Распылитель флюса THT для паяльной машины PCB/распылитель канифоли LT500C

- Категория: >>>

- Поставщик: Beijing Glichn S&T Development Co. Ltd.

Сохранить в закладки 62141419780:

Описание и отзывы

Характеристики

1. Flux Sprayer Coater LT500C use of imported Danfoss nozzle, atomization effect is excellent, spray evenly and make the flux flux better play.

2. Save the flux. Free from volatile, reduce costs.

3. Improve the flux activity and improve the welding quality.

4. Simple operation, you can step on the switch control.

5. Coated flux is more uniform.

6. Flux spray furnace shell made of 1.2MM iron plate. Teflon surface coating high temperature paint. The use of imported nozzle, the nozzle is made of brass interior, the inner wall of a unique hand-made grinding process, to avoid being flux corrosion. The atomization effect is good, the spray flux is uniform and the flux flux is good, the oxide on the surface of the circuit board and the plug surface can be completely removed, and a uniform oxide film is formed on the circuit board, and the surface tension is small. The effect of the solder pad is the best.

7. The principle of the spray furnace is the nozzle through the nozzle of the liquid flux atomized into a small particle, coated on the circuit board surface, improve the quality of welding, saving more than half the amount of flux.

Model | LT500C |

Voltage Power | AC220V 50W |

Nozzle diameter | 1.3mm |

Water gushing quantity | 0-360ml/min |

Overall size | 360x305x650mm (L*W*H) |

| Atomization average particle size | 100um |

| Nozzle distance products | 20-30cm |

Packing method:

1)Standard box package for light and small item;

2)Strong wood package for heavy and large equipment;

Shipping way:

1)By air ,for sample and small package ,wordwide express like DHL,UPS,FedFX,EMS....

2)By sea, for large package and quantity;

3)By car or other ways as customer requested;

GLICHN found in 2010,Specializing in SMT equipment manufacturing services and sales of peripheral products. Factory is located in shunyi district of Beijing and shenzhen baoan district

SMT class:pick and place machine,small and middle size reflow oven, manual and semi-automatic solder paste printer,PCB loader and unloader,PCB magazine rack,SMD component counter,solder paste and chip production line etc.

THT Class:wave soldering machine, Spray tin stove,cut foot and forming machine,Plug-in production line etc

Others :Spin coater,Dispensing machine,nozzles,feeder,belt ,driver, motor,cylinder,High temperature tape,valve,etc

1. We’ll have a good check and a test before shipping out.

2. We provide you the friendly English User manual or the operating videos for free;

3. 24 hours technical support by email or Skype or Trade Manager or Calling.

4. 1 year machine parts free warranty;

5.Engineers available to service machinery overseas.

1 set machine, mixed order is also welcome.

a. How can I buy this machine from you? ( Very easy and flexible !)

b.Consult us about this product on line or by e-mail.

c. Negotiate and confirm the final price , shipping , payment methods and other

terms for machine.

d.Send you the proforma invoice and confirm your machine order.

e. Make the payment according to the method put on proforma invoice.

f. We prepare for your machine order in terms of the proforma invoice after confirming your full payment. And 100% quality check before shipping.

g.Send your machine order by air or by sea.

Why choose us ?

a. Best price & Best shipping & Best service

b. Ten years of experience in research and development production and sales

c. Six years of alibaba gold supplier

d. Trade assurance

Похожие товары

ZSY цветная эластичная лента из органзы с кружевной отделкой Цветочная для платья слои мигающей пленки плиссирующие сетчатые

Высококачественная айтоновая кислота cas № 97-65-4

200 м глубина для геолого-разведочных работ портативная буровая установка бурения скважин на воду буровые установки продажи XY-1B с завода в наличии

оборудование для производства полиэфирного волокна пэт

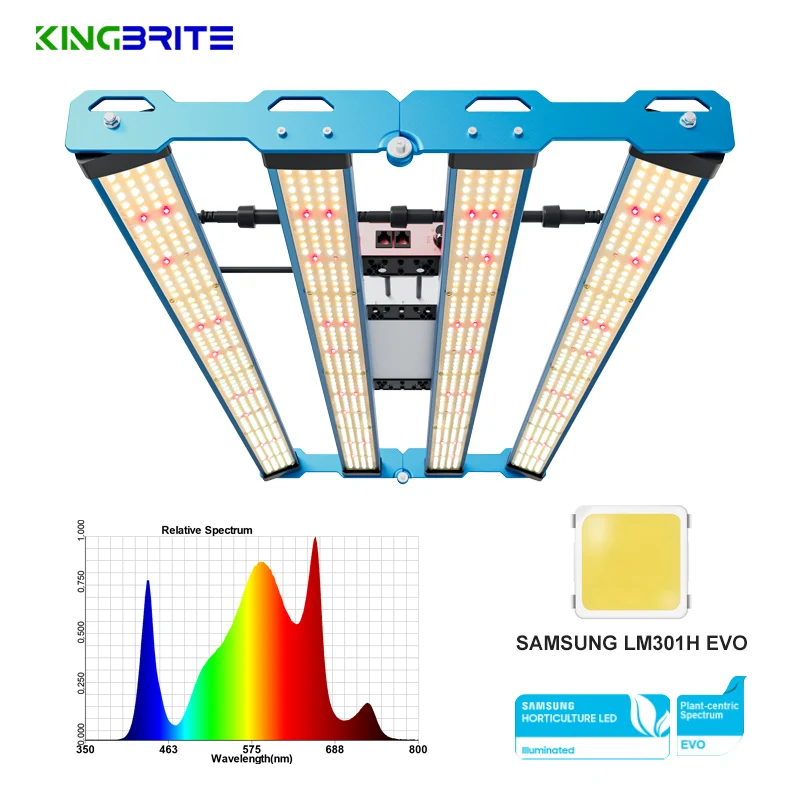

2024 KingBrite 320 Вт Samsung LM301H EVO P55 светодиодный светильник для 3x3 футов или 2x4 фута палатки PPE(umol/s/W): 2,889

2021 Горячая распродажа! Класс CATL 3,7 V 148Ah 150Ah 153Ah NCM литий-ионный аккумулятор сотового NMC литиевая батарея для аккумуляторная электротележка

Высококачественные карбоновые полимерные праймеры GTR стильные боковые юбки для Mercedes Benz AMG GT GTC GTS обвес переднего бампера

Новые поступления

Новинки товаров от производителей по оптовым ценам