Большая производственная машина для картофельного крахмала производственный процесс завод по переработке Машина

- Категория: >>>

- Поставщик: Kaifeng Sida Agricultural Products Equipment Limited Company

Сохранить в закладки 62201551495:

Описание и отзывы

Характеристики

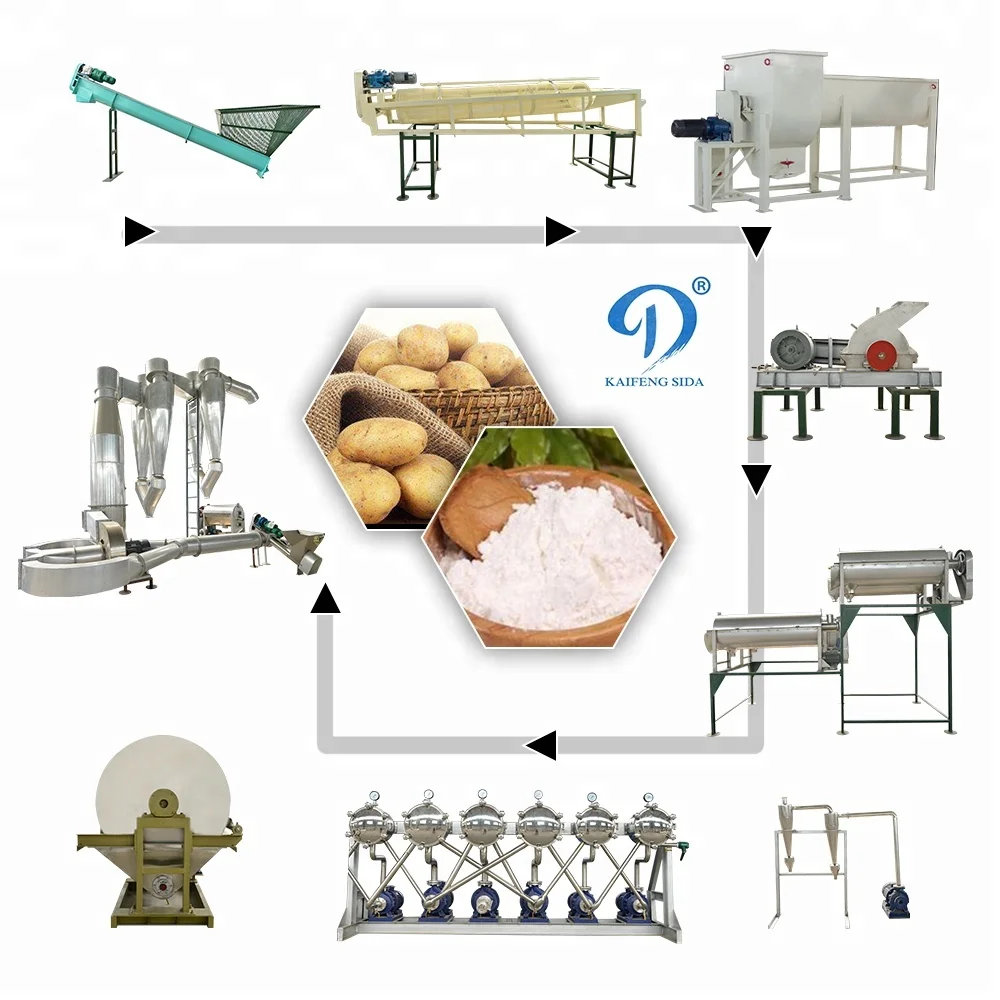

Large potato starch production process

The potato is also called the potatoes, is a more common crops in our lives, in our families, we are usually the potatoes as a food made of life, but in many large grow potatoes, are generally will be processed into starch potato for use by the people, and what is the process of potato processed into starch?Kaifeng sida potato starch processing equipment company to help you answer.

Potato starch production process and sweet potato production process are basically similar, as follows:

1. Cleaning process and equipment

The main material is to remove the surface layer with sediment, and wash away the surface of the material root tuber, stone cleaning machine is to remove the hard impurities in the material.As a raw material for the production of starch cleaning, is to ensure the quality of starch foundation, the more clean, the better the quality of starch.Conveying is to transfer materials to the next process, often conveying at the same time also has a cleaning function.Commonly used transportation, cleaning, stone removal equipment are: hydraulic flow trough, spiral cleaning machine, inclined squirrel cage type cleaning machine, slurry leaf type cleaning machine, stone on the material cleaning machine, (flat) squirrel cage type cleaning machine, rotary drum type cleaning machine, scraper conveyor, etc..According to the characteristics of soil and materials, some of them can be selected for combination to meet the requirements of high cleaning degree and convenient transportation.

