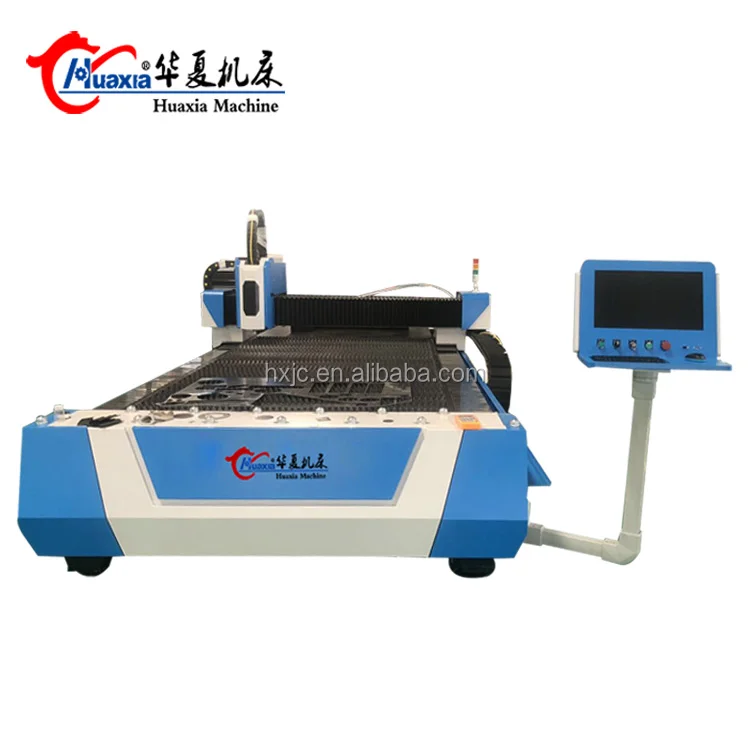

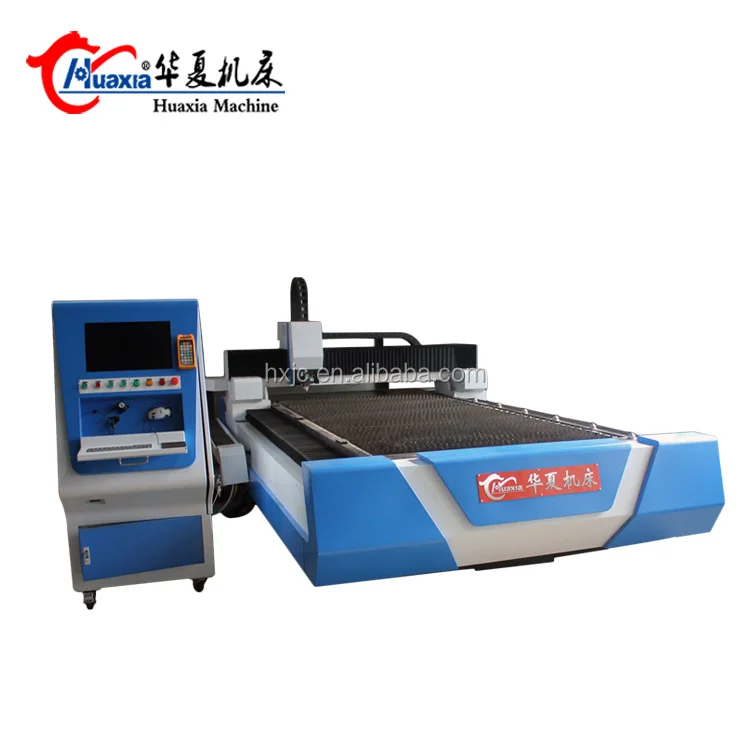

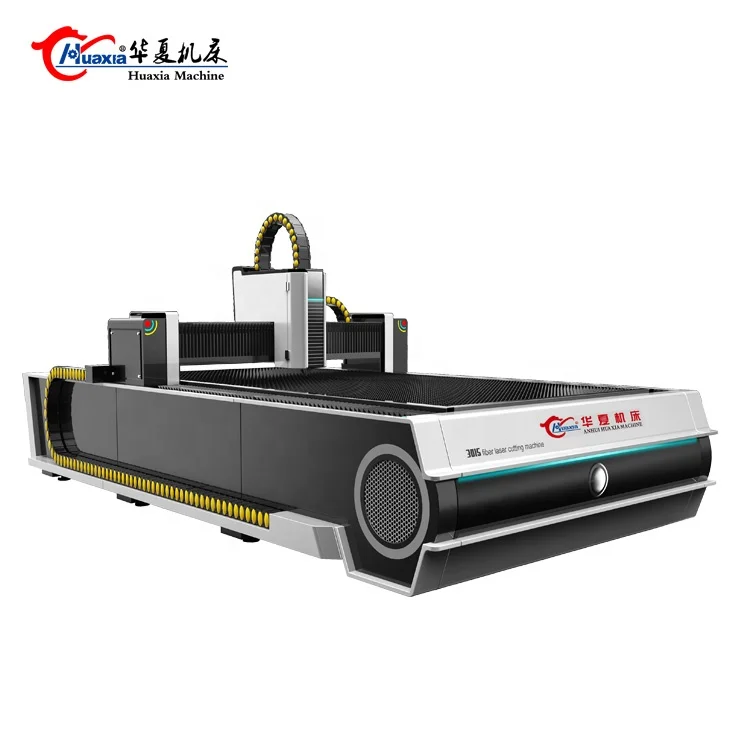

Лидер продаж высокоскоростная машина для лазерной резки металла HUAXIA по разумной цене 2000 Вт

