0.5Ton емкость алюминиевая оболочка индукционная печь медь плавильная машина

- Категория: >>>

- Поставщик: Henan Rongke Electrical Manufacturing Co. Ltd.

Сохранить в закладки 62185773676:

Описание и отзывы

Характеристики

aluminium shell 0.5Ton capacity intermediate frequency induction electric copper melting furnace

Our factory can built induction melting furnace and melting system shop for almost all of the copper and copper alloy application, from removable crucible induction furnace melting just small capacity brass custom made casting to casting huge bronze ingots, Rongke advanced induction technology makes copper and copper based alloy manufacturer and ingot maker can through precision temperature control, low metal loss, minimal gas absorption and environmental clean skills for melting.

aluminium shell induction furnace:

our factory also have less cost aluminium shell induction furnace, this type furnace with aluminium shell have same melting speed compared to steel frame furnace.

The following are the main components of the aluminium shell induction furnace:

a. High quality aluminium shell cover, looks magnificient and beautiful, the aluminium shell cover has small weight and can be easily installlation and operate, maintenance.

b. easy installation and maintenance for aluminium shell induction furnace set.

c. less cost and same efficiency than steel frame induciton furnace.

d. reducer control automated pouring furnace body.

e. Induction copper coil It is assembled from a solid, durable and highly conductive T2 copper tube. The copper tube is a Chinalco Luoyang Copper Co., Ltd brand product. The water-cooled coil and the effective coil are integrally formed by a copper tube without segmentation. The two adjacent copper tubes of the induction coil are strictly insulated and adopt advanced segmentation technology. An insulating sheet is implanted between adjacent induction coils. After the insulating varnish is sprayed, it becomes a complete structure, and is pressed by the upper and lower steel structures in the furnace body, and the overall structure is firm and has no deformation problem. The coil turns are appropriate to achieve maximum electrical efficiency. The coil is supplied with cooling water from a plurality of water paths and evenly distributed. The outside of the coil is tightly wound with an insulating material. The inter-turn arc-shaped insulating spacers ensure uniform coil spacing and facilitate moisture removal.

f. Reducer

aluminium shell induction melting furnace adopt to use reducer automated pouring furnace body, also can insure totally empty the metal liquid,

Product Items: (Supplied from Luoyang Wanle Electrical Equipment)

| NO. | Quantity | ITEM. |

| 1 | 1 Set | 300KW(One set), 1000HZ output power supply cabinet |

| 2 | 1 Set | Induction melting Furnace body with hydraulic system pouring |

| 3 | 1 Set | Capacitor Assembly bank(Self cooling) |

| 4 | 1 Set | Induction Copper Coil |

| 5 | 2 pieces | Water Cooled Cables |

| 6 | 1 Set | Technical documents, drawings and operation manuals |

| 7 | 1 Set | Necessary spare parts for power supply cabinet |

Supplier system:

The aluminium shell and furnace parts produced by renowned groups in China.

Attachment 1:Power cabinet main components suppliers and some equipment manufacturers.

NO. | ITEM. | SUPPLIERS AND MANUFACTURERS |

1 | Silicon controlled thyristor | TECH SEMICONDUCTORS |

2 | The freewheeling diode | TECH SEMICONDUCTORS |

3 | Main Fuse | Cooper Bussmann |

4 | Resonant capacitor | Xinanjiang power capacitor limited |

5 | Resistance capacitance | Xinanjiang power capacitor limited |

6 | Coil tube T2 | Chinalco Luoyang Copper Co., Ltd |

7 | Copper bar T2 | Chinalco Luoyang Copper Co., Ltd |

8 | Hydraulic pump station | YUCI Haydraulic CO,. Ltd. |

9 | Hydraulic valve station | YUCI Haydraulic CO,. Ltd. |

10 | Stainless steel pump | Shanghai Kaiquan pump (Group) Co., Ltd. |

11 | Main switch for power cabinet | Zhejiang TENGEN |

12 | PLC & HMI | SIEMENS |

13 | Copper tube closed cooling tower | Wanle Eectrical Equipment Plant |

14 | Rectifier transformer | Sanmenxia Sanjin Transformer Manufacturing Co. Ltd. |

15 | Silicon steel sheets | Wuhan Iron and Steel ( Group ) Corp./Baosteel |

16 | Hydraulic cylinder | YUCI Haydraulic CO,. Ltd. |

17 | Emergency diesel generator set | YAMAHA |

Produce control system:

There are Four departments in this manufacturer, one of them charges for assembling furnace body, other charges for KGPS power supply,the third for aluminium shell furnace and fourth for induction heating furnace. All the technical workers have technical certificates who welding and cutting steel plates for furnace body.Mr. Wang is actual president,he knows the technology of intermediate frequency melting furnace and heating furnace, established this company in 1992,and start to research and produce since that year.Every Steel Frame Furnace is designed for its structural strength with the help of experience engineers and specilized workers,so our factory have competitive price induction furnace. And our factory also have less cost aluminium shell induction furnace, this type furnace with aluminium shell have same melting speed compared to steel frame furnace. Our factory have many specilized workers and engineers to make induction furnace rather than only use computer software, so the price is really competitive.

