Производитель пластмассовых маточных смесей для мусорных контейнеров

- Категория: >>>

- Поставщик: Shandong Huaxiang Plastic Co. Ltd

Сохранить в закладки 62273894434:

Описание и отзывы

Характеристики

Plastic Desiccant Masterbatch Manufacturer for Waste Bin

Desiccant Masterbatch(also known as defoming masterbatch, dehumidification masterbatch, water-absorbing masterbatch) is suitable for damp original material PE, PP and recycled plastic products. It has a very serious impact on the production of plastic products if raw material contains trace moisture or moisture. Generally,enterprises use drying equipment to dry plastics. This is a great waste of energy and manpower and increases the production cost.It only needs to be added to the raw materials and stirred evenly , without any adjustment to the production process.

And the problems of bubbles, moire, cracks, spots, etc. that caused by moisture will be solved.

Using Method:

Stir desiccant masterbatch and the damp plastic raw material uniformly, then produce product.For example, for blown film production, the addition ratio is 1% to 2%. For sheet and injection molding production, the ratio is 2% to 5%. For pipe production, add 2% to 5%. The specific proportion should be added according to the moisture content of the plastic.

Note:

1 The masterbatch should be avoided moisture absorption before use.

2 It is best to use with ingredients immediately 3 It should not be heated and dried with damp plastics to avoid poor quality during processing.

3 Check the packaging is whether intact or not before opening the package and seal packaging of unused masterbatch as soon as possible.

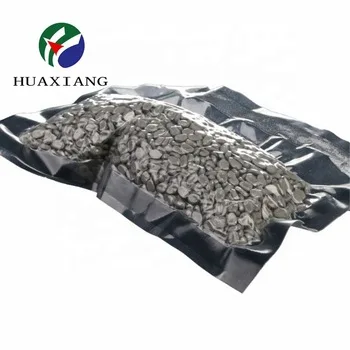

Packing:

Vacuum packing, 1KG, 2.5KG, 5KG, 25KG per box. Damage and open storage are strictly prohibited to avoid sun exposure and rain.

Product Advantage:

Plastic Desiccant Masterbatch Manufacturer for Waste Bin | ||

Index | Value | |

Carrier | PP/PE | |

Color | Black/White/Grey | |

Calcium oxide content | 75%-80% | |

Melt index (21.6KG/200℃) | 5-40g/10min | |

Melting temperature | 140℃-200℃ | |

Water absorption | ≥20% | |

Phase fusibility | PE/PP/PVC/ABS | |

Standard | ISO9001, RoHS | |

Product Application | Palstic processing: Film Blowing, Blow Molding, Injection Molding, Extrusion Molding, Casting Film, Wire Drawing | |

Plastic Desiccant Masterbatch Manufacturer for Waste Bin :

Drainage pipes, moulding products, bag products, sheet products, film blowing, blow moulding products and injection moulding products.

Our Advantages:

1.8 black/white/color masterbatch production lines, 4 desiccant masterbatch production lines and 3 caco3/baso4/na2so4/talc/nano filler masterbatch production lines.

2.The annual output is 100,000 tons.

3.Passed RoHS, ISO 9001:2015, ISO 14001:2015 and OHSAS 18001:2007 certification.

4.15 years of Masterbatch manufacturer.

Production Process

Q1. What is masterbatch?

A: It is solid additive for plastic used for plastics Or imparting other properties to plastic

Q2. How to use masterbatch?

A:Step 1: Confirming the Dosage Ratio.(Usually we suggest proportion is 1%-4%, it is depends on your request.)

Step 2: Mixing the raw material and masterbatch together by blender mixer according to the dosage ratio.

Step 3: Arrange the production as usual.

Q3. What is your MOQ?

A: MOQ is 1KG sample for test.

Q4:Is Sample free?

A: Yes,sample is free, but express fee like DHL,Fedex,etc is collected.

Q5. What is your term of payment?

A: We usually accept Paypal, T/T, L/C ,Paypal etc.

Q6. How to proceed an order for masterbatch?

A: Firstly, let us know your requirements or application.

Secondly, We quote according to your requirements or our suggestions.

Thirdly, customer confirms the samples and places deposit for formal order.

Fourthly, We arrange the production.

Q7,How to guarantee the quality?

A:Our products are passed , we have quality controller who do test everyday.

Q8,How about Lead Time?

A:Our daily production for each product is 30tons. So generally, lead time is in one week. It's depend on your order quantity.

Похожие товары

Оптовая продажа с завода, осушитель, пластиковые гранулы, низкая цена, мастеры/пластик

Противопожарное спасательное оборудование для штатива

Британская армия, Золотая проволока Aiguillette, американский военный офицер, военно-морской флот, времен Второй мировой войны

Беспроводная роботизированная косилка WORX WR155, 20 в, LANDROID L, 1/2 акр, аккумулятор 6,0 Ач

Navifly PX30 Android 9,0 четырехъядерный автомобильный радиоприемник для VW Skoda Octavia golf 5 6 touran passat B6 Tigua polo jugador jeeta IPS + DSP

Робот-косилка E1800st с Умной высотой резки

Автомобильный dvd-плеер MEKEDE ID7 UI Android 7,1 для BMW 3 серии E90 5 серии E60 CIC система с 2 + 32 ГБ 16 ГБ бесплатной картой ADAS

Новые поступления

Новинки товаров от производителей по оптовым ценам