Бизнес план по производству корма для животных кормовая система ячменя водная линия переработке

- Категория: >>>

- Поставщик: Jinan Shengrun Machinery Co. Ltd.

Сохранить в закладки 62219448297:

Описание и отзывы

Характеристики

Animal Feed Production Business Plan Barley Fodder System Aquatic Feed Processing Line

1. Processing line introduction

This processing line is mainly made up with raw materials treatment system, extrusion system, drying system, flavoring system and controlling system. It has high stability and automatic performance, which offers the possibility to control the expansion of the extrudate through various means to control the texture of the final product.

2. Processing line description

2.1 Flow chart: raw materials→ extrusion→ drying→ flavoring→ cooling→ packing

2.2 Processing line features

2.2.1 High work efficiency, automation degree, materials usage, application range.

2.2.2 Low land occupation, power consumption, labor cost, waste rate.

2.2.3 Various configurations and capacity choices.

2.2.4 This processing line can make both floating and sinking fish feed. It can make pet food as well.

2.2.5 Production factors can be quantified and controlled.

2.2.6 World-class food grade fittings.

2.2.7 All machines and fittings can be custom-made. ODM/OEM is available.

2.2.8 Professional pre-sale, sale and after-sale service.

2.3 Processing line parameters

Type | Model | Capacity (kg/h) | Installed Power (kw) | Actual Power (kw) |

Dry | TSE65-P | 100-150 | 74 | 52 |

TSE70-P | 200-250 | 105 | 75 | |

TSE85-P | 300-500 | 205 | 150 | |

Wet | TSE90-P | 800-1000 | 132 | 80 |

TSE95-P | 1000-1500 | 165 | 106 | |

TSE120-P | 2000-2500 | 226 | 140 |

2.4 Machines and fittings graphic introduction

2.4.1 Series extruders

2.4.2 Series dryers

2.4.3 Fittings

2.5 Manufacture process

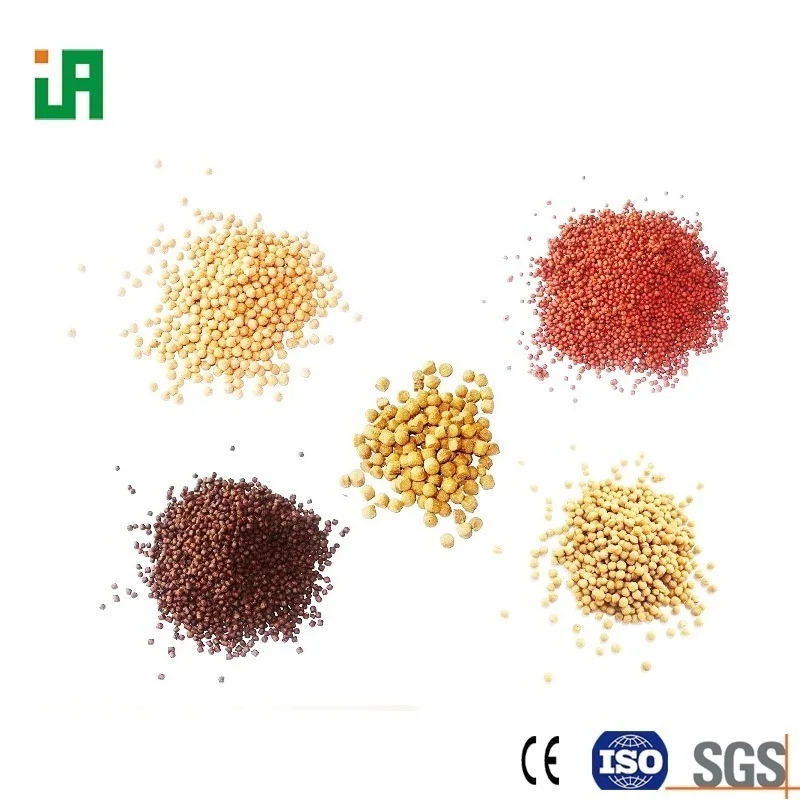

3. Fish feed introduction

In order to meet modern fish farms development, most of modern fish feed is made by twin-screw (or single screw) extrusion production line, which is called expanded, extruded or puffed fish feed. Adopting cereals, vegetable proteins, vitamins, minerals, fish meal and fish oil as raw materials, and adopting dry-type or wet-type extrusion as manufacturing technique, expanded fish feed is made for both carnivorous and graminivorous fishes. Compared with traditional fish feed, expanded fish feed has the advantages: (1) easier feeding management (2) lower wastage rate (3) lower water contamination (4) higher feed nutritional ingredient use ratio (5) longer storage time. Expanded fish feed improves digestibility and refined the balance of nutrients to match the needs of the different species of fish more precisely at different periods of development. At the same time, expanded fish feed improves the sustainability of the ingredients used. Based on the advantages, expanded fish feed will replace traditional fish feed in the future.

4.1 Inside package is plastic film, outside package is wooden/plywood cases, which is seaworthy.

