Лидер продаж машина для производства кондиционирования воздуха канальная линия 2 резки рулонных

- Категория: >>>

- Поставщик: Anhui Preda Machinery Manufacturing Co. Ltd.Anhui Ltd.

Сохранить в закладки 62149461804:

Описание и отзывы

Характеристики

Hot sale air conditioning production machine duct line 2 for coil roll shearing

Product Description

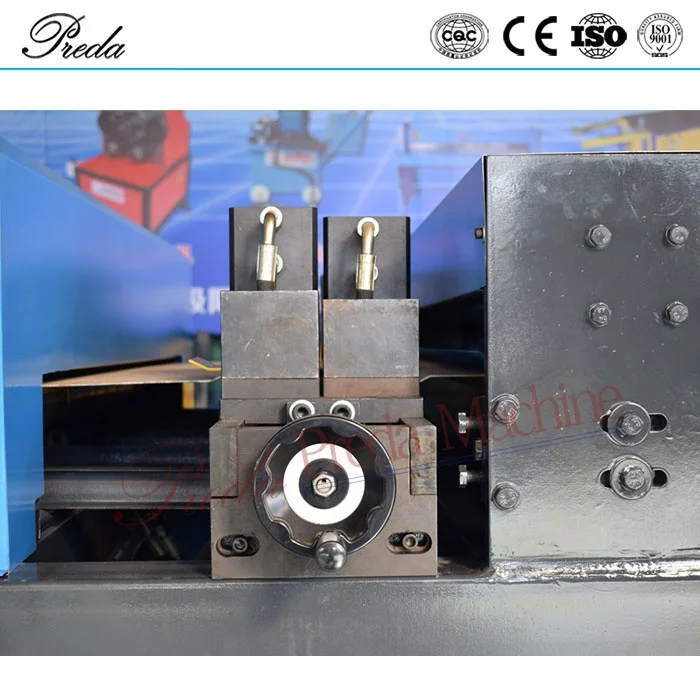

Preda auto duct line is a device for the production of rectangular ducts, whose automated production process replaces traditional manual manufacturing. The auto duct line 2 is mainly used to shear plate. Its structure is leveling, beading, notching (capable of sharp notching, TDF notching) and plate shearing.

Workstations and functions:

1.Electric double decoiler (2 sets of rollers) driven by independent frequency controlled motors.

2.Multi-functional main body with capability of leveling, beading, notching(capable of sharp notching, TDF notching) and plate shearing.

3. Mitsubishi computer controlling system and software.

4. Mitsubishi and Siemens electric box and electrics.

Main Import Configuration:

1) MITSUBISHI Display and PLC.

2) MITSUBISHI Frequency Converter.

3) Taiwan High Temperature Resistant Tubing.

4) Taiwan high quality Pump.

Basic Configuration:

· Two electric coil cradles, 2 material trays (5-7 t each roll)

· One rack

· One host (duct line 2 host)

· One set of computer controlling system

Model | Thickness (mm) | Max width (mm) | Working speed (m/min) | Weight of coil (T) |

Dimension (mm) L*W*H |

Power (kw) |

Weight(T) |

AML-3-1300 | 0.5-1.2 | 1300 | 0-18 | 7 | 1900*1950*1350 | 7 | 3 |

AML-3-1500 | 0.5-1.2 | 1500 | 0-18 | 7 | 1900*2150*1350 | 8.5 | 3.2 |

More About Preda Machine Auto Duct Line 2

Optimized linear structure makes the whole auto duct line beautiful in appearance and fast in production. There are five specifications for the auto duct line. They are auto duct line 2/ auto duct line 3/ auto duct line 4/ auto duct line 5/ u shape auto duct line 5. These auto duct lines are all manufactured by Preda Machine.

Preda duct line 2 is a multi-functional main body with capability of leveling, beading, notching(capable of sharp notching, TDF notching) and plate shearing. It is controlled by a touchable computer controller for fully automated production.

Preda auto duct line have MITSUBISHI Display and PLC, MITSUBISHI Frequency Converter,Taiwan High Temperature Resistant Tubing,Taiwan high quality Pump and etc. Preda auto duct line can finish processing a whole roll of material to meet the dimensions of the production duct. It is labor and time saver, high efficiency.

Stepping out from traditional processing method, preda auto duct line saves time greatly and significantly improve production efficiency. The auto duct line is also one of the necessary equipment in the production of HVAC ducts. The automation is more popular with people.

When you are ready to upgrade your original small macachine, Preda's duct line 2 will be your best beginning. This is also the sign that you really hieve the beginning of automated production.

The transport cost as reference please contact us to get more clearly transport cost directly. Different port of countries will have different cost!

FAQ

1. How to get a accurate quotation from Preda Machine?

Provide the machine name you want, the specifications you need and the quantity of machine, we shall quote accordingly!

2. What's the shipping cost from China to your country?

Please kindly tell us your nearest port to your place. We have reliable shipping forwarder to insure cheap, safe, convenient and timely delivery via sea.

3. Payment terms, MOQ, warranty, FOB.

Payment terms: 20% TT paid in advance, the balance of 80% before the shipment.

Minimum order quantity: 1 set of any machine of Preda Machine.

Delivery time : 5days after order confirmation. As a real manufacturer, we normally stock our machine in at least 5-10 sets including auto duct line 5, auto duct line 3, auto duct line 2!

And at least 20 sets each for TDF flange forming machine, Pittsburgh lock former, TDF folding machine, Pneumatic folder and etc...

Shipping terms : FOB, CFR, CIF and etc.. according to your requirements.

Warranty:24 months after our machines arriving at you.

4. What's the package?

Fumigation-free plywood case for LCL and nude package for full container basis such duct production line 5, duct auto line 3, duct line 2...

5. What about commissioning service?

We can offer commissioning service, the buyer need to pay for all the transport, salary, hotel, meals for Preda Machine technicians caused during the service period.

6. What's policy for guarantee and broken parts?

Warranty period of equipment is two years, during which the broken parts and spares caused by quality can be offered free. After guarantee period, all broken parts or easy wearing parts will be charged in a most competitive price ever in the market!

Похожие товары

Матрас пуховое одеяло гостиничное Китай из микрофибры 3D альтернативная гостиничная наматрасница накладка на

Nylon Printer Ribbon for NCR 5685

Competitor Jiu Jitsu Gi Kimono BJJ 2025 With Customized

Абразивный монтажный камень для Dremel 10 шт./компл. роторные инструменты шлифовальный колесная головка

5 People Capacity Portable Acrylic Balboa Hottub Outdoor Spa Hot

New Mini Moto 110cc Dirt

High Quality Burma Teak Veneer for Doors Light Color

Новые поступления

Новинки товаров от производителей по оптовым ценам