Заводская цена 50 кг машина для упаковки частиц кварцевой смолы песка

- Категория: >>>

- Поставщик: Zhengzhou Jiayu Machinery Equipment Co. Ltd.

Сохранить в закладки 62244338851:

Описание и отзывы

Характеристики

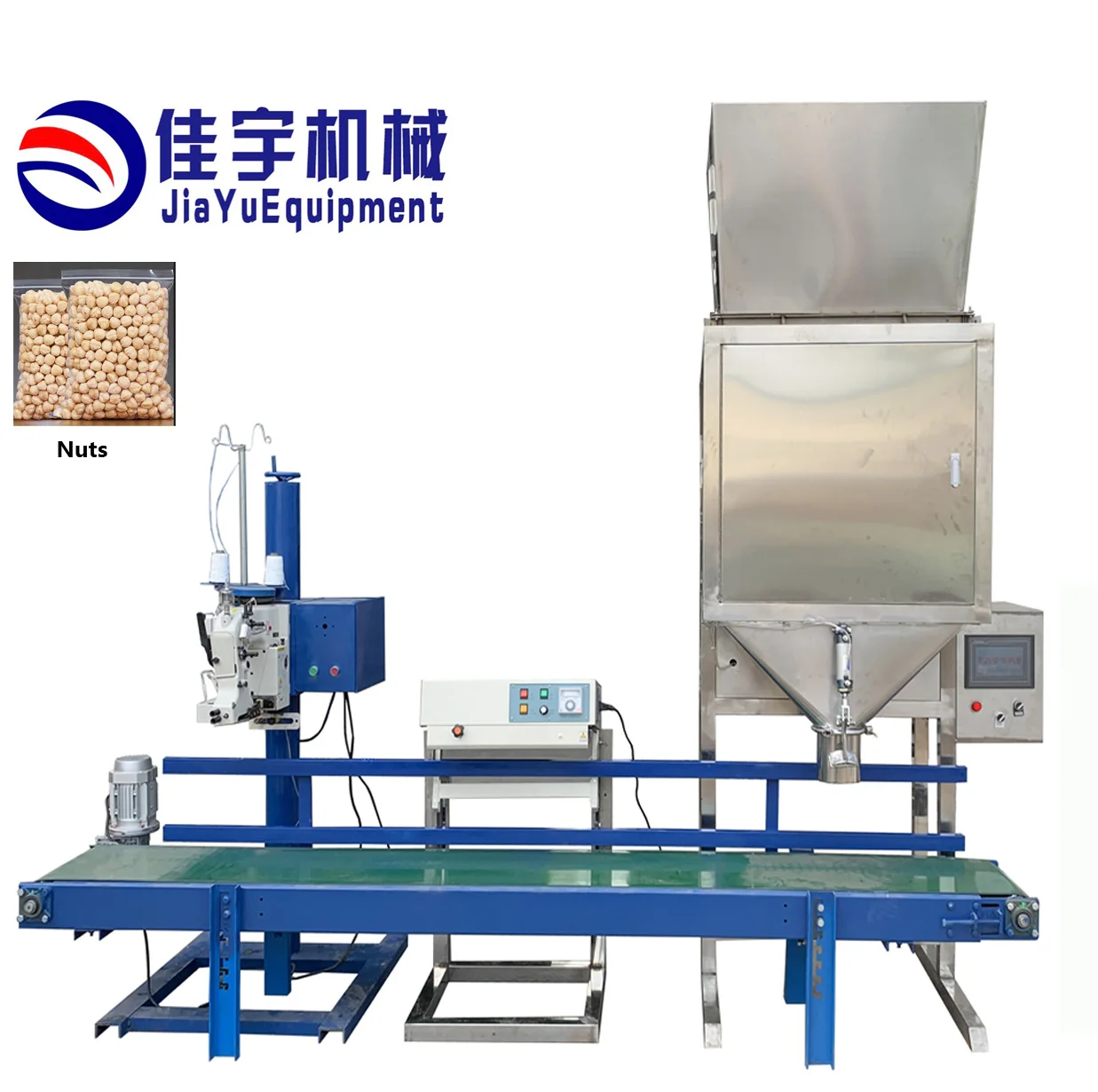

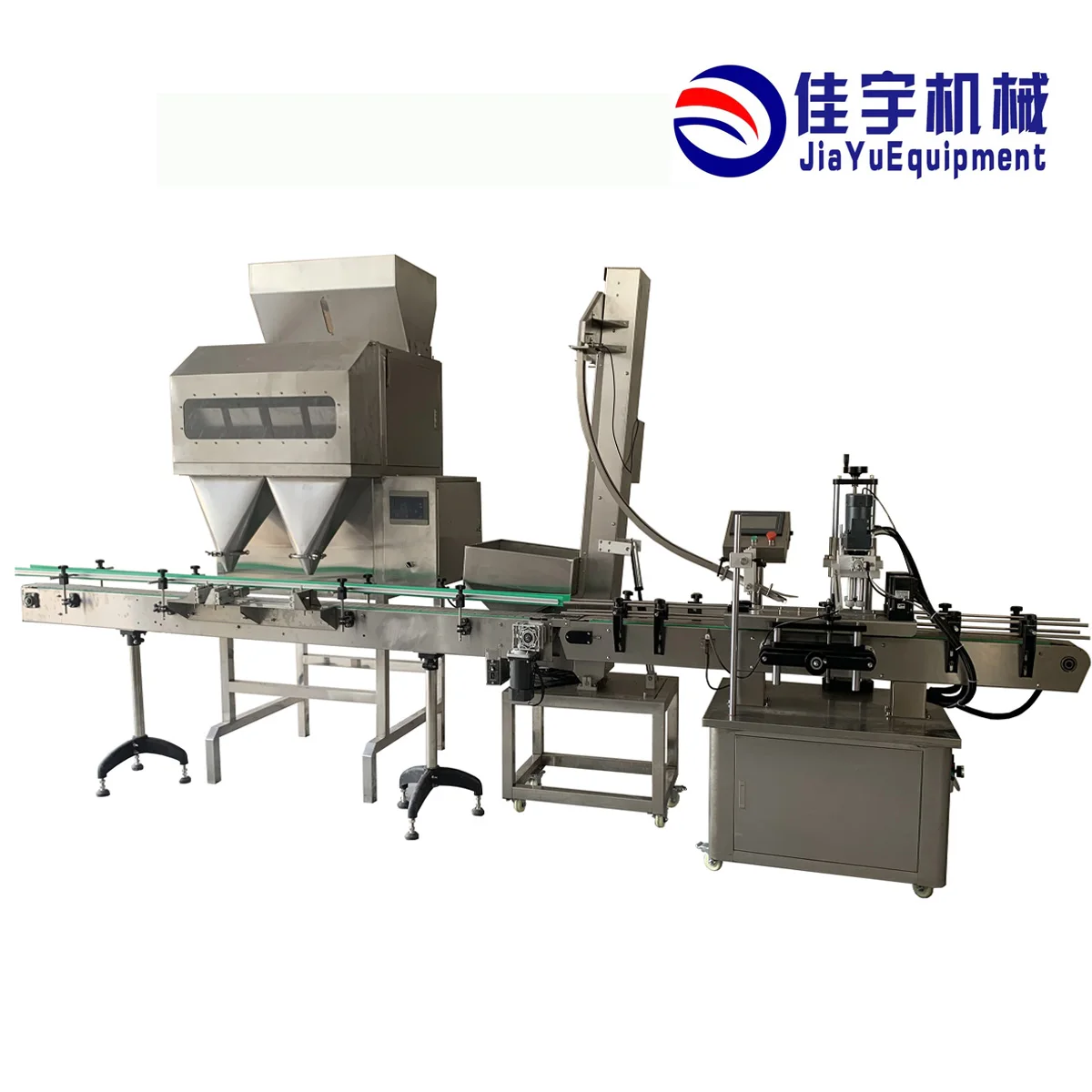

Factory price 50kg quartz resin sand particles packaging machine

Zhengzhou Jiayu is a professional manufacturer of packaging machines. Its main products include granule packing machine, powder packing machine, automatic quantitative packing scale, automatic filling machine, packaging production line, etc. It is widely used in agriculture, food, medicine, chemical industry and daily necessities and other industries. Our company has excellent staff, advanced technology, sophisticated equipment and strict management.

Factory price 50kg quartz resin sand particles packaging machine

The packaging machine is suitable for packaging granular materials with good mobility such as rice, beans, corn, plastic granules, desiccant, blended fertilizer granules, rapeseed, etc.

Host Control:

Function: electronic sensor weighing, PLC weight display control.

The material in the auxiliary silo is transported through the vertical trough. The advanced digital frequency conversion technology is adopted the fast, medium and slow three-speed feeding mode is adopted to ensure that the particulate matter is not leaked. The vertical trough is designed with a sandwich set to ensure the maximum material. The material produced when falling into the packaging bag is reversed through the interlayer, and then falls into the packaging bag by the gravity of the material itself, so as to prevent the material from escaping into the atmosphere through the gap of the bag holder; the outside of the bag holder is additionally With a dust removal port, a very small amount of dust escaping from the gap between the bag mouth and the bag holder is filtered and collected.

The cut-off door is installed on the discharge opening of the vertical trough. When the weighing is finished, the cut-off door is automatically closed to prevent the material from dripping and affecting the accuracy. Automatic start, automatic peeling, automatic air volume compensation. If the weight of the material in the bag is too poor, the packaging machine will give an alarm.

1. Display PLC Controller:

1.1 Touch screen operation interface, prompt and intuitive, easy to set weighing control parameters can be input through the button, and there are Chinese help menu prompts, with real-time monitoring and other functions; and password protection can be set.