4.2 We can supply fumigation package and certificate.

5. Service

5.1 1 year warranty period.

5.2 Supply free fittings and general tool.

5.3 Engineers available to service machinery overseas.

5.4 Supply formula of raw materials.

5.5 Workshop design suggestion.

6. Company introduction

Jinan Shengrun Machinery Co., Ltd. is Chinese leading expanded food machinery manufacturer in China.

We can design and manufacturer the machines to make expanded food for human and animals.

So far, we have 3 factories, which covers 5000 square meters. We have ISO9001:2008 & CE certificate, and pass SGS, BV & TüV inspections. We have exported our machines to more than 60 countries in the world and keep development.

Q1: Are you manufacturer or trader?

A: We are manufacturer.

Q2: Could you supply customized machines?

A: We can supply customized machines based on your requirement. By the way, ODM & OEM are available for us.

Q3: Can you supply oversea service or food formula?

A: Our engineers can serve you in your factory, and we can supply formula.

Q4: Could I only order stand-alone machine (e.g. only extruder, dryer etc.)?

A: Yes. We can not only supply processing line, but also stand-alone machine.

Q5: Where are you? How can I get there?

A: We are in Jinan, which is in the North of China, 432km South to Beijing. You can go to Jinan by high speed train (Jinan West Station) or by air.

Q6: Have you ever sold your products to International market?

A: Until 2015, we have sold our products to more than 60 countries and regions. This number is keeping growing.

Q7: How can I get the after-service?

A: We will send you the spare parts by free if the problems caused by us. If it is the men-made problems, we also send the spare parts, but you should pay for it.

Q8: Could you supply food raw materials or the machine in different industry?

A: Because of the business scope limitation in China, we can only supply food machines. But we can help you to find the best suppliers in China. As Chinese, we are more familiar with Chinese market.

Need more details? Feel free to contact us!

Похожие товары

Система выращивания без земли для гидропоники/раствор для выращивания корма кукурузы для выращивания корма скота

Многофункциональная 3D вышивальная машина PROMAKER, 15 игл, 1 головка, промышленное кожаное полотенце для шляп

Многожильная машина для скручивания пряжи/машина для скручивания шелковой пряжи

Атлас летнее платье с длинным рукавом для женщин пижамный комплект изготовление штампованой бумаги под заказ Шелковый OEM сервис двойка длинный 100% полиэстер сплошной крашенная в пряже поддержка

Разноцветная шелковая лента sari, пряжа из переработанной шелковой ткани sari, подходит для магазинов пряжи и волокон

Высококачественный чистый шелк «TSUMUGI ITO»

KC259-380 начальных и retwist «Все-в-одном» шелковой пряжи переплетая машину для промышленная пряжа

Новые поступления

Новинки товаров от производителей по оптовым ценам