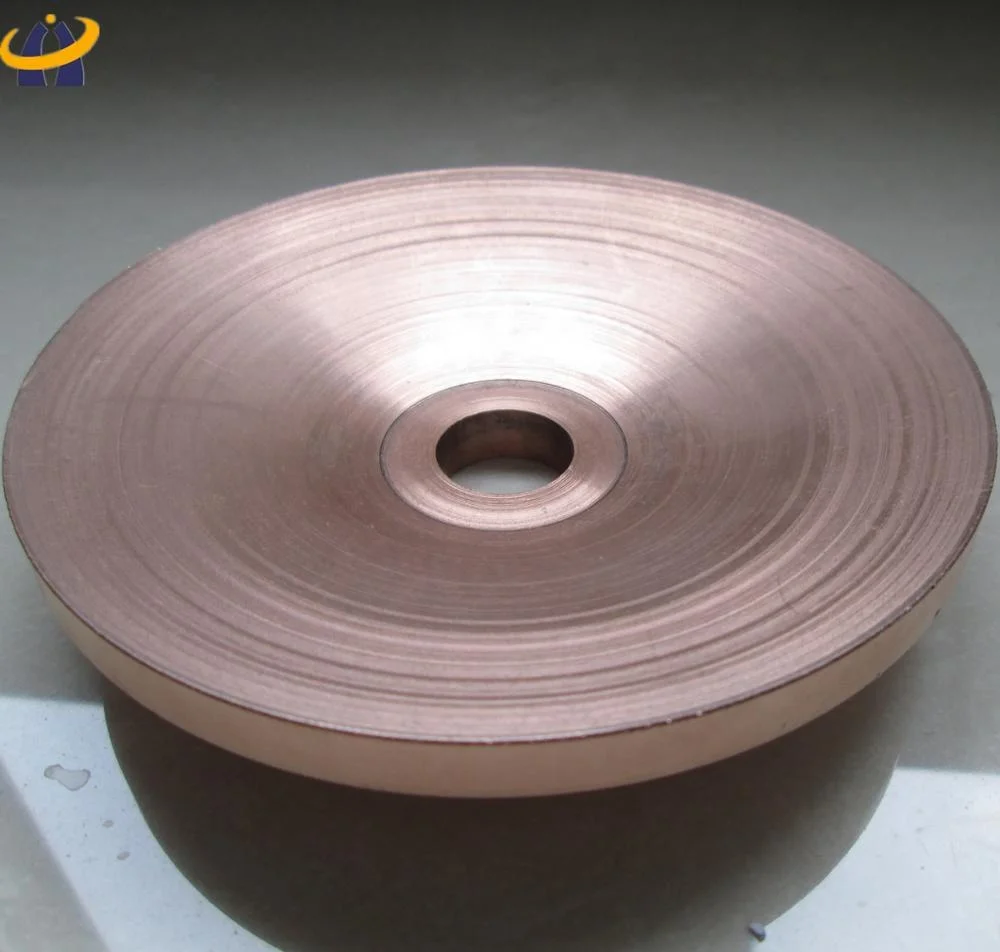

Медное вольфрамовое параллельное сварочное колесо

- Категория: >>>

- Поставщик: Changsha Mingguan Metal Technology Co. Ltd.Changsha Ltd.

Сохранить в закладки 62242917878:

Описание и отзывы

Характеристики

Tungsten copper welding cup wheel,tungsten copper welding wheel, copper tungsten welding electrode

Introduction

Tungsten copper welding wheel is also called rolling welding wheel, which is a kind of electrode wheel mounted on seam welder. Due to its good wear resistance, electrical and thermal conductivity can be widely used in steel, stainless steel, copper, aluminum and other materials welding.

Principle

Seam welder is similar to spot welder, but there are some differences in the shape of elctrode. The electrode of spot welder has rod-like electrode and spark welding, but the seam welder has two upper and lower ring-like electrodes and continuous or intermittent dischargeing. Tungsten copper welding wheel is suitable for the continous welding in metal sheet joints, such as soldering iron tin cans. In the welding process, upper and lower ring-like electrodes clips the welded workpiece, the welding wheel plays a part of electrode and were released by being positive and negative current welders, welders are in contact so that the heat generated will be fused welder parts. And the rotation of the roller drives welders to form a continuous welding process.

Comparison

At present, common materials used for welding wheel mainly includes tungsten copper, beryllium copper, and cobalt chromium zirconium copper. All of three kinds materials have high hardness, excellent performance in electrical and thermal conductivity, wear and corrosion resistance and creep resistance. But there are some differences in the manufacturing process and applications among them. Beryllium copper, cobalt and chromium zirconium copper generally use vacuum casting - hot forging - solution technique - cold forging fight - the heat treatment process, while tungsten copper materials are mainly used infiltration sintering method. In applications, beryllium, cobalt and copper weld wheel is more suitable for carbon steel, wire, stainless steel wire and having a larger pressure to the top of the workpiece welding; chromium zirconium copper welding wheel is suitable for low-carbon steel, steel, wire welding; tungsten and copper is more suitable for welding with silver, copper, aluminum, stainless steel mesh, barbed wire and other materials.

