure size. It does not leak.

l The work table can be easily operated, and the machine has the scale division, which matches the pipe size.

l The electric controlling components are Simense, Fuji world famous brand parts

l Long term service would be offered after sales.

Main Specification

Scope: φ315-φ800 mm

Heating power: 38kw

Total power: 60 kw

Central height 1160 mm+/- 50mm

Thickness of the pipe: 40mm

Dimension: 8710 x 3260 x 2800 mm

Weight: 8000 kg

® Adopt Germany technology, it can achieve the highest output of China equipment;

® The inside of the barrel cast with bimetallic, screw spray alloy.

Warranty period is up to 2 years

® HYPET special feeding device, open spiral groove, large feeding quantity, easy to replace, low cost.

® HYPET gear box is high speed and high efficient with low noise, to ensure 3 years using;

® The control system can be equipped with intelligent type, to meet the customer's future custom special requirements.

Product Feature

HYMAX Extruders with following distinctive features

High output, low power, good products

Screw designing abilitity for different products

Screw and barrel material are in bi-metal type

Gear box is the first class in the world

Intelligent PLC electric control system

1. We have more than 30 years in extrusion field

2. Introduction from German tech and experience for the design and making twin screw extruders. And leaded by Germany experts Mr. Youcef and Mr. Elben for the long time

3. Designed and produced twin conical screw extruder, twin parallel screw extruder, and transfer the technology to the biggest gears factory in India

4. With high professional design team

5. A base combined with designing, making, studying in extrusion industrial.

6. Our philosophy is to learn advanced technology, make the best suitable machine, best efficient machine and best lines.

1. In 2002 the company was established.

1. In 2002 the company was established.

2. In 2004, the establishment of plastic extrusion machinery Institute to study and study the German extrusion machinery technology.

3. In 2006, developed a continuous straight cone double reducer, for the Chinese machinery to jump on a step to contribute.

4. In 2007, developed a series of flat double reducer, the smallest 65, the largest 130, to fill the gaps in the domestic, while forming a high level of flat and cone series twin screw extruder, welcomed by the market warmly.

5. In 2008, the opening of its own 10,000 square meters of large-scale mechanical plant, as Huiyi large-scale production base.

6. In 2009, developed its own twin-screw split double alloy barrel, wear-resistant, long life, has been well received by customers, and some customers can even use 7 years.

7. In 2010, focusing on the development of Pakistan, India, Kenya, Algeria, Egypt, Saudi Arabia, Brazil, the United States, Portugal and other countries of the customer network.

8. In 2012 PE / PRR pipe unit R & D success, the most advanced and efficient single screw extruder, to achieve high yield, high efficiency, low energy consumption of the best results, screw barrel bimetallic, life than the general to extend 80%.

9. In 2013, flat double extruder on the steps, PS67 / 27 parallel twin extruder 30kW motor production reached 300 kg / h 90/27 to 500kg / h, PS107 / 27 extruder to 800kg / h.

10. In 2014, cone double extruder power unchanged, yield increased by 30%, ZS65 / 132 extruder production reached 350kg / h, ZS80 / 156 extruder production reached 550kg / h

11. In 2014 sales of flat double reducer technology to India.

12. In 2015, with foreign experts to develop suitable for plastic machinery energy-saving devices, energy saving up to 25-30%, is currently applying for technical patents.

13. In 2016, the development of a new technology 630PVC large tube unit, high output, stable and reliable production, to the advanced level.

Похожие товары

Ручная машина для развальцовки пластиковых труб склеивания из ПП ПЭ

Машина для прокатки труб из ПВХ/машина для расширения пластиковых труб

Производитель, автоматическая машина для скручивания труб серии SKR для пластиковых ПВХ/PE/PP/UPVC/HDPE труб

Машина для скручивания труб из ПВХ/полностью автоматическая машина для скручивания труб из ПВХ

Машина для сверления пластиковых труб

Полностью автоматическая машина для скручивания пластиковых труб ПВХ с управлением PLC

Горячая Распродажа, машина для скручивания ПВХ труб

Новые поступления

Новинки товаров от производителей по оптовым ценам