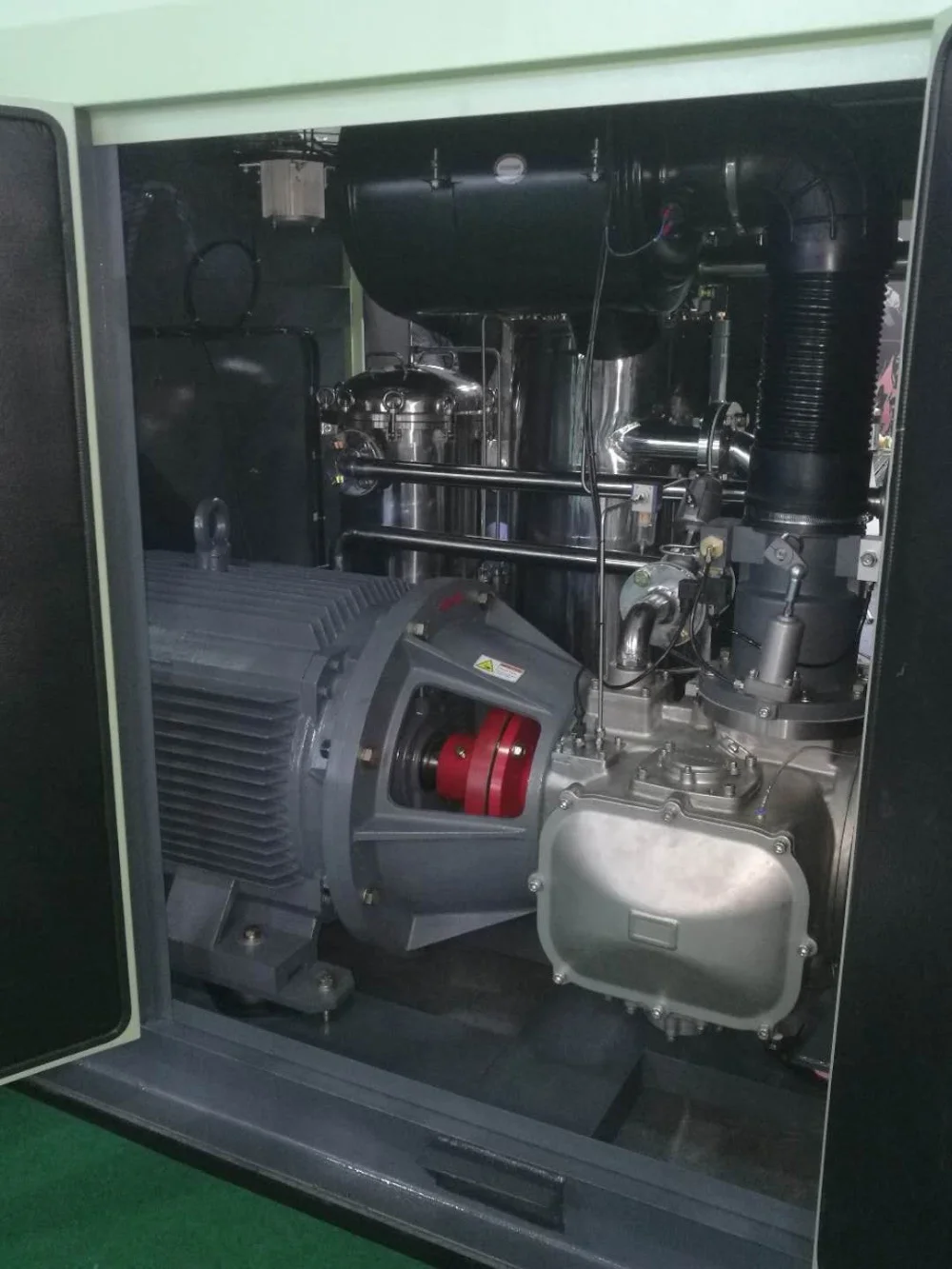

30 л.с. 22 кВт 100% безмасляный водный охлаждающий Стационарный винтовой воздушный компрессор

- Категория: >>>

- Поставщик: Keepwin Technology Hebei Co. Ltd.

Сохранить в закладки 62147745618:

Описание и отзывы

Характеристики

30HP 22KW 100% Oil Free Water Cooling Stationary Screw Oil Free Air Compressor

Advantages

1.\tLarge displacement: Displacement 10% higher than ordinary piston compressor.

2.\tEnergy-saving: Compared with piston air compressor, this series of models for the new national standard two energy efficiency products, excellent energy saving.

3.\tEasy to operate: 24 hours unattended all day work, free load automatically start, full load automatically shut down.

4.\tStrong stability: Under long time working, displacement and pressure stable, no crash phenomenon, low failure rate.

5.\tRemote monitor:Computer remote monitoring data, normal operation data, and fault alarm, unattended

6.\tAir End: No vibration and low noise interpret perfectly the genuine made in Germany. Big rotor, low speed of rotation and direct connection.