QC System:

The technical person must test the furnace material and parts to ensure its quality.All the melting and heating equipment accordance with national standard strictly in the products produce procedure:

JB4086-85 <Technical Specifications For Electronic Controlled Heating Equipment For Medium Frequency Induction Heating>

GB10067.1-88 <General Part Of Basic Technical Conditions For Electric Heating Equipment>

GB 10067.3-88 <Basic Equipment For Electric Heating Equipment -- Induction Heating Equipment>

GB, 5959.3-88 <Safety Of Electric Heating Equipment, Third Parts, Induction And Conductive Heating Equipment, Induction Melting Special Requirements For Equipment>

GB 5959.1-86 < Safety Of Electric Heating Equipment - Part 1 General Conditions> Environmetal protection standard promised, Melting and heating efficiency of metal confirmed, worker protection mechanism designed.When the melting metal material with no problem,if the foundry efficiency is not the standard as we said,the problem will be in charged and resolved by our side.

Storage system:

The material enough supplied for producing melting and heating equipment, storaged in the place where is dry and normal atmospheric temperature.

Testing system before delivery:

To test the melting and heating function of equipment,or delivery after customers checked the quality.

Packaging System:

The whole equipment finished full and completely covered by container to delivery. The equipment will fixed by our factory in container to prevent damaged by crash in the delivery process.

Small capacity furnace packaged by Plywood Case or as customers's request.

After sales service system:

The engineers overseas service available, the infrastructure prepared by buyers based on drawings supplied by our factory, our engineer will teach the workers to install the equipment and make the equipment works successfully. The training exist in the whole procedure of installing and testing,introduce correct,safe operate and personal protection actions after the equipment operate without any problem.

Our factory mainly engaged in Intermediate frequency electric furnace(heating equipment and smelting equipment).Capacity ranges from 0.15 ton to 40 ton. The company established in 1992 year, as a manufacturer in Luoyang City Of China,has more than twenty-seven years experience of producing electrical equipment. After almost 30 years development, the company upgraded to Henan Rongke Electrical Manufacturing CO., LTD. for opening a new era. Henan Rongke keep up with latest electric induction furnace technologies all the time, 20 minutes once molten with our highest efficiency and have the patent of three rectifier inverter induction stirring melting furnace for alloy casting. Except that Chinese domestic market,smelting equipment also exported overseas. Our factory have steel bars,copper pipe,cast iron and steel mold turn-key project experience in Africa,Southeast Asia and Middle East Area.

The factory refers to and integrates the advantages of medium frequency induction heating equipment at home and abroad. Based on the principle of reasonable structure, advanced technology, practical and reliable, and convenient maintenance, the 50-50000KW medium frequency constant power digital control intermediate frequency heating power supply is compared with ordinary lines. The energy-saving effect is obvious, and the power saving can be about 15%. Since the connection is very small, the failure rate can be reduced to 10%, and the commissioning and maintenance is simple.

Henan Rongke Electrical Manufacturing CO., LTD. is an economic entity registered and established by Luoyang Industry and Commerce Bureau in 1992 with the approval of Luoyang High-tech Industrial Development Zone Administrative Committee. In 1993, it was approved by Luoyang science and Technology Commission as a high-tech enterprise.

Our factory is a professional development, design, manufacture of industrial electric furnace and industrial power equipment enterprises, with strong economic and technical strength, rich design and production experience, thoughtful after-sales service, focusing on the development of induction furnace. Products are widely used in metallurgy, machinery, automobile, aviation, agricultural machinery, hardware and other industries. Through continuous innovation, the company is applying foreign advanced technology to Chinese industrial heating field to improve the technical level of electric furnace in China. The company has strong technical strength, and has a group of experienced and innovative talents.

Factory in year of 1992 New Factory

Contact us:

Mobile: +86 18336778759

Похожие товары

3500 кг металлические алюминиевые банки, плавильная печь, цена

Фетровый пенал для ручек и карандашей, многофункциональные школьные принадлежности, фетровый чехол для карандашей

