Высококачественный полиэфирный ПЭТ высокопрочный Спиннинг для

- Категория: >>>

- Поставщик: Cissco Machinery Co. Ltd.

Сохранить в закладки 62225916202:

Описание и отзывы

Характеристики

Polyester PET High Tenacity Yarn Spinning Machine

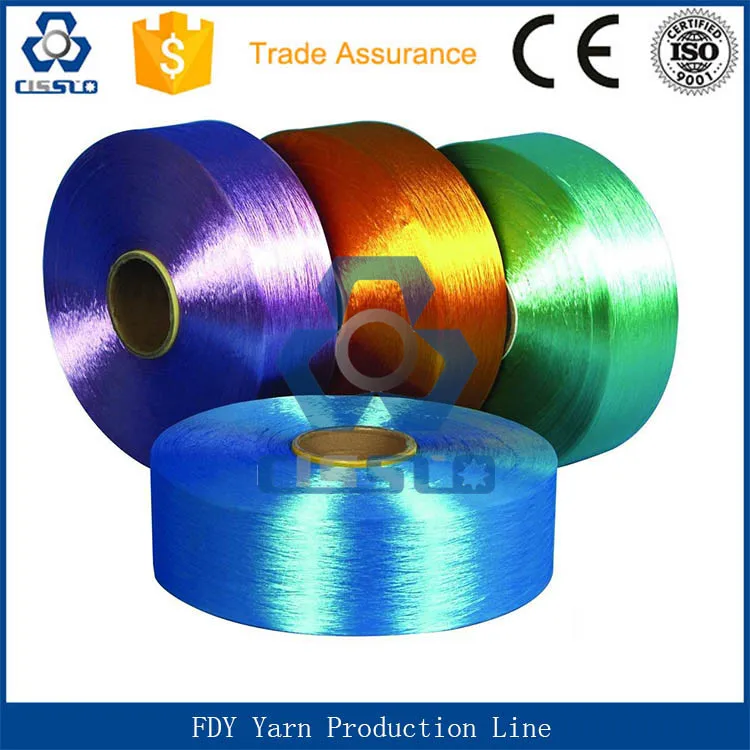

FDY is commonly known as the Fully Drawn Yarn. PP FDY is used for manufacturing the fabric and and lace, also sewing thread. We supply FDY with the range of 300-1200 denier.

1. Production Process of Machine

Used for producing PP FDY by processing of extruding, melting, spinning and drawing ,consisted of spinning machine ,drawed-winder

Process:

Chips→ extruder→ extruding head→Filter→melt pipe with static mixer→ spinning beam with oil heating →quenching delay→ quenching chamber → oiling system → feeding roller →migration nozzle→ Five pairs of hot godet→interlacing jets→ take-up winder → final product

Efficiency

600de:900×2200×8×1440 ×0.95 =1.2ton /day

9000×1000×1000

300de:400×2200×8×1440 ×0.95 =0.8 ton /day

9000×1000×1000

2. Technical Parameters of Machine

| ITEM | Main technical data | |

| No. of positions | 1 - 8 | |

| Denier | D | 300-1200 |

| Melt pump | Cc/rev | 6, 8 & 24, 30 |

| Height of quenching | mm | 1200, 1400 |

| Gauge | mm | 1250, 1350, 1400 |

| Size of screw | mm | Dia 105, 120, 135, 150 |

| Dia of spinneret | mm | Dia 75, 80, 85 |

| Winder no. | sets | 1 |

| Ends (heands) per winder | units | 4, 6, 8, 10, 12, 16 |

| Size of godet | mm | Dia 105 |

| Winding speed | m/min | 3800-4800 |

| Winder type | unit | SWA1260, SWA1380, SWA1500, SWA1680 |

3. Pictures of Machine

• We design, engineer and manufacture and customized the production line for every customer.

• Choosing the right solution: In plastics manufacturing, process is everything. We carefully evaluate each project's requirements, weigh the options and recommend the best solution for the client.

• Training & Development: we offer extensive start-up assistance, comprehensive training. As well as Engineers for training and installation at our client’s factory

• Support: We support the client in all the stages of the project life cycle, as well as the constant spare parts supply in a time efficient manner.

CissCo Machinery Co., has been engineering and manufacturing a series of EXTRUDing MACHINERY for more than 20 years and has acquired an extensive expertise in the supply of manufacturing machinery; having based ourselves on the features demanded by large companies in more than 30 countries.

MONA

Whatsapp/Wechat:+86 189 1832 1292

Skype: +86 158 2172 2692

Add: No. 58, New Jinqiao Road, Pudong New Zone, Shanghai, China

Spinning Machine Spare Parts

Похожие товары

Специализируется на производстве водных лыж детская переноска с двумя сиденьями высокоскоростной лыжный реактивный видов спорта водные лыжи для

Оптовая продажа из Китая в твердом переплете Y-O вязка изготовленный на заказ журнал Книжное производство

Копировальная бумага A4 100% целлюлозы 80 г/кв. М Svetocopy 75 70 оптовая продажа копировальная машина для ежедневного использования

2023 новейший дизайн 3d led бездна зеркало неоновое абиссальное волшебное зеркало

Светодиодная лента для телевизора светодиодная подсветки LGE 19Y 49 дюймов _ l-type r-type 49SM8600PUA 49NANO85UNA 49SM8200PLA

Качающийся трехколесный велосипед EEC 2000 Вт 2*60 в 20 Ач скутер с аккумулятором для взрослых citycoco 45 км/ч электрический

Корпус фильтра для химической или водяной рециркуляции, раствор гальванического покрытия печатной платы, гальваническое покрытие

Новые поступления

Новинки товаров от производителей по оптовым ценам