7.\tMotor: First-class motors are adopted, with the level of protection being IP54 and insulation level being F.

8.\tEasy to operate: It is of beautiful appearance, stable performance and economy.

Suitable for :

Industrial Equipment | Oil & GasCoating | Plastics

Pipelines | Blow Molding | Printing Service

Tobacco Factory | Steel Industry | Railway Head Project

Power Plants | Oil Refinery | Color Sorter Machine

etc

SPECIFICATIONS for Screw Compressor | ||||||

Product Name | 30HP 22KW 100% Oil Free Water Cooling Stationary Screw Oil Free Air Compressor | ||||

Air Delevery | 0.5-3.42m3/min (Note: 1cfm/min=0.0283185m3/min) | ||||

Color | Black and Blue (or any color can be customize ) | ||||

Size | 1100*850*1220mm | ||||

Power | 22KW/ 30HP | ||||

Working Pressure | 10bar(1.0Mpa) (Note:1bar=14.5psi) (another pressure can be choos:7bar,8bar or 13bar) | ||||

Outlet Pipe Dia | G1" | ||||

Lubrication oIL(L) | 15L | ||||

Dew point | 3-10℃ | ||||

Sound(dB) | 63dB | ||||

A) Temperature: The ambient temperature varies with the seasons, Max ambient temperature: + 40°C ;The min ambient temperature is: -15°C

B) Altitude: no more than 1000m;

Note: When the ambient temperature and elevation are different from the above regulations, the regulations of GB755 shall be followed.

C) Humidity: The monthly average maximum relative humidity is 90% and the monthly average minimum temperature is not higher than 25℃ (factory).

D) Rated frequency: 50Hz;

E) Working system: S1;

F) Motor Rated voltage: 220V, 230V, 240V, 380V, 400V, 415V, 660V, 690V, 720V, 220V/380V, 230V/400V, 240V/415V, 380/660V, 400V/690V, 415V/720V.

Note: When there are special requirements for frequency, voltage, ambient temperature, altitude, etc. Please put forward when ordering.

What is the reason for the excessive current of screw air compressor?

The normal current of screw air compressor is rated current plus 1.15%.

1. The ambient temperature of screw air compressor is too high. Processing method: screw air compressor with air duct exhaust equipment;

2. The three-phase voltage of screw air compressor is unstable, under-phase and over-low (less than 10%). Processing methods: Please improve the power system of the plant;

3. Failure of motor temperature controller of screw air compressor. Processing methods: replacing the air compressor temperature controller;

4. Failure of overload protector of screw air compressor. Processing methods: replacing overload protector of air compressor;

5. The contact of screw air compressor starter is not good. Processing methods: air compressor starter contacts for maintenance;

6. Blockage of oil-gas separator in screw air compressor. Processing method: When the pressure difference of air compressor is greater than 0.8-1 kg, the oil-gas separator should be replaced.

7. The motor bearing of screw air compressor is not oiled. Processing method: add butter to motor bearing;

8. The motor bearing of screw air compressor is damaged. Processing methods: replacement of motor bearings;

9. The motor of screw air compressor has poor insulation. Processing methods: remove the motor to do insulation strengthening treatment;

10. The motor wiring of screw air compressor is loose. Processing method: Re-lock motor wiring;

11. The air inlet of screw air compressor is blocked. Processing method: Clean and maintain the air compressor inlet;

12. Blockage of air filter in screw air compressor. Processing method: Replace air filter.

High efficient energy saving Screw air end

Stage type: Single Stage

Using the most advanced 3rd generation 5:6 rotors and the optimized rotor.

Energy saving 1:1 soft direct transmission:The speed of the motor and the rotor is always consistent, without any transmission loss,reduced the starting torque , improved the efficiency, prolonged the service life, and saved the electric energy.

Energy Saving Intake Valve

Name: Bliwing Cylinder

The intake valve can be adjusted between 0 to 100%.The solenoid valve ,atmospheric valve and other valves are integrated. Installed a special rapid ventilation valve on it,so it well eliminated the unloading noise. Our high efficient intake valve is helpful for air compressor to expand the service life, reduce the electrical consumption to save energy ,balanced air supply and air consumption.

