Энергосберегающая электрическая огнеупорная печь хорошего типа мощностью 75

- Категория: Промышленные печи >>>

- Поставщик: Wuxi Wondery Industry Equipment Co. Ltd.

Сохранить в закладки 62244151246:

Описание и отзывы

Характеристики

Product Application

Pit Type Heat Treatment Electric Quenching Furnace is used for annealing and spheroidizing heat treatment of metal wires, steel coils and alloy wires. The furnace is suitable for heat treatment 1200℃ such as high temperature annealing other heat treatment process.

PID Control Power Adjustable Wire Electric Annealing Oven Furnace

SPECIFICATIONS FOR Pit Type Heat Treatment Electric Quenching Furnace | ||||||

Temperture contral system | Rated Temperature | ℃ | 1200 | |||

Heating element | 0Cr27AL7Mo2 (Iron chromium high temperature strip) | |||||

Furnace body exterior temperature | ℃ | ≤ 45 | ||||

Temperature control system precision | ℃ | ≤±1.5 | ||||

Uniformity of furnace temperature | ℃ | ≤±10 | ||||

Power Consumption | kW | 75kW+10% (1-100% adjustable) | ||||

Muffle Effective Working Size | mm | Ø1000×1000mm | ||||

cover lifting method | up-down by electrical screw | |||||

Temperature Control Method | SCR, PID control, Intelligent temperature controllor, over temperautre alarm and timing function | |||||

Mechanical system | heating area | four sides of furnace hearth+ the furnace bottom | ||||

lining material | refractory fiber for wall and cover; heavy refractory bricks for bottom; | |||||

Main Features

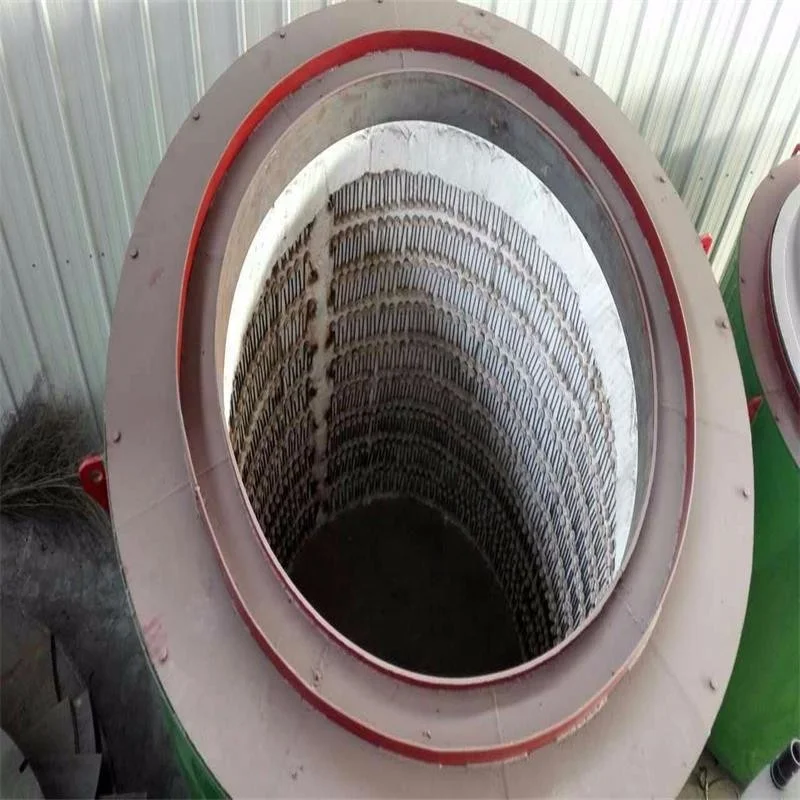

Pit Type Heat Treatment Electric Quenching Furnace is comprised of furnace body, furnace cover, heating elements, electric control system and temperature automatic control system.

furnace shell: The furnace shell is made from 10# ~12# sectional steel and the furnace bottom plate thickness is

6mm .

Lining: The furnace lining is all fiber structure which are fixed to the furnace body by stainless steel

fixtures. The total lining thickness is 320mmm, including 300m pre-compressed fiber block and 20mm

backer cotton.

Heating element: The furnace employs quality 0Cr27AL7Mo2 high temperature alloy belts as heating elements. The

heating element is retained to the furnace wall through porcelain nails.

Furnace cover: The furnace cover is made of 12# U-steel and 6mm steel plate. The heat preservation material adopts

aluminum silicate fiber compression block and it was fixed by stainless steel pieces. The opening

method of the furnace cover is by crane. The furnace cover is sealed by sand.

Muffle tank: The muffle tank is made from 8mm 321 stainless steel plate. It is placed in the furnace hearth. The

cover and bottom of the furnace body are both pressed into shape. The upper part of the furnace body issurrounded by a stainless steel sand sealing groove. And there is an all fiber furnace cover outside the

furnace body so as to form double insulation and seal. So that the energy saving and prevent oxidation

effect has been improved greatly.

cooling is needed, open the thermovents and the fan so that the air could flow in the furnace, and the

furnace could be cooled down fast.

over-temperature alarm. The audible and visual over-temperature alarm would be activated if one

zone temperature is over the limit.

NO. | Item | Q'ty | Remark |

1 | Furnace body | 1 set | Including bottom hearth plate |

2 | 321 stainless steel muffle tank | 1 set | Including stainless steel muffle tank cover |

3 | Heating elements | 1 set | Electric resistance strip |

4 | Temperature control system | 1 set | Including 1 piece temperature controller |

5 | Control cabinet | 1 set | |

6 | SCR | 3 sets | |

7 | Compensating lead wire | 20m | |

8 | Thermal couple | 1 pc | Ktype 0-1300 |

9 | Electrical components | 1 set | Contactor, air switch, ampere meter, voltmeter, thermal relay, switches. |

2. What information should the customer provide to get an accurate quotation from us?

The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc.

3. What is the payment term?

The payment term is 40% down payment, and 60% before delivery (T/T mode).

4. What is the delivery time?

The delivery time of the machine is 15-30 days after receipt of down payment.

Похожие товары

Горячая Распродажа CE сертифицированная 4000 кг Емкость дизельное масло гидравлическая наклонная Алюминиевая Плавильная роторная печь

Высокопроизводительная газовая Вращающаяся печь для плавления порошка свинца

Индукционная чугунная печь из Китая с системой контроля температуры

Среднечастотная индукционная плавильная печь стальной лом железо Купер плавление перерабатывающая машина плавильная печь

Медная кастинговая печь, медные стержни, изготовленные из сброса меди-печи

1000 градусов по Цельсию, газовая печь с подогревом

Экологически безопасная Вращающаяся печь для активации угля

Новые поступления

Новинки товаров от производителей по оптовым ценам