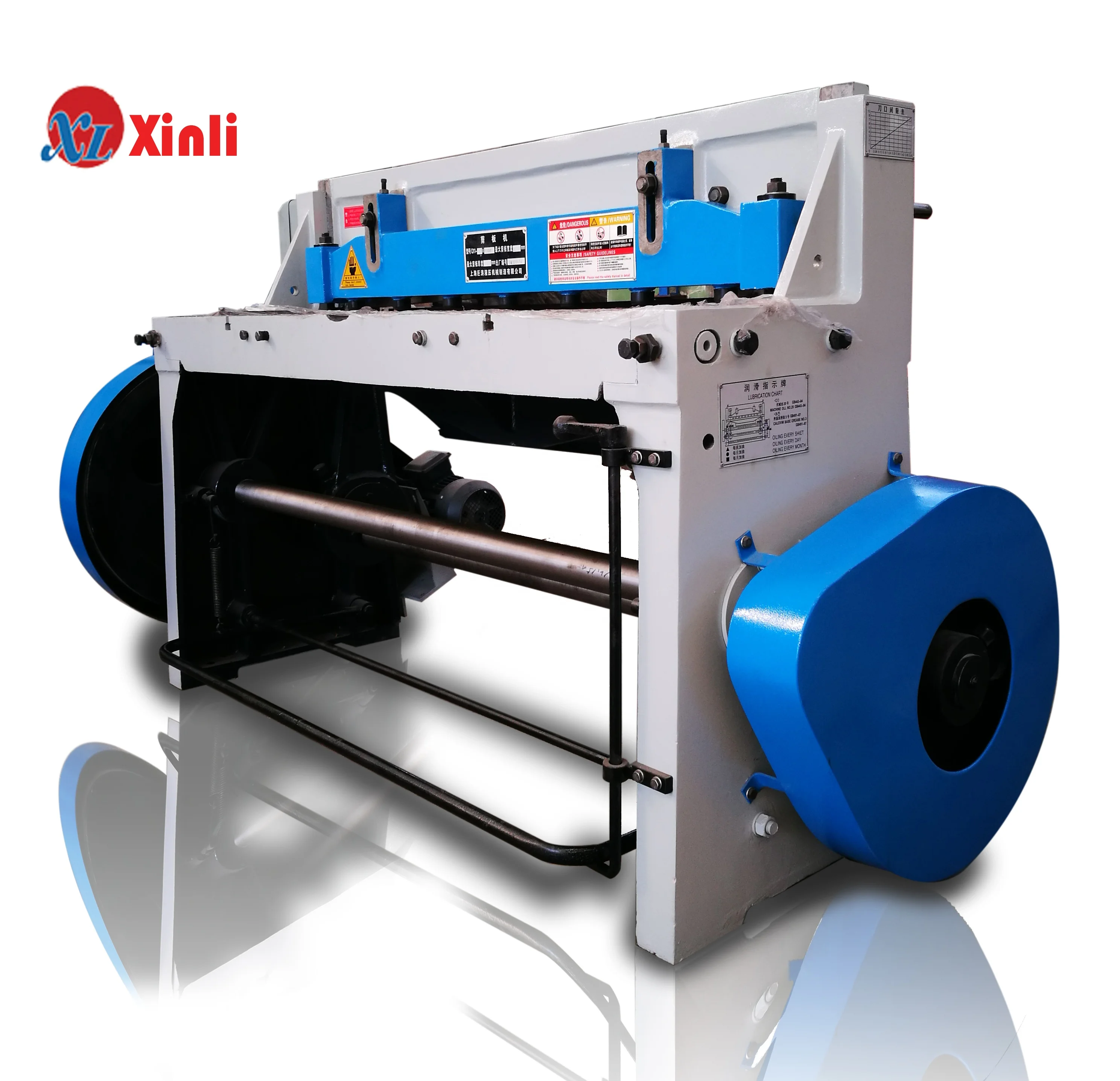

- Категория: Стригальная машинка >>>

- Поставщик: Anhui HuaXia Machine Manufacturing Co. Ltd.Anhui Ltd.