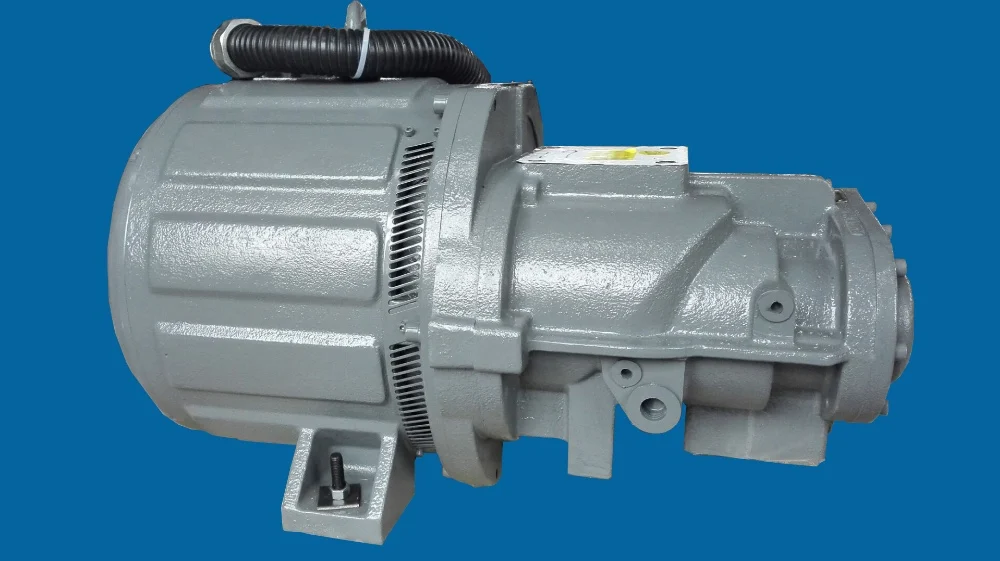

Efficient motor using the imported SKF heavy bear

Motor protection level: IP54 / IP55

Motor insulation class: Class F

Temperature Rise Class : Class B

Transmission mode: elastic coupling

High protection level, that effectively prevent the dust and water into the motor, greatly extend the machine's service life

Scerw Compressor Air Cooler

The cooling systemCooling system:combined design of oil cooling and gas cooling, reduce weight, maintain simple and reduce maintenance costs.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Compressor Packaging | ||

Size | 900 (L) * 850 (W) * 1000 (D)mm | |

Weight | 280kg | |

Packaging Details | Best Efficiency Energy Saving Keepwin Compressor is the best efficiency energy saving manufacture for the customer.According the customer's requirements to customize OEM or ODM products. And in order to let our customer to recive the whole good quality products,we packed all of the goods by fumigation wood case free for them. | |

Compact Mounted refrigerate air dryer 500L air tank Screw Air compressor

91.8% Response Rate

More big F.A.D Air Delivery Energy Save Two Stage Screw Air Compressor

91.8% Response Rate

Factory supplier OEM available 4KW-355KW 4bar 40bar Screw Air Compressor

91.8% Response Rate

Hot selling Chinese belt driven refrigerator air dryer 220L Air Tank Rotary Screw Air Compressor

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine.

OEM Brand 30KW Inverter Controller VSD Screw Air Compressor

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine.

New Arrival OEM Customize service Industrial gas compressor 30KW VSD Screw Air Compressor

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine.

Q1: What's your delivery time?

A: Generally 5-10 days if the goods are in stock. Or it is 20-35 days if the goods are not in stock, it is according to quantity.

Q2: How long is your air compressor warranty?

A: Usually 1 year /12 Months for whole compressor machine, 2years/24months for air end (except maintenance spare parts.). And we can provide further warranty if necessary.

Q3: How long could your air compressor be used?

A: Generally, more than 10 years.

Q4: Can you do OEM for us?

A: Yes, of course. We have around two decades OEM experience.And also we can do ODM for you.

Q5: What's payment term?

A: T/T, L/C, D/P, Western Union, Paypal, Credit Card, Trade Assurance and etc. Also we could accept USD, RMB, GBP, Euro and other currency.

Q6: How about your customer service?

A: 24 hours on-line service available. 48hours problem sovled promise.

Q7: How about your after-sales service?

A: 1. Provide customers with intallation and commissioning online instructions.

2. Well-trained engineers available to overseas after-sales service.

Q8. Are you factory?

A4: Absolutely! You have touched the primary sources of Air Gas Compressor. We are factory.

How to contact with us?

Send your Inquiry Details specifications as the Below required:

A. The gas compression medium

B. The flow rate: _____Nm3/hr

C. Inlet pressure: _____ Bar

D. Discharge pressure: _____ Bar

E. Inlet temperature

F. Cooling water temperature as well as other technical requirement.

For more questions, kindly contact us: keepwin at keep-win dot com

Petrochemical flammable gas 100% purity Oil Free Diaphragm Compressor Medical High Pressure Compressor

Похожие товары

Поршень для RENAULT RVI 123 мм 2095900 5001855845 5001845663 40074600 87-135500-00 8713550000 поршень

Профессиональные китайские производители распродажи 220 В 90 Вт маленький однофазный вентилятор переменного тока капот двигатель электрический вытяжной вентилятор двигатель цена

Прямая продажа от производителя, горячая распродажа, Электрический Потолочный двигатель вентилятора переменного тока 115 в

Высокое качество, китайское Оригинальное производство, кухонная комната, электрическая вентиляция переменного тока, вытяжной вентилятор, двигатель

Производитель HM2/IE2 электродвигатель вентилятора переменного тока 30 кВт для цементного смесителя

Электродвигатель вентилятора кондиционера переменного тока

Воздушный вентилятор, двигатель коробки передач от производителя, алюминиевый легкий однофазный индукционный электродвигатель переменного тока

Новые поступления

Новинки товаров от производителей по оптовым ценам