Китайский Малый металлический сварочный Рабочий стол TIPTOP

- Категория: >>>

- Поставщик: Jiangsu Tiptop Machine Tools Co. Ltd.

Сохранить в закладки 62135023880:

Описание и отзывы

Характеристики

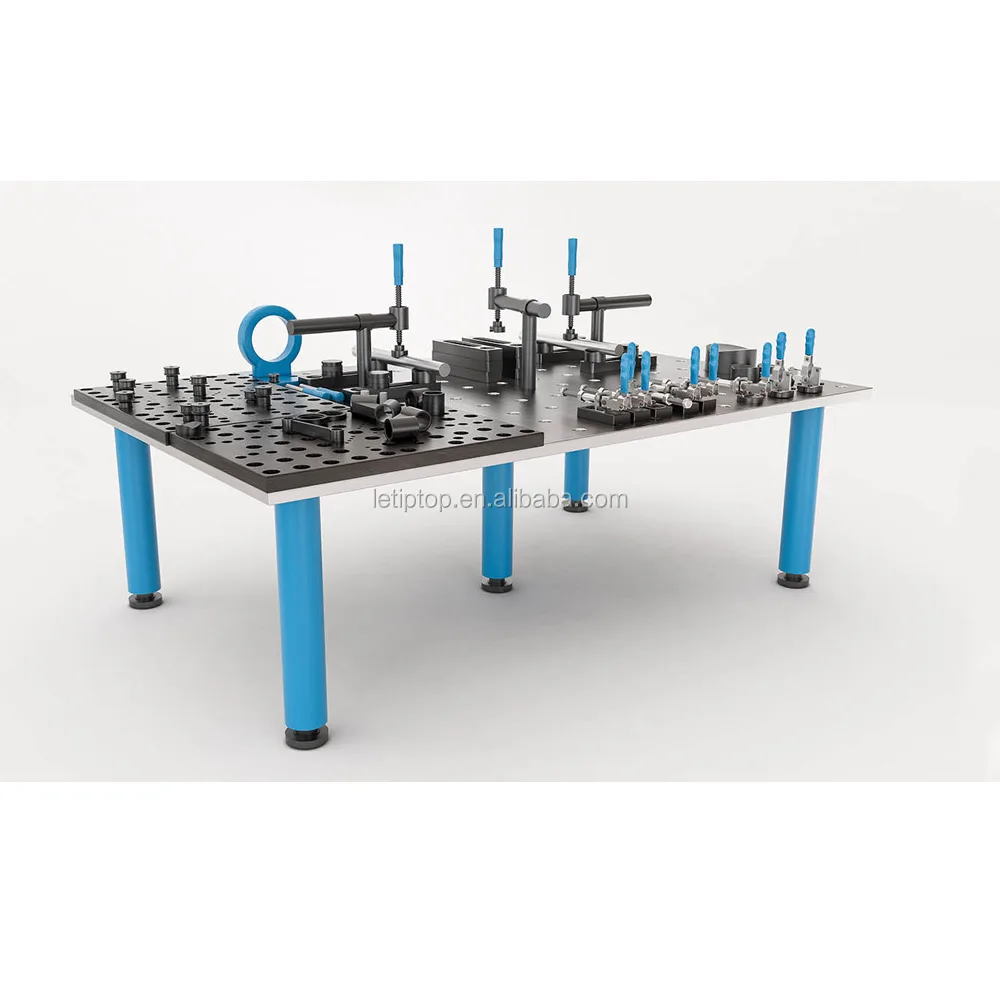

China TIPTOP Small Metal Welding Workbench Table

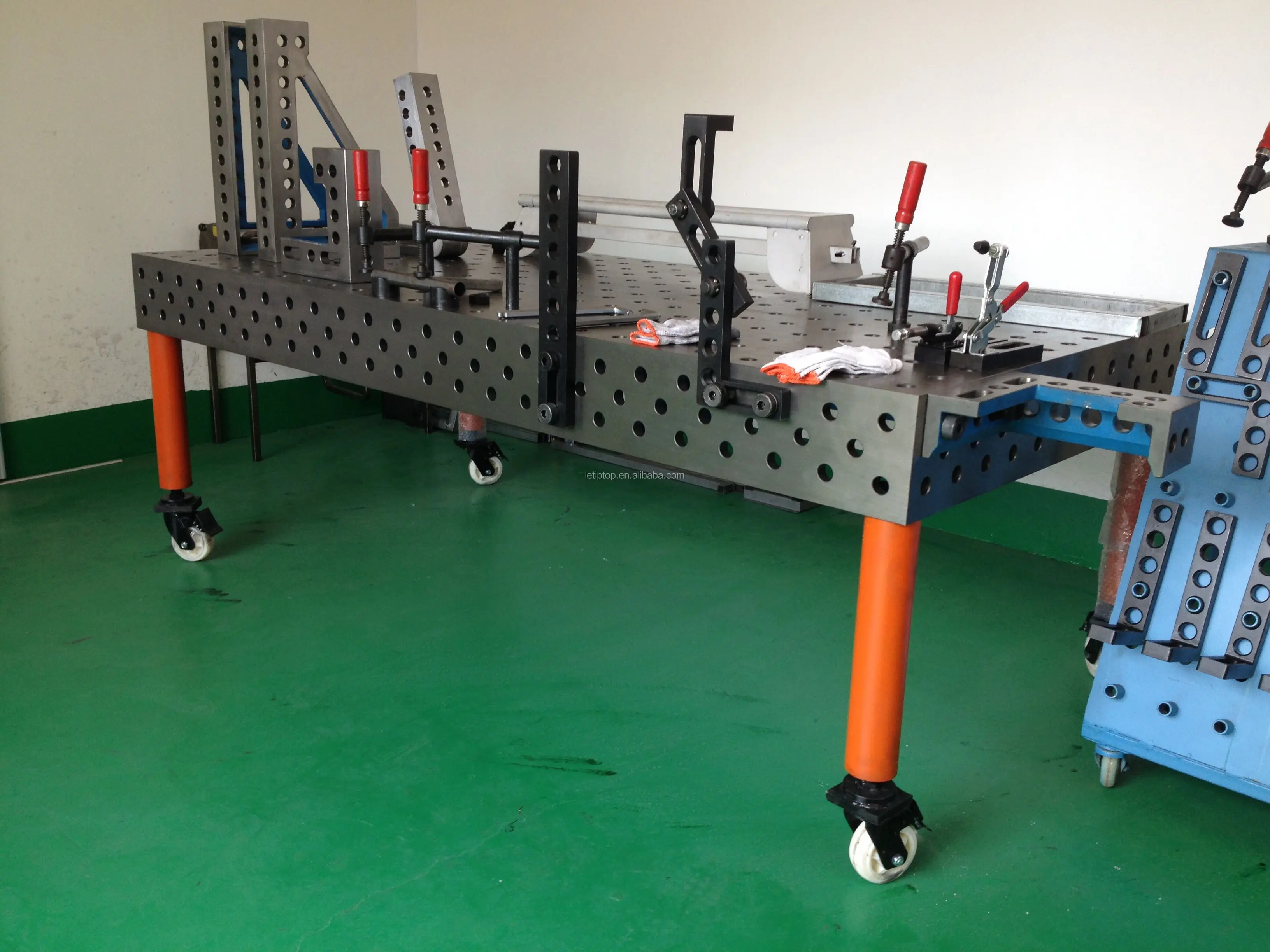

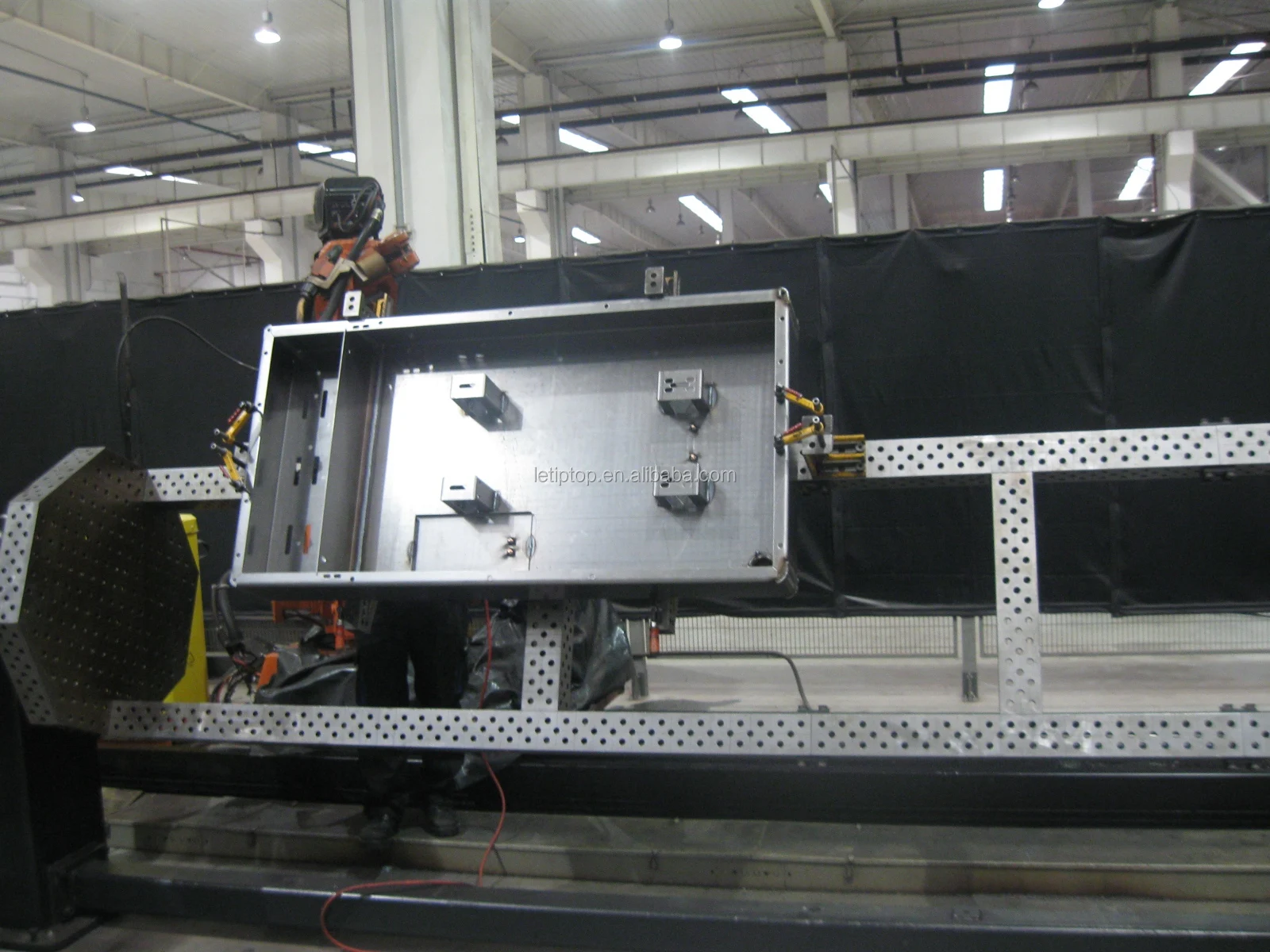

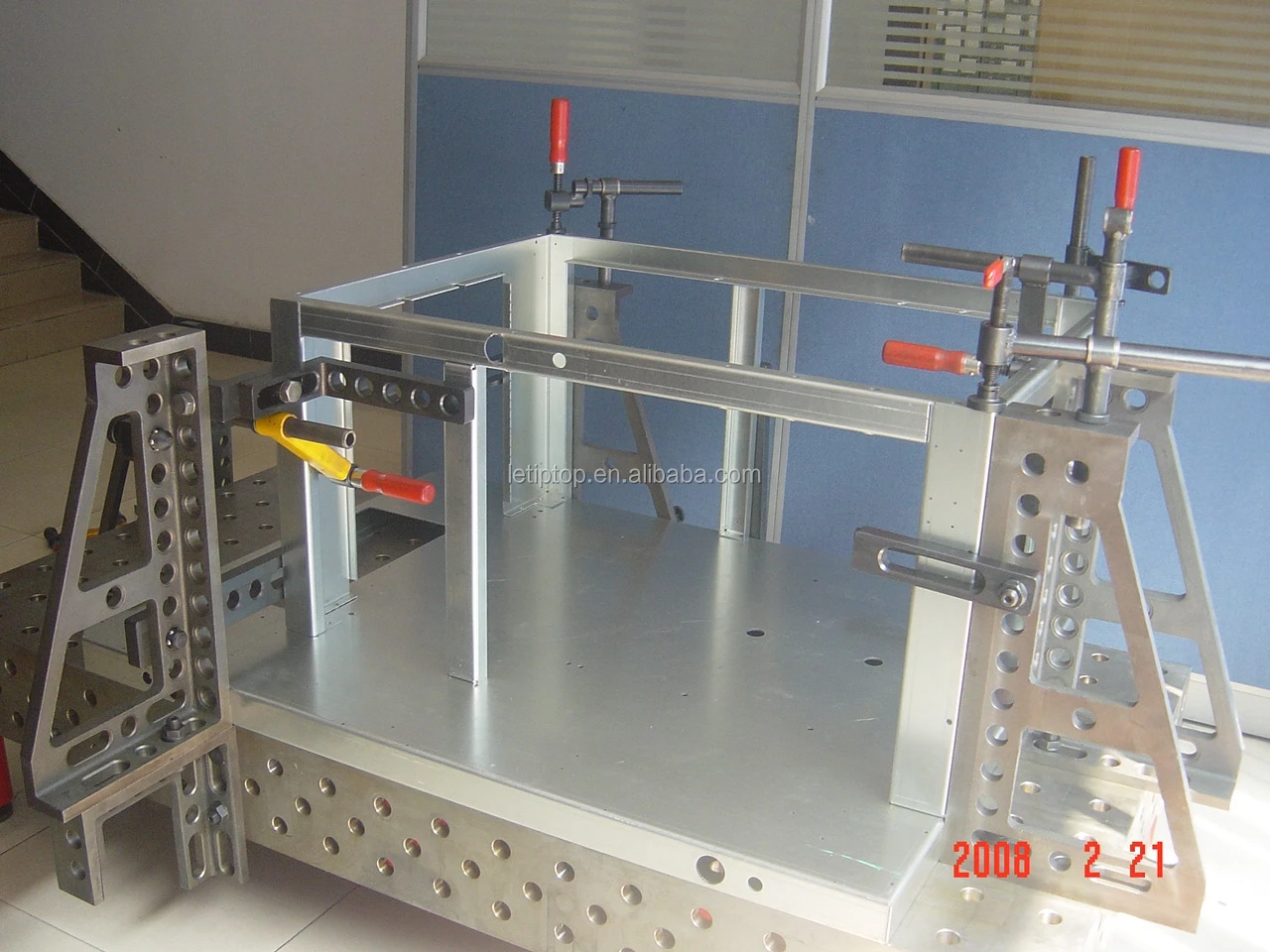

Product Application

2D Welding table: one working surfaces the locating piece can be installed on.

3D Welding table: five working surfaces the locating piece can be installed on. Also can be extended via any of its five working surfaces.

•\tFor its material divided into: Steel Welding Tables (1040) and Casting Welding Tables (GG25~30).

•\tFor its hole diameter divided into: D28 series and D16 series.

Diagonal Grid: D28 is 100*100mm; D16 is 50*50mm.