1.2 The operation panel satisfies the package quantity and the number of packaging times automatically display (the current package weight value and the package count value are displayed at any time, and it is convenient to set the fast and slow input value - the material door switching value), automatic/manual switching, out-of-tolerance alarm, fault self-diagnosis (with fault self-diagnosis function, and can display the fault type by code). At the same time, it can automatically control each set of the number of loadings per scale, no need to manually point bags.

1.3 The weighing PLC should have calibration, automatic tracking of zero point, peeling and other functions. The operator issues commands through the buttons on the weighing control cabinet the function can be determined according to the weighing process status and adjusted by the pumping check calibration (platform scale with indexing value ≤ 50g).

1.4 Power-off Protection: with power-off protection function, after a sudden power failure, the system will automatically save the state, and the material door will return to the initial state, which will not cause material overflow and blockage.

1.5 The data transfer between the weighing control cabinet and the RIO can be done via a serial connection (RS485).

1.6 The processing software includes user dialogs (process and configuration parameters, test and inspection methods, etc.), weighing data control, process monitoring, fault detection and signaling systems.

2. Belt feeding method is divided into fast, medium and slow feeding methods.

3. There are class, Nissan, and cumulative production information automatic storage functions.

4.Equipment material: stainless steel and carbon steel.

5.Bag type: woven bag, polypropylene plastic bag, etc

6.Operating Time: 8000 hours / year

Ambient Temperature: 10-40°C

The electronic control system shall meet the above-mentioned equipment operating in the chain requirements.

7.Gas Source: the buyer is responsible for the gas source.Exhaust Pressure:0.4-0.65Mpa.

Technical Parameters:

JK-KLBZ25 Packing Machine Technical Parameters |

| |||||||||||||||||||||||||||||

Model | Bucketless | Single Bucket | Double bucket |

| ||||||||||||||||||||||||||

Packaging range | 5-25kg 20-50kg | 5-25kg 20-50kg | 5-25kg 20-50kg |

| ||||||||||||||||||||||||||

Packing speed | 2-4 bags / min | 4-7 bags / min | 8-12 bags / min |

| ||||||||||||||||||||||||||

Dimensions | Can be customized | Can be customized | Can be customized |

| ||||||||||||||||||||||||||

Power supply | AC380•50HZ 0.9KW | AC380•50HZ 0.9KW | AC380•50HZ 0.9KW |

| ||||||||||||||||||||||||||

Control method | Touch screen | Touch screen | Touch screen |

| ||||||||||||||||||||||||||

The above product information is for reference , according to the material properties (size, shape, fluidity, dust), speed, accuracy, specifications, output, etc., choose the appropriate model, please consult the sales staff first.

The conveyor is used to move the package from one location to another without additional operational control. Set up with forward and reverse job function. The frame is made of carbon steel sprayed material, full roller installation and industrial grade traction conveyor belt of nitrile tape. The roller is made of stainless steel. The motor adopts stepless speed regulating motor with power of 0.75KW.

Technical Parameters:

Conveyor:

|

| |||||||||||||||||||||||||||||

Sewing Unit:

Sewing machine can be set on the column of the sewing machine and the control switch of the reserved belt conveyor and the he adjustable height is suitable for the height range of the design package.

Sewing machine | |

Maximum sewing thickness | 8mm |

Speed | 1700~1800rpm |

Stitch length | 6.5~11mm |

Needle type | 80800x250# |

Wire cutter | Mechanical |

Drive motor power | 380v , 50Hz |

1.Q:How to order?

A:Step1,please tell us what kind of materail do you want to pack,what kind of machine material do you need and the output per hour/day;

Step 2,then we will make a quote and PI for you to confirm the order detail;

Step 3,when we confirmed everything,can arrange the payment;

Step 4,finally we deliver the machine within the stipulated time.

2.Q:When will make delivery?

A:Delivery time:10 to 15 days after pay the deposit.

3.Q:After -sales Service

The warranty period is one year.Ensure that the goods supplied meet the quality specifications and performance of the contract in all respects.Ensure that the equipment has been properly installed and adjusted to meet the contractual requirement after the entire system is in operation.Provide quantitative packaging scales with advanced design and excellent materials. The main components are selected from famous domestic and foreign manufacturers.If the quality or specification of the goods is found to be inconsistent with the contract, or the goods are defective, the buyer has the right to exchange the parts and return goods.

TEL: 400-805-8898

155 3838 8890

Wechat: jy15538388890

E-mail: jiayuequipment.163.com

Whatsapp: +86 15538188278

Похожие товары

Конкурентоспособная цена, хорошее качество для клейкой пены с закрытыми ячейками

6 Вт A15 Светодиодная лампа дневного света 60 Вт эквивалент E12 E14 E26 маленькая лампочка 2700K 5000K потолочный вентилятор лампочки

Буровая установка для бурения скважин, буровая установка, цена XY-44A 1000m Глубина

Эластичная крепированная повязка

Лидер продаж, насадка для швабры из микрофибры для влажного пола

Армейская/военная палатка Sentry Box

Качественные 2021 новые семена хлопка с большим хлопковым болтом и высокой урожайностью

Новые поступления

Новинки товаров от производителей по оптовым ценам