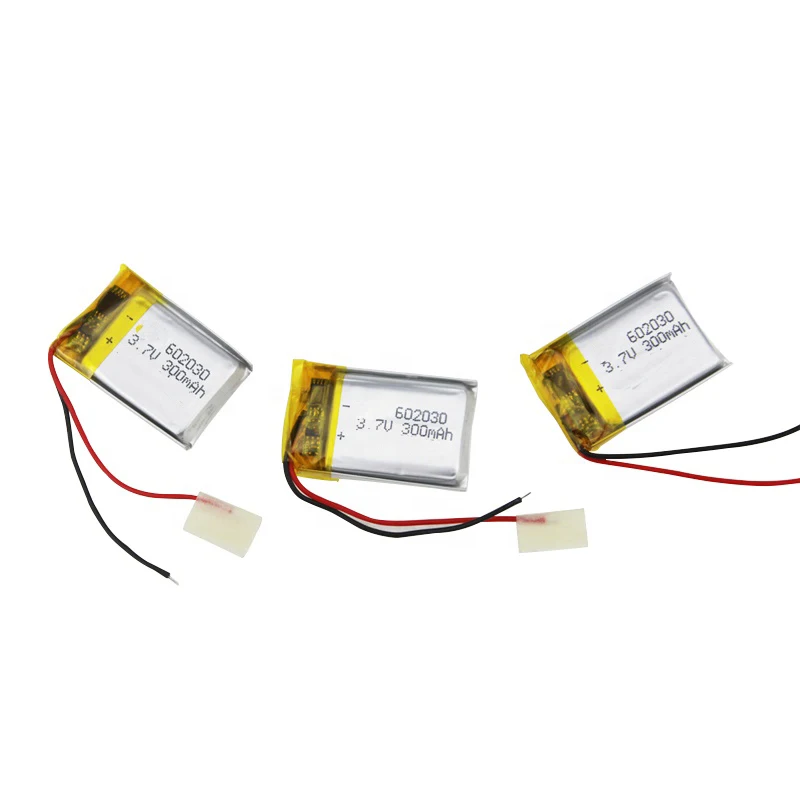

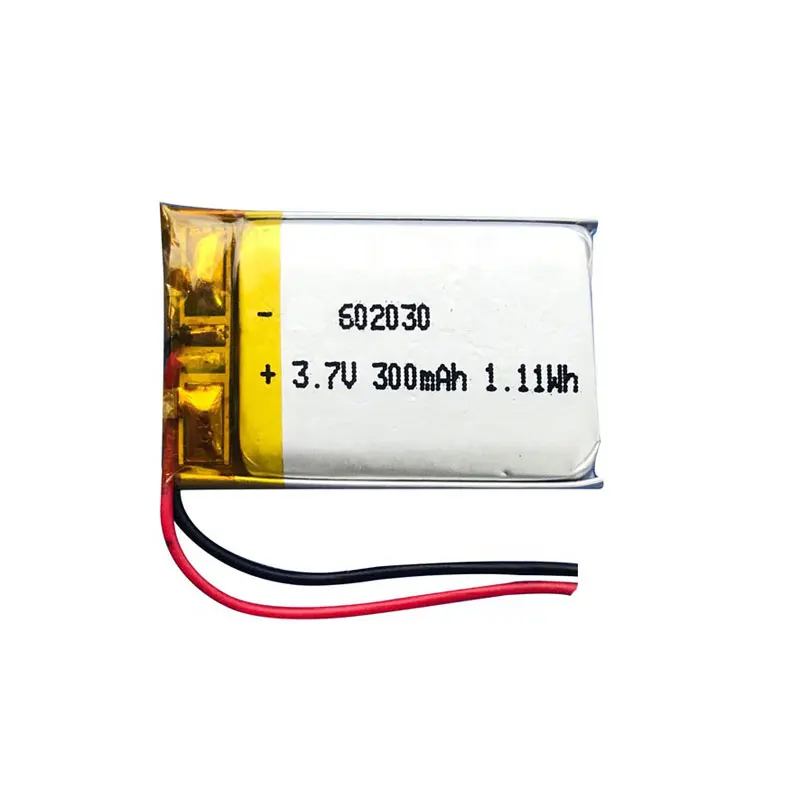

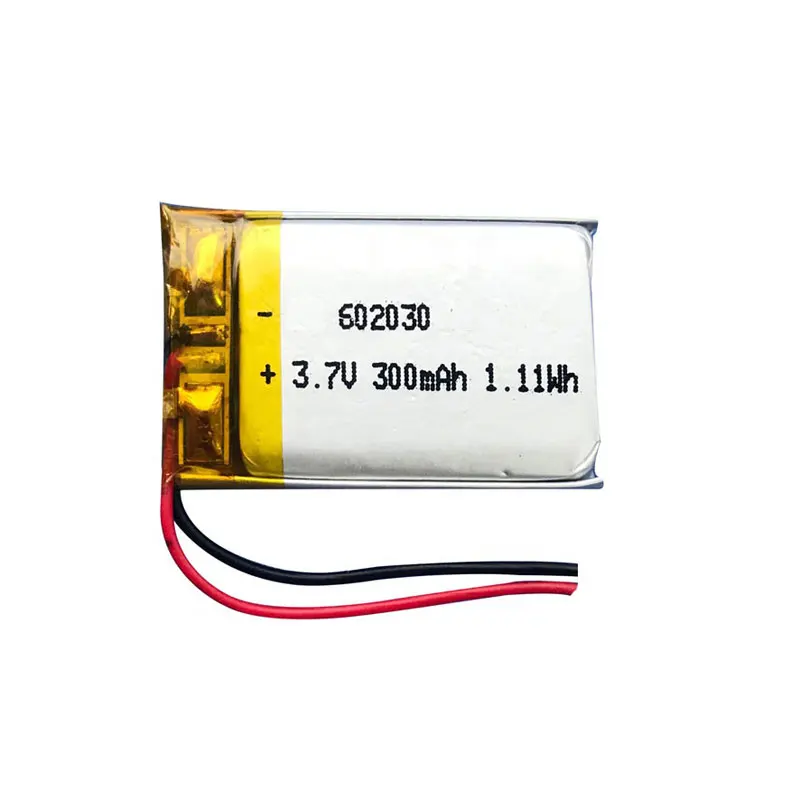

Одобренная WERCSmart 3 7 V 300mah литий полимерная батарея 602030 перезаряжаемая

- Категория: >>>

- Поставщик: Shenzhen Herculesi Technology Co. LtdShenzhen Ltd

Сохранить в закладки 62276107586:

Описание и отзывы

Характеристики

Walmart Supermaket Approved 1.11Wh E0630 Li Ion Polymer Battery 3.7v 300mah Rechargeable Battery with UL/UN38.3/WERCSmart/KC

Herculesi carries a li-polymer battery for virtually any application.

With varying amperages, shapes, weight ,and sizes, you are sure to find a lithium-polymer battery for whatever device you need.

| Product name | 3.7V 300mAh Lithium Ion Battery |

| Model | 602030 |

| Capacity | 300ah |

| Voltage | 3.7V |

| Sizes | 6.2*20*32mm |

| Certification | U L ,UN38.3,WERCSmart,KC |

| Max discharge current | 1C |

| Max charge current | 0.5C |

| Charging temperature | 0-45C |

| Discharge temperature | -20-60C |

| Cycle lifes | more than 500 times |

| Charge full voltage | 4.2V |

| Discharge cut-off voltage | 2.75V |

| Warranty | 12 months |

| Application | Sports bluetooth headset ,Smart - Watch |

| Free samples | To be negotiated |