2. Raw material crushing and equipment

The purpose of crushing is to destroy the structure of the material, so that the small starch granules can be successfully separated from the root tuber.Crushing requirements are:

1. As far as possible, break the cell of the material, and release more free starch granules;

2. Easy to separate.It is not expected that the residue is too fine, which is not conducive to the separation of starch and other components, and also increases the difficulty of separation of fine residue.

3. Screening process and equipment

Starch extraction, also known as slurry separation or separation, is a key link in starch processing, which directly affects the extraction rate and quality of starch.The crushed material is fine fiber, the volume is larger than the starch granule, the expansion coefficient is also larger than the starch granule, the specific gravity is lighter than the starch granule.

4. Washing process and equipment

Starch washing and concentration are accomplished by means of a starch cyclone, which is divided into a concentrated cyclone and a refined scrubbing cyclone.After sifting, the starch slurry first passes through the concentrated cyclone, the bottom flow enters the scrubbing and refining cyclone, and finally reaches the product quality requirements.The equipment is equipped with a full set of automatic control system, and adopts high quality cyclone tube and optimized drainage scheme, which can make the concentration of starch emulsion removed by the last stage cyclone reach 23Be', which is the ideal choice for starch washing equipment.

5. Starch dehydration

Potato starch often adopts vacuum suction filter and dehydrator.Can achieve automatic feeding, automatic dehydration, automatic cleaning.

6. Starch drying

Airflow dryer is the use of high-speed flow of hot gas to make wet starch suspension in which, in the process of airflow drying.It has the characteristics of high heat transfer coefficient, large heat transfer area and short drying time.

7, starch cooling and sieving packaging

Starch after drying, the temperature is higher, in order to ensure the viscosity of starch, starch needs to be rapidly cooled after drying.After cooling the starch into the finished product screen, in order to ensure the fineness of the product, the output of the premise into the final packaging process.

Above is the process of making potato starch, kaifeng is a professional potato starch processing equipment manufacturers, with more than 20 years of experience, there is a need for this aspect, welcome to consult.

Похожие товары

Usx2064 Usb 2 0 высокоскоростной 4-портовый концентратор контроллер 36-контактный Vqfn T/R микросхема

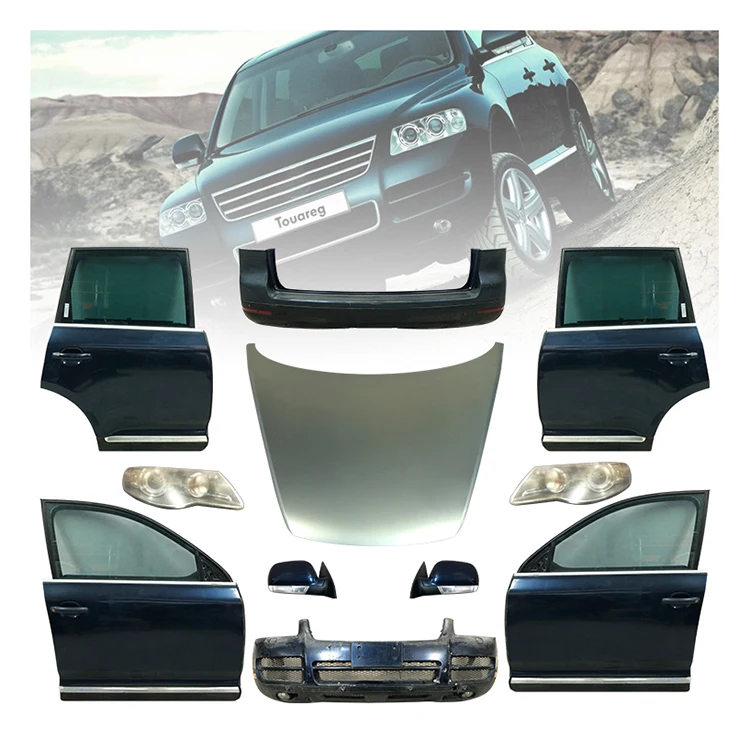

2006 немецкого автомобиля используемые части подержанных автомобилей запчасти Подержанный автомобиль запасные части 《 Volkswagen toouareg

Большой многопролетные парниковая пленка

Китайская дешевая Шахматная форма для шахматных

Лидер продаж вкусные жареные нарезные тофу здоровые соевые

Американская кабельная ветвейная коробка 10 кВ Высоковольтная металлическая распределительная коробка с одним в тремя выходами

Максимальная мощность 800W * 4 четырёхколёсный вагончик с диск ANZO-A9 углепластиковый Электрический емкость батареи 10S3P (18650)

Новые поступления

Новинки товаров от производителей по оптовым ценам