Сепаратор для переработки твердых отходов сепаратор травяного тока разделение цветных металлов

- Категория: >>>

- Поставщик: Qijin Magnet Co. Ltd.

Сохранить в закладки 62146826906:

Описание и отзывы

Характеристики

Solid Waste Recycling Separation

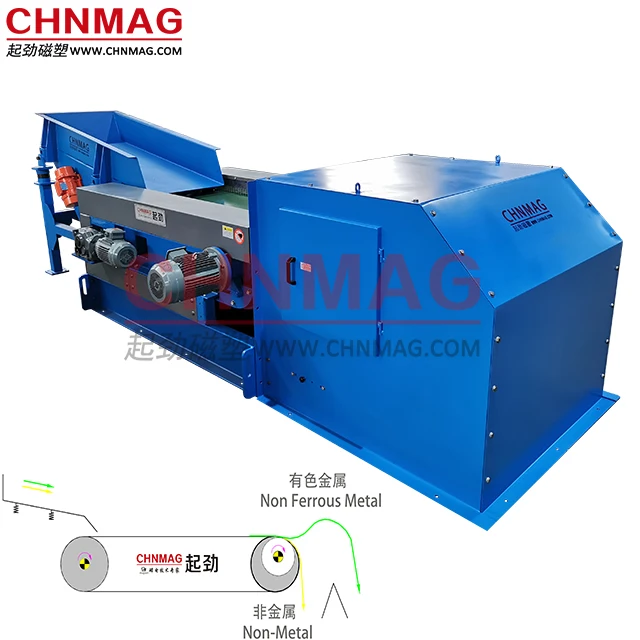

Non Ferrous Metal Separation - Eddy Current Separator Introduction:

CHNMAG Eddy Current Separator separates nonferrous metals such as aluminum, die-cast metal, and copper from nonmetallic material.

Eddy Current Separator Features:

The Eddy Current separator separation results can be affected by the following factors

• magnetic rotor speed

• magnetic rotor angle setting

• belt speed

• strong and deep magnetic field

So we optimize our design accordingly

• magnetic rotor speed - 0-3000rpm rotation speed

• magnetic rotor angle setting - manually adjustable rotor position in drum shell

• belt speed - adjustable speed motor drive

• strong and deep magnetic field - high grade NdFeb magnet system with multiple poles in rotor

Working Principle:

Material is fed onto the conveyor belt of the eddy current separator, which moves it across the magnetic rotor where separation occurs. The magnetic rotor is surrounded by (but not attached to) a wear shell which supports the conveyor belt. This allows the rotor to spin independently and at a much higher speed than the wear shell and belt. When a piece of nonferrous metal, such as aluminum, passes over the separator, the magnets inside the rotor rotate past the aluminum at high speed. This forms eddy currents in the aluminum which in turn create a magnetic field around the piece of aluminum. The polarity of that magnetic field is the same as the rotating magnet, causing the aluminum to be repelled away from the magnet. This repulsion makes the trajectory of the aluminum greater than that of the non-metallic, allowing the two material streams to be separated.

Products Photos:

Advice:

CHNMAG Overband Magnet, Magnetic Pulley, Magnetic Drum are recommended prior to the eddy current separator.

An eddy current separator is NOT designed to be a source of magnetic ferrous separation. Serious damage will occur if magnetic separators such as pulleys or drums are not used to remove the ferrous metal from the burden before it reaches the eddy current system. At least two stages of magnetic separation.

Capacity:

Capacity per 1000mm Feed width (Tonnes/hour)

PET Flake | -15mm | 2-3 |

Glass Cullet | -40mm | 20.0 |

Car frag | -12mm | 5.2 |

Car frag | 12-30mm | 12.5 |

Car frag | 30-70mm | 20.0 |

Shredded refuse | -50mm | 18.0 |

Shredded refuse | 50-150mm | 20.0 |

Plastic Al | -10mm | 10 |

Copper Pb | -8mm | 7 |

Copper PVC | -6mm | 2.25 |

Ferrous Metal Separation

Permanent Suspended Conveyor Belt Separator Introduction:

QJRCY-L magnetic separator for conveyor belt (suspended overband magnetic separator) offer superior strength and reliability and are designed for separation of ferrous metal from kinds of belt conveyed products. The advanced design and construction make suspension overband magnet ideal for use in recycling, fire shredding, wood chip, and demolition applications.

