API 8C ручной инструмент сверлильный Лифт на продажу

- Категория: >>>

- Поставщик: Dongying Kangya Petroleum Equipment Co. Ltd.

Сохранить в закладки 62232893055:

Описание и отзывы

Характеристики

Product Application

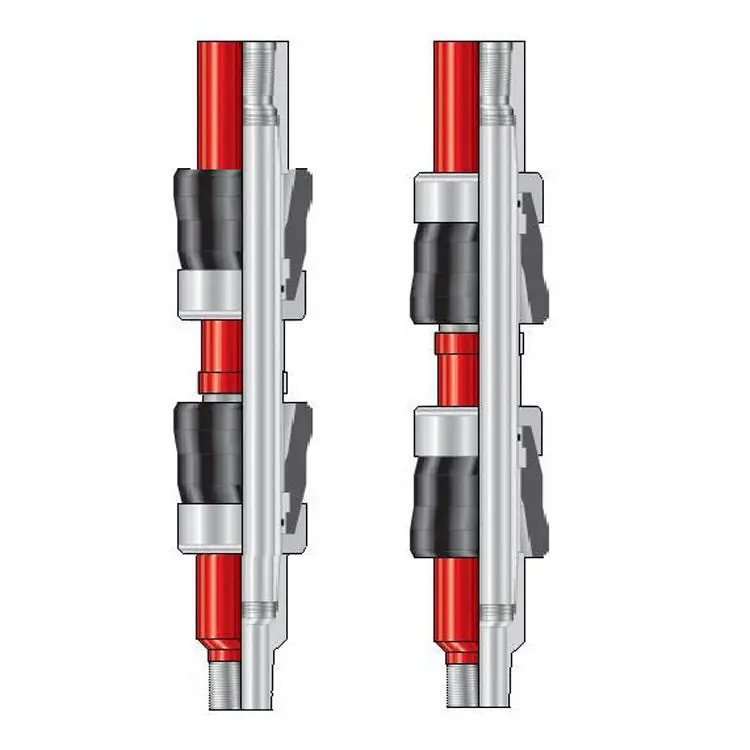

DH forged elevator links are designed to hang elevators from Top Drive System or Hooks in drilling operation. Read the Manual before use elevator links.

Each elevator link of one pair is forged from one single billet of high strength alloy steel, heat treated, surface-strengthen treated and NDT for super performance

and long service.

The rating loads of elevator links series are

150t(1350kN),200t (1800kN),250t (2250kN),350t (3150kN),500t (4500kN).

All the technical data and properties of elevator links completely conform to the requirements of SY/T 5035 and API Spec 8C.

Structural

Elevator links can work in pairs. The elevator link upper eye is used for the hook link ear, and the elevator link lower eye is used for the elevator.

Specifications for DH forged elevator links

Chart for specifications of DH forged elevator links:

specifications | Rating loads | Length | ||||||

US ton | kN | cm | in | |||||

DH 150 | 150 | 1335 | 180 | 71 | ||||

DH 200 | 200 | 1780 | 270 | 108 | ||||

DH 250 | 250 | 2225 | 270 | 108 | ||||

DH 350 | 350 | 3115 | 330 | 130 | ||||

DH 500 | 500 | 4450 | 360 | 142 | ||||

Note:①1 US ton≈8.896kN ② The elevator links of the specifications in this chart are manufactured by our company, other specifications our customer required can be defined in contract. | ||||||||

Perfection link

Description

SH dependable, efficient perfection links are designed for light loads.

Perfection links are made by forging, bending and electric welding of high-quality steel bar stock, which is then heat-treated and NDT examined. Rating loads of perfection links series are 50t (450kN), 75t (675kN), 150t (1350kN).

All the technical data and properties of perfection links completely conform to the requirements of SY/T 5035 and API Spec 8C.

Structural

Perfection links can work in pairs. Bigger end of perfection link is for the hook link ear, and small end is for the elevator.

Specifications for SH Perfection Links

Chart for specifications of SH Perfection links:

Specifications | SH 50 | SH 75 | SH 150 | |||

Rating loads | 50t(450kN) | 75t(665kN) | 150t(1335kN) | |||

Length | 1100mm | 1500mm | 1800mm | |||

Note:①1 US ton≈8.896kN ② The elevator links of the specifications in this chart are manufactured by our company, other specifications our customer required can be defined in contract. | ||||||

Dongying Kangya Petroleum Equipment Co.,Ltd.is a professional manufacturer and supplier of all types of petroleum equipment.The company is located in Dongying, the beautiful petroleum city at Yellow River Delta, covers an area of more than 330 million square meters.

And we have many years of history in the petroleum equipment industry.Our main products include drilling equipment,oil production equipment,wellhead equipment,well control equipment,downhole tools,OCTG pipe,\tvavle & pipe fitting and oilfield tools.

Currently,our products is already exported to America, Middle East, Australia,Africa and 20 other countries and regions.

Our company has always focused on research, development and innovation.Kangyapetro will initiate the second phase of our development strategy.Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

1) How can I place order?

A: You can contact us by email about your order details, or place order on line.

2) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T and Western Union are the most usual ways we are using.

3) What's the order procedure?

A: First we discuss order details, production details by email or TM. Then we issue you an PI for your confirmation. You will be requested to do pr -epaid full payment or deposit before we go into production. After we get the deposit, we start to process the order. We usually need 15-25days if we don't have the items in stock. Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

4)How do you take care when your clients received defective products?

A: replacement. If there are some defective items, we usually credit to our customer or replace in next shipment.

5)How do you check all the goods in the production line?

A: We have spot inspection and finished product inspection. We check the goods when they go into next step production procedure.

DD elevator

100% Response Rate

SLX elevator

100% Response Rate

CDZ elevator

100% Response Rate

Похожие товары

Новое Карбидное алмазное сверло PDC Для Добычи Руды и угольного вогнутого бурового долота кованый Буровой инструмент

16-дюймовые кованые твердосплавные сверла для строительства и бурового оборудования для водяных скважин, используемого для стального бурения

Буровая труба JT25 HDD

24 Вт горнодобывающие сверла, новый инструмент для ковки из карбида вольфрама, 6 месяцев, цена

API 11D 7 дюймов, упаковщик с двойной чашкой, ковка, сверлильный инструмент для бурения скважин

Новая твердосплавная коническая штанга из углеродистой стали для Добычи Руды, Бурильная труба 30 мм для строительства, кованый Буровой инструмент

Новая кованая буровая труба из углеродистой стали

Новые поступления

Новинки товаров от производителей по оптовым ценам