Сохранить в закладки 62265801761:

Описание и отзывы

Характеристики

Main Feature

1.Using high-quality steel plate and welded pipe shaped frame structure,with treatment of welding,aging treatment,precision machining by large grantry milling machine,the machine body have excellent shock resistance,high rigidity and stability,which will ensure the accuracy and running smoothly in the high-speed and long time

2.It adopts cast aluminium intergrated structure,machining treatment,lightweight,rigid,high stability and good dynamic performance

3.The cutting head have functions of surface automatic tracking,manual focus,high-pressure cutting,auxiliary cooling nozzles ETC. Stable and reliable performance,easy to use. It is available for high pressure cutting and low pressure cutting,with a non-contact height automatic tracking system

4.Gas distribution system adopts centralized control,different auxiliary cutting gas can be switched by the control system automatically,and flow pressure can be adjusted automatically. Machine body has an air path control section inside,Air Compressor,Air Dryer,and filter will be required if cutting gas is air

5.Sufficient cooling of critical components to ensure the safe operation of the machine. Chiller has two sets water pipes,one set low-temperature water to cool laser,one set room temperature water to cool QBH joint(collimating lens) to prevent condensation

6.Chillers can be linked with laser and automatic control operation,with the function of safety protection,over-temperature protection,phase,pressure,water lack,undervoltage,overload protection.Stable performance,easy to maintain,all core components are imported parts.

7.Cypcut laser cutting control system is a set of system software designed for plane laser cutting,including laser cutting process,common layout function and laser processing control,most of its functions are applied in graphics processing,parameter settings,custom cutting process editing,layout,path layer palnning,simulation and cutting process control.

8.Taiwan YYC/KH Rack & Pinion,Taiwan CSK/PMI and France Motoreducer

Pre-Sales Service

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine.

Our team

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing Details : plastic film and wooden cases optional

Delivery Details : 3-30 days after order

Q: Guarantee period

A: Our product quality guarantee period is 12 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions is caused by customers' incorrect operation, we will provide spare parts at cost price. We can also offer flexible extended warranties according to the actual situation

Q: After-sales services

A: Our engineer can go to your factory for installation and show operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Q: Why choose us

A: 1.We will the machine for few days, and use your materials to do the test. Only guarantee the machine to show the best performance, and then we will ship it out.

Q: How can we provide you efficient services (metal processing solution)

A:There are Three Steps as following:

2. Analyze your information and provide our feedback

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products we can offer professional designing.

Похожие товары

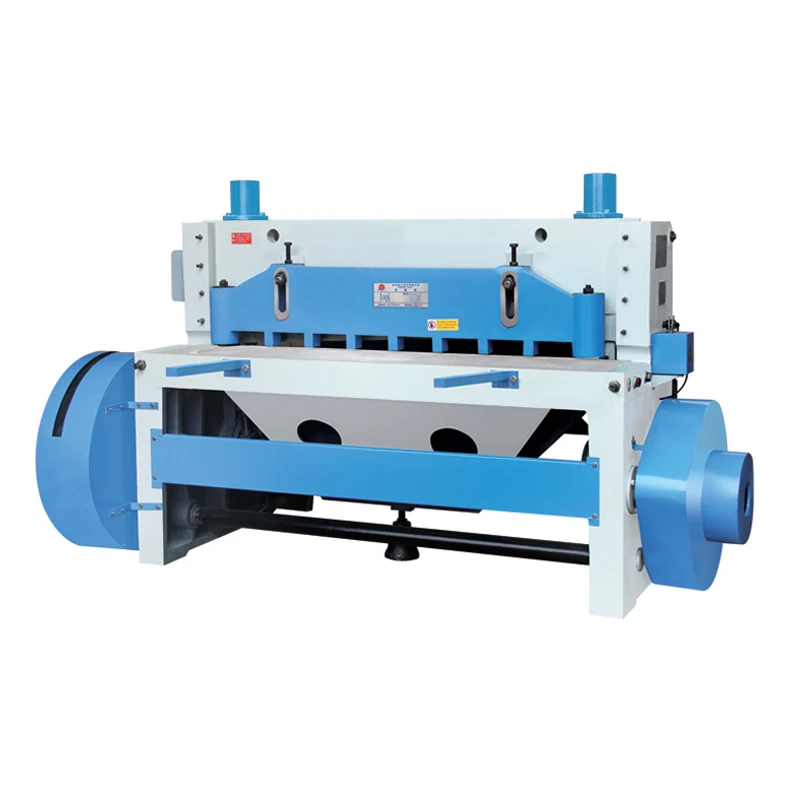

Гидравлические гильотинные ножницы 6*2500 мм с немецкой системой управления ELGO P40 NC в

Хорошая цена Q11 3*1300 мм электрические ножницы для листового металла гильотинные 2*3000 резак железной

Маленькая миниатюрная машинка для резки листового металла, стальная машинка для резки листового металла, цена, машинка для резки листового металла, для продажи, машинка для резки металла mac

Ножной ножной станок Педальный для резки листового

Q11-3 * 1500 гильотина

QB11-6 * 1500 ножницы гильотинные машина для резки листового

Портативный гидравлический ножницы QC12Y 6X2500, гидравлические ножницы из листового железа с CE

Новые поступления

Новинки товаров от производителей по оптовым ценам