Installation Position:

Conveyor belt magnetic separator Features:

1. Suspended Magnetic Separator for Conveyor Belt provide powerful deep reaching magnetic circuit design to penetrate heavy product burdens.

2. Strong magnetic field intensity, high gradient and strong attractive force.

3. The unique stainless steel plate-armored belt can protect the belt from damage by sharp ferromagnetism material.

4. Non-excitation and self-cleaning will bring us energy saving and convenience in operation.

5. The belt of Overband Magnetic separator has self-adjustment function and the special sealed bearing block ensure the stable working of suspended overband magnetic separator in harsh environment.

6. Safe specification meets the international standard.

Data Sheet:

| Type | Belt Width (mm) | Belt Speed (m/s) | Suspension Height (mm) | Working Mode | Motor Output(kw) | Weight (kg) |

| QJRCY-L-50 | 500 | <4.5 | 150 | Continuous | 1.1 | 590 |

| QJRCY-L-65 | 650 | 200 | 1.5 | 730 | ||

| QJRCY-L-80 | 800 | 250 | 2.2 | 950 | ||

| QJRCY-L-100 | 1000 | 300 | 3.0 | 1700 | ||

| QJRCY-L-120 | 1200 | 350 | 3.0 | 1950 | ||

| QJRCY-L-140 | 1400 | 4.0 | 2350 | |||

| QJRCY-L-160 | 1600 | 4.0 | 2700 |

Electromagnetic Separator for Conveyor Belt:

QJRCDD (Self Cleaning) and QJRCDE (Manual Cleaning) Electro Magnet Separator series are of long work shift hanging over belt conveyor. Some parts like stand, roll, and iron discharging belt are available.

They can throw away the iron materials continuously which have been attracted into iron collecting box.

They are suitable for removing iron magnetic foreign articles from materials of thicker bed and bigger granularity that are rich in iron like ores, coal, and hard coke.

1. Magnetic circuit adopts computer simulation design, so it has a deep penetration strong magnetic force and high field gradient and can provide max attracting force.

2. The shell of hanging elctromagnetic separator is welded by sealed steel plate and has gone through a strict test of air-proof. Meanwhile, a vacuum filling epoxy resin has been added between coil and shell to enable the equipment work well even in harsh working conditions.

3. Natural cooling mode is adopted which causes a less risk of fault occur.

4. The Electro Magnetic Separator can remove 0.1~35 kg materials from non-magnetic materials and the removing rate can up to 95% or more.

Похожие товары

Oilgear гидравлический насос pvg-130-f1uv-lsfy-p-1nnsn переменной поршневой насос импортируется из хорошего качества Быстрая доставка

Пользовательские сильные мухи ловушки насекомые клейкая доска насекомые вредители уличная ловушка для мух для Aphids грибок

Китайская Фабрика API 5L ASTM A106 SCHXS SCH40 SCH80 SCH160 2 3 20 24 28 дюймов бесшовная труба из углеродистой стали по выгодной цене

Золотые металлические дизайнеры, современный уличный вентилятор для ванной комнаты в индийском стиле

Садовые колесные полки BY250 мини самосвал, садовый погрузчик, полноприводная тачка самосвал

Промышленный Блок центрального кондиционера 30usrt одноблочная упаковочная система кондиционеры

Оптовая продажа мини-экскаватор 1 тонна 1,2 тонна 1,5 тонна 2 тонны 2,2 тонн экскаватор с нулевым хвостом с гидравлическим пилотом

Новые поступления

Новинки товаров от производителей по оптовым ценам