| Features | Battery can be in Walmart Supermaket |

| Model | Capacity | Size | Certification |

| 401012 | 3.7V 35mAh | 4*10*12mm | KC |

401122 501015 501318 | 3.7V 55mAh | 4*11*22mm | KC U L |

| 431220 | 3.7V 75mAh | 4.3*12*20mm | U L |

| 802040 | 3.7V 600mAh | 8.2*20*42mm | UL1642 |

802050 803035 | 3.7V 800mah 3.7V 800mah | 8.2*20*52mm 8.0*30*35mm | UL1642 / KC KC |

| 802528 | 3.7V 480mah | 8.2*25*30mm | KC/ U L / UN38.3 |

| 802540 | 3.7V 650mah | 8.0*25*40mm | U L |

| 802456 | 3.7V 850mah | 8.0*24*56mm | U L |

| 802470 | 3.7V 1500mah | 8.0*24*70mm | KC |

| 825095 | 3.7V 3500mah | 8.2*50*95mm | U L |

| 803048 | 3.7V 1200mah | 8.2*30*50mm | UL1642 |

| 803450 | 3.7V 1500mah | 8.2*34*52mm | KC/UL/CB/IEC62133 |

804050 952989 103562 | 3.7V 2000mah 3.7V 2000mah 3.7V 2000mah | 8.2*40*52mm 9.5*29*89mm 10*35*62mm | UL1642 U L U L |

| 804068 | 3.7V 2500mah | 8.2*40*70mm | KC |

| 832248 | 3.7V 920mah | 8.5*22*50mm | KC/UL1642/UN38.3 |

| 851735 | 3.7V 500mah | 8.5*17*35mm | KC |

| 854467 | 3.7V 2500mah | 8.5*44*67mm | U L |

| 901744 | 3.7V 680mah | 9.2*17*46mm | KC |

| 902030 | 3.7V 500mah | 9.2*20*32mm | KC/UL1642/UN38.3 |

902035 102030 | 3.7V 600mah 3.7V 600mah | 9.2*20*37mm 10*20*30mm | KC/UN38.3 KC/UN38.3 |