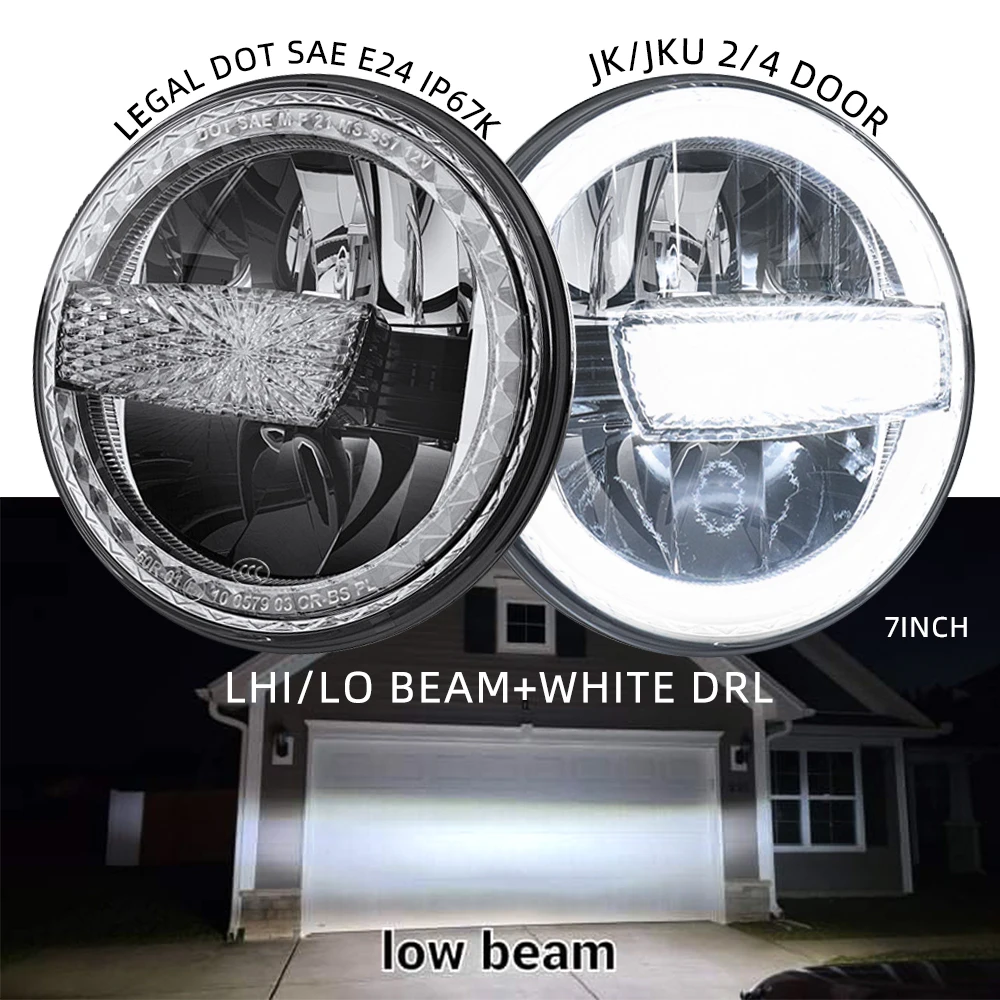

Легальная точка E24 SAE грузовик 4x4 лампа 7 дюймов круглый 40 Вт 12 в 24 В Белый Daymaker Angel Eyes DRL внедорожная светодиодная фара для Wrangler

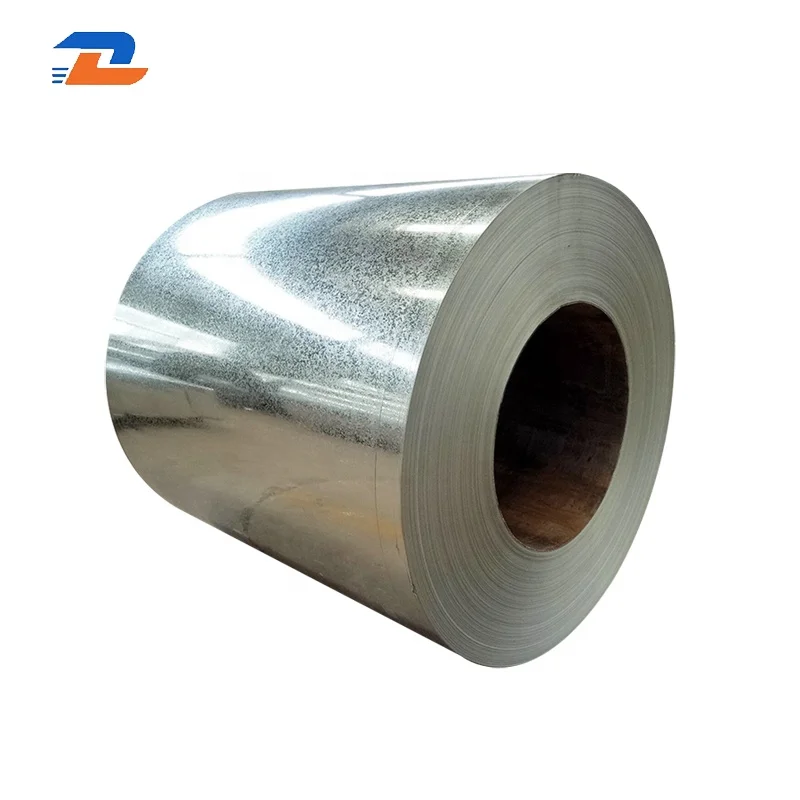

Горячая окунутая катушка gi лист кровельный оцинкованный gi палуба платформы стальная пластина катушки

Лидер продаж 2021, многоразовый фетровый пенал для ручек, чехол, косметички, канцелярские принадлежности, органайзер для ключей, сумка для карандашей

Китайский поставщик, фабрика, индивидуальный дизайн, красочная Студенческая серая, розовая, черная фетровая сумка для карандашей

Новые модные студенческие канцелярские принадлежности из Малайзии, оптовая продажа, высококачественный фетровый пенал на молнии из хлопковой ткани с забавным принтом животных

Новые поступления

Новинки товаров от производителей по оптовым ценам