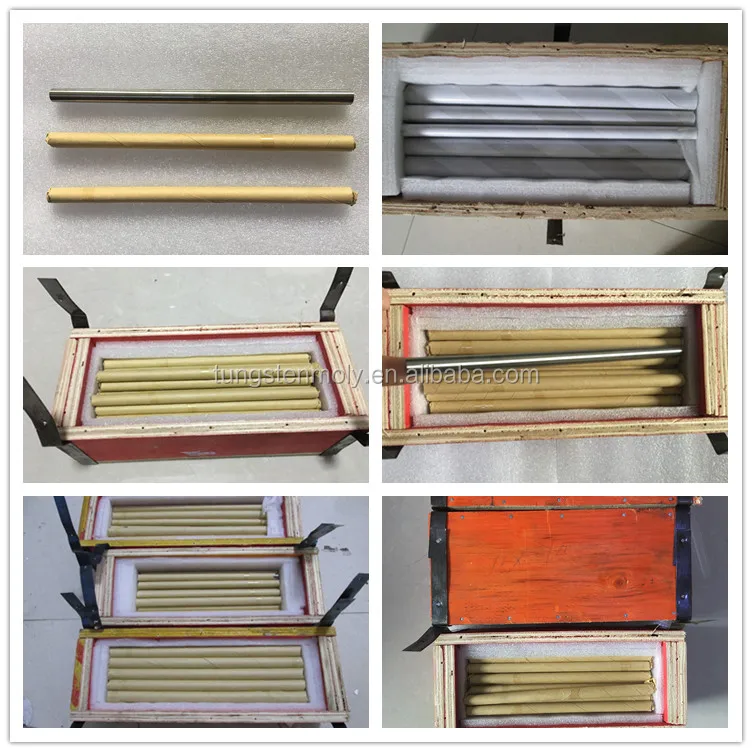

Packing Details :

Inner package:paper or plastic bag or sealing bag,PE foam,

Outer package:thick carton or wooden box or iron drum

Delivery Details : 3-30 days after order ,express by DHL,TNT,UPS,SF etc. door to door.

Package sample as below, we will use difference pack method as difference products :

High quality and competitive price , years of experience factory directly supply.

Supply difference maching parts ad drawing for customer, with fast delivery.

24 hours online service, answer question , quote , best after-sales service.

Changsha Mingguan Metal Technology Co.,Ltd has advanced technologies,superior machines&equipment, state-of-the art testing instruments and modern workshops.It also has established a set of scientific ,management system and strict quality control system. MingGuan ensures all the aspects of development(design),production, sales and services to comply with the highest international standard or design and manufacturing excellence.

Equipment Section and producing department:

Talk face to face in office

Confirm the order in factory

On the Material Fair

Q: Why should I choose your company for partner?

A: As you know, the raw material of low price makes your product more competitive in the market. That means it will make your sell much easier.

Q:Do you use first class tungsten /molybdenum powder?

A:We only use first class tungsten / molybdenum powder,no recycle.

Q: Delivery tungsten alloy products can be shorter?

A: Usually we make sure all the order delivery with 30 days.Tungsten copper 15 days.

Q:Price can be cheape?

A: We use first class tungsten powder,the cost is high.

Q:Tungsten /Molybdenum products MOQ?

A:Please email to inquiry per different products.

Q:Tungsten /Molybdenum sample?

A:Sample available,within 7~14 days.

Welcome send us your drawing ,We not only produce the standard types, but also the tungsten/molybdenum/tungsten copper/tungsten carbide parts based on your designs. We have rich experience on this and a big part of our product is from our clients' designs. We can provide the technical support, like how to select the right grade of tungsten to match your using purpose, we will make it very easy and simple to do business with us:

Похожие товары

Сварочные стержни E8016-B2H4 термостойкого стального электрода E5516-1CM низколегированный стальной электрод

2 lantanated Tig сварочные вольфрамовые электроды

Высокое качество Rutle-целлюлозный электрод натриевого типа E6010 стальной сплав Aws A5.1 E7018

5% AG 2 4x500 мм 5 кг серебряный припой Phos медный паяльный сплав круглый стержень BCuP-3 CP104 CuP279 для кондиционера холодильника HVAC

Серебряные сварочные паяльные материалы китайская заводская цена Серебряный паяльный стержень для меди никеля

5% AG 2 0x500 мм 5 кг серебряный припой Phos медный паяльный сплав круглый стержень BCuP-3 CP104 CuP279 для кондиционера холодильника HVAC

Qixing лидер продаж bcup-2 медные стержни для сварки кондиционеров

Новые поступления

Новинки товаров от производителей по оптовым ценам