| 902535 | 3.7V 800mah | 9.2*25*37mm | KC |

| 903450 | 3.7V 1600mah | 9.2*34*52mm | KC |

| 951768 | 3.7V 1200mah | 9.7*17*69mm | KC |

| 985362 | 3.7V 4000mah | 9.8*53*62mm | U L |

| 102040 | 3.7V 750mah | 10*20*40mm | KC |

| 102530 | 3.7V 700mah | 10*25*30MM | KC |

| 102540 | 3.7V 1200mah | 10*25*40mm | KC |

| 103048 | 3.7V 1050mah | 10*30*48mm | U L |

| 102055 | 3.7V 1100mah | 10.2*20*57mm | KC/UL |

| 102050 | 3.7V 1000mah | 10.2*20*52mm | KC/CB/IEC62133/UL/UN38.3 |

| 102550 | 3.7V 1200mah | 10*25*50mm | KC |

| 103040 | 3.7V 1200mah | 10.2*30*42mm | KC/UL1642 |

| 103450 | 3.7V 1800mah | 10.2*34*52mm | KC/UL/UN38.3 |

| 104050 | 3.7V 2300mah | 10*40*50mm | KC |

| 105050 | 3.7V 3000mah | 10.2*50*52mm | KC/UL1642 |

| 105085 | 3.7V 5000mah | 10.2*50*87mm | UL/CB/UN38.3/IEC62133 |

| Others | |||

Application 3.7V 300mAh 602030 Lithium polymer battery:

Telecommunication: cellular phone, web phone, interphone, Bluetooth earphone. Portable office devices: Notebook, PDA, portable electrograph, portable printer. Video devices: GPS, digital camera, camcorder, portable DVD, portable television, MP3, MP4. Portable exchange devices: POS, Handy, Fingerprint machine, portable stock machine. Illuminate devices: miner lamp, searchlight. Others: toys, models.Baby bed monitoring

Production Technology of Lipo Polymer cell

Mixing

Mix solvent and bound separately with positive and negative active materials. Make into positive and negative pasty materials after stirring at high speed till uniformity.

Coating

Now, we are in coating line. We use back reverse coating. This is the slurry-mixing tank. The anode(Cathode) slurry is introduced to the coating header by pneumaticity from the mixing tank. The slurry is coated uniformly on the copper foil, then the solvent is evaporated in this oven. There are four temperature zones, they are independently controlled. Zone one sets at 55 degree C, zone two sets at 65 degree C, zone three sets at 80 degree C, zone four sets at 60 degree C. The speed of coating is 4 meters per minute.

You see the slurry is dried. The electrode is wound to be a big roll and put into the oven. The time is more than 2 hours and temperature is set at 60 degree C.

Throughout the coating, we use micrometer to measure the electrode thickness per about 15 minutes. We do this in order to keep the best consistency of the electrode.

Cutting

Cut a roll of positive and negative sheet into smaller sheets according to battery specification and punching request.

Pressing

Press the above positive and negative sheets till they become flat.

Punching

Punching sheets into electrodes according to battery specification,

Electrode

After coating we compress the electrode with this cylindering machine at about 7meters per minute. Before compress we clean the electrode with vacuum and brush to eliminate any particles. Then the compressed electrode is wound to a big roll. We use micrometer to measure the compressed electrode thickness every 10 minutes. After compressing we cut the web into large pieces. We tape the cathode edge to prevent any possible internal short. The large electrode with edge taped is slit into smaller pieces. This is ultrasonic process that aluminum tabs are welded onto cathodes using ultrasonic weld machine. We tape the weld section to prevent any possible internal short. And finally, we clean the finished electrodes with vacuum and brush.

Anode making

In anode making process, we cut the material into certain length strips. At the mean time, we put a small piece of insulation tape to the tab in order to prevent any possible internal short. Then the prepared nickel tab is riveted on anode and pat plain. We also tape the rivet section to prevent any possible internal short. And finally, we clean the finished electrodes with vacuum and brush.

Jelly roll

This is Jelly roll, a manual winding process. In the course of Jelly roll, firstly, we place the separator in between central pins, press the foot switch to turn central pins about 120 degrees. Secondly, place the anode to the edge of central pins, and turn central pins about 180 degrees. Lastly, place the cathode to the edge of central pins. During the winding process, we apply tension by pressing the electrodes and the separator. We put the termination tape at the end.

After Jelly roll, we check the short