Supporting: legs, steel frame and hydraulic lift box, according to the requirement.

Components can be equipped after your selecting:

1, Tools for supporting: U-Shaped cube case, L-shaped cube case, Angle supporting, and Angle gauge

2, spare parts for Locating:

3, Tools for clamping and fixing

4, spare parts for locking working piece

5, Auxiliary Tools

Main Features

•\tAlmost all workpiece can be fixed precisely at certain points or surfaces with locating piece, adapting piece, fastening piece and supporting piece, in the process of assembling or welding.

•\tImprecise dimensions of workpiece can be adjusted during preliminary working process.

•\tIt is easy to use existing parts in the workshop to imitate workpiece assembly via CAD.

3D Steel Welding Table (D28):

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

3D Casting Welding Table (D28):

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

3D Steel Welding Table (D16):

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

2D Steel Welding Table (D28):

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

| \t | \t | \t |

Economical:

•\t Save much cost instead of reserving a lot of complicated and expensive traditional fixtures

•\t Applies to various working conditions without the need of any modification

•\t Easy and safe to operate.

Flexible:

•\tSolid enough to bear extremely heavy loads.

•\tFive surfaces, regular holes and grid lines(no inclined holes or T-shaped grooves)

•\tAny workpiece can be fixed and clamped on the table with locating pins

•\t3D welding tables can link together against any of its five surfaces.

Precise:

•\tAlmost all workpiece can be fixed precisely at certain points or surfaces with locating piece, adapting piece, fastening piece and supporting piece, in the process of assembling or welding

•\tImprecise dimensions of workpiece can be adjusted during preliminary working process.

Repeatable:

•\tIt is easy to use existing parts in the workshop to imitate workpiece assembly via CAD.

Widely applied in the manufacturing and processing of machines, machining equipments, railways and tracks, automobiles, motorcycles, ships, pressurized containers, sheet metals, classis and cabinets, testing and measurement instruments and steel constructions.

▶ ABOUT US

Jiangsu TIPTOP Machine Tools Co., Ltd. is a well known worldwide manufacturer of machines for sheet metal working, such as Hydraulic Ironworker, Hydraulic Shearing Machine, Press Brake, Plate Rolling Machine and Section Bender utilizing the most recent technologies and constantly refined by our design engineers to meet the most demanding market requirements for flexibility.

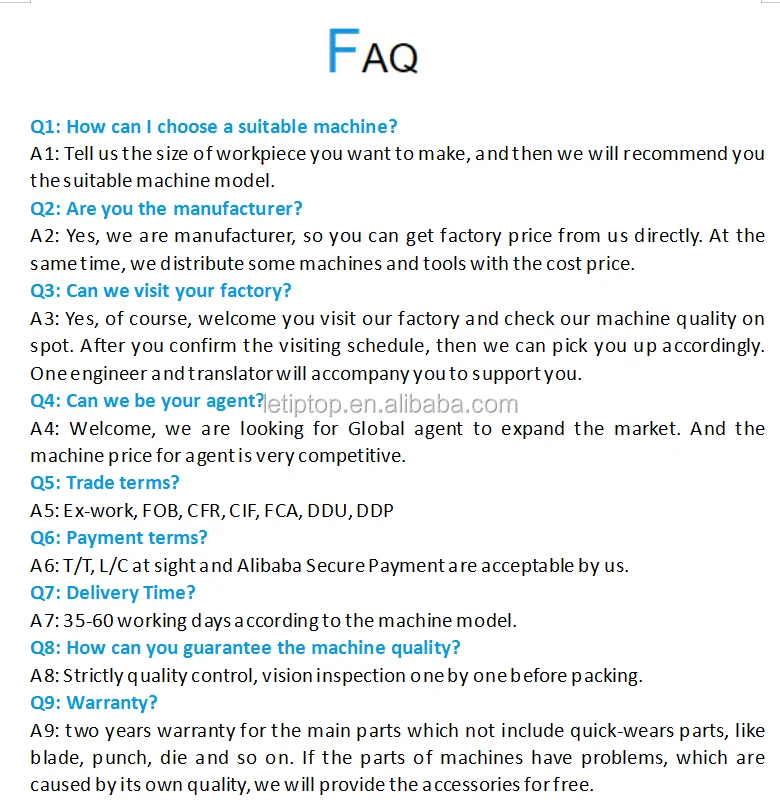

Pre-Sales Service

* Inquiry and technology support

* Technical documents

All labels on machines and lay-out drawings, Electrical diagram, Operation Manual, will be in English. The seller should send all necessary files to the buyer since the third week since project execution. All documents in hard copies should be also shipped with machines together.

* Quantity and quality guarantee

a.Quantity/Quality Discrepancy to destination port during transportation:

In case of quality/quantity discrepancy to destination port in transportation, the buyer should file claim within 30 days after the arrival of the goods at port of destination. The seller will not be responsible for any discrepancy of the goods caused by shipping company and other transportation organization and/or post office.

b.Guarantee period and after-sales services: 13 months since date of bill of lading

During this guarantee period, the seller will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by your incorrect operations, the seller will provide the buyer spare parts at cost price.

* View our Factory.

After-Sales Service

* Arrangement for inspection, installation and testing work

a. After all machines are delivered to customer's factory; Buyer is responsible for all preparation work, e.g. electricity supply, water supply, labors and cranes, etc.

b. The buyer will prepare for visa application for their engineers, who are responsible for guide of machine installation and testing at the Buyer's factory.

c. The Buyer will buy the round-trip air ticket for Engineer if visa application is approved. The buyer is also responsible to bear expenses generated, e.g. visa formalities, meals, accommodation and allowance of USD80 per day for each engineer.

d. Engineer will give free training lessons to labors in buyer's factory.

*The seller will charge the buyer cost price of spare parts beyond one year and provide long-term technical guide.

*2 years quality warranty

| \t | |

| \t | \t |

| \t | \t |

| \t | \t |

Похожие товары

Разноцветные многоразовые пластиковые соломинки в ассортименте, трубочки для пениса для свадьбы, девичника, товары для девичника

Новый в коробке оригинальный Om Ron AC R88M-K1K520C-BS2 R88M-K2K020C-BS2 R88M-K3K020C-BS2

Для малышей и детей постарше, для детей обучающие и рисунком оленя, подарок сотовый образовательные игрушечные мобильные телефоны для музыкальный телефон детские игрушки огни воспроизведения музыки игрушечный телефон

Thinuna UR-200 II UHF 2-канальный беспроводной микрофон для сценического выступления караоке KTV пение Профессиональный портативный микрофон

Высокомощная конструкция двигателя, электрическая реверсивная Виброплита, трамбовщик для продажи

Высококачественное оборудование для предварительного прессования по лучшей цене Термальная машина производства CTP Yintech

Оптовая продажа, цифровые электронные весы Rukioo с шлифовальной машиной и коробкой, светодиодные электронные весы 500 г для курения

Новые поступления

Новинки товаров от производителей по оптовым ценам