Интеллектуальные роботы КР эффективно комбинируют резку и сварку

- Категория: >>>

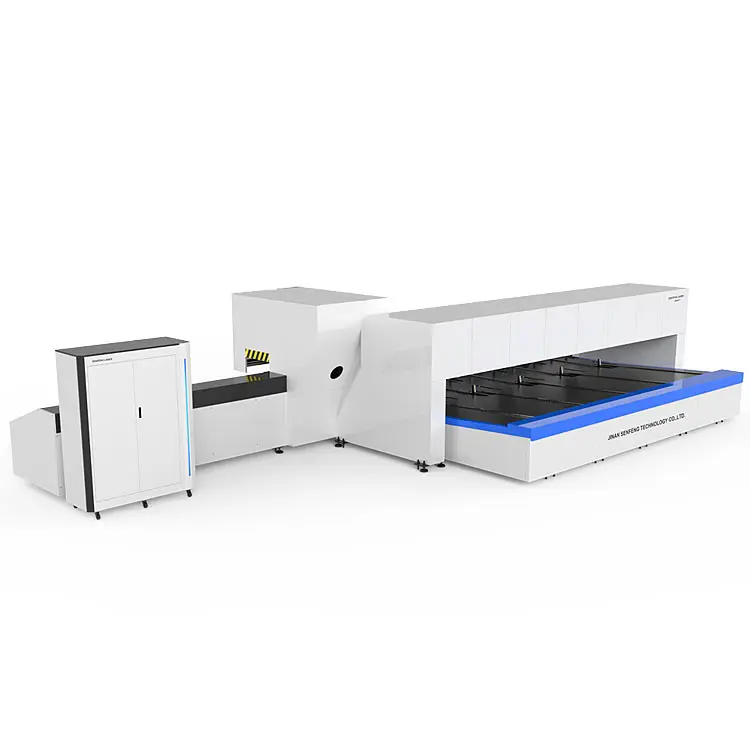

- Поставщик: Jinan Senfeng Laser Technology Co. Ltd.Jinan Ltd.

Сохранить в закладки 62160859881:

Описание и отзывы

Характеристики

SFR Intelligent robots combine cutting and welding effectively

The 3D robotic laser automation system SF-20RFLS integrates laser cutting, welding, cleaning and marking functions to help customers achieve flexible planning, production tracking and quality monitoring, which not only improves equipment utilization, but also reduces quality unqualified conditions. Manufacturing costs, reduced lead times, and intelligent and digital production.

1. Using the FNUCM-20iA robot mechanism, the laser cutting, welding, cleaning, marking and processing systems are organically combined to realize the innovation of laser cutting, welding, cleaning, marking and processing systems, ensuring the stability of the working process and High precision.

2. Compared with the traditional welding method, laser welding has the characteristics of high speed, deep welding depth and small deformation. The weld strength is higher than the workpiece itself, and the weld quality is stable.

three. The combination of laser marking and robotic system will greatly expand the application range of laser marking. It can realize marking according to different workpieces and truly realize various functions.

four. Combine laser cleaning with a robotic system to improve positioning accuracy and selectively clean according to customer needs.

5. Customized workbench, customized workbench according to customer requirements, highly integrated PLC control system will provide customers with complete solutions, all control systems can be operated on the screen, easy to learn and operate.

1. Effective combination of cutting and welding, fast cutting speed, good weld density and high strength

2. Laser heat concentration, fast welding speed, small thermal deformation

3. High production efficiency, improve the working environment of workers, and control the product cycle

4. The product consumes less energy, the use cost is low, and the maintenance is simple and convenient.

5. Adopting Ricoh fiber laser, the performance is stable, and the overall quality of the product can be guaranteed.

6. Can design multi-station work together, take turns loading and unloading

Can cut a variety of metal sheets, pipes, mainly for stainless steel, carbon steel, manganese steel, copper, aluminum, galvanized sheet, a variety of alloy sheets, rare metals and other materials for rapid cutting

Jinan Senfeng Technology Co., Ltd. The company is a professional laser machinery manufacturer. Founded in 2004, it is located in Jinan Innovation Zone, China. It is a world-renowned laser cutting machine manufacturer with 15 years of experience. It has 3 qualified production workshops with a plant area of over 50,000 square meters. With more than 50,000 employees, we specialize in CO2 laser cutting machines, laser engraving machines, laser marking machines, and metal fiber laser cutting machines. We have more than 60 R&D teams to ensure your machine quality and design. We are waiting for you at Senfeng!

Похожие товары

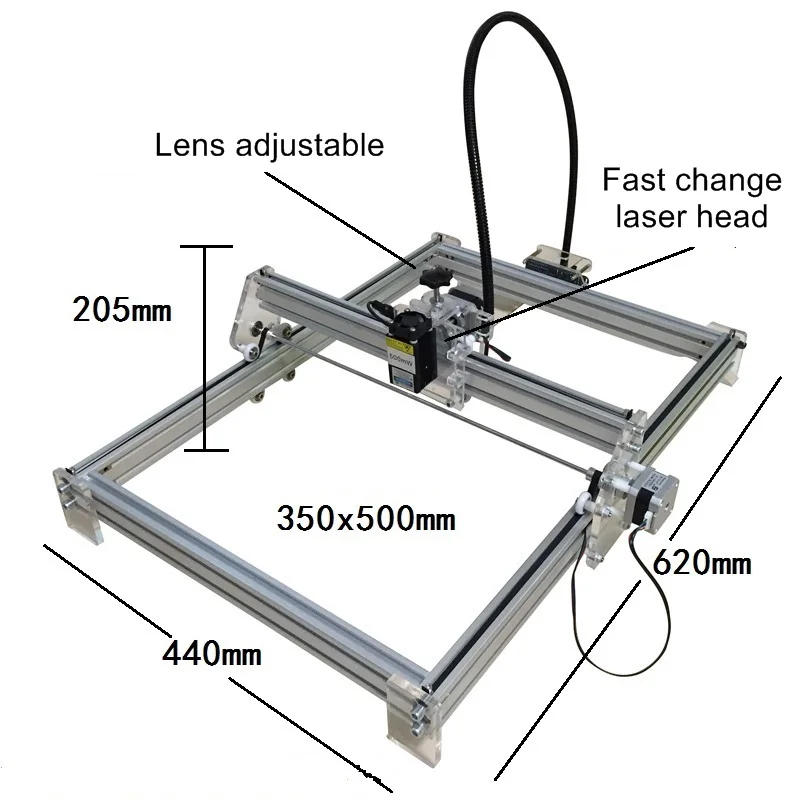

9060/1390 лазерный гравер CO2 станок для лазерной резки высокоскоростной прецизионный гравировальный из Китая деревянная подставка растений

Ospri высокомощная интеллектуальная автоматическая фокусировочная режущая головка 6 кВт LC608/8 LC808 для волоконно-лазерной режущей машины

Высокоточные лазерные режущие станки большого формата 6000 мм x 2500 для стального металла

Полностью Автоматическая компьютерная машина для резки термоусадочных труб резиновая силиконовых

Jinan Senfeng бренд Высокая скорость SF6020T станок волоконной резки для трубки

Разобранный мини лазерный гравировальный станок LY 500 мВт сине-фиолетовый 3550 регулируемый по высоте размер резьбы 35*50 см

Forsun 2 кВт 3 6 CNC волоконно-лазерная машина для резки металлических пластин FS3015L мощность лазера 1 5 Вт

Новые поступления

Новинки товаров от производителей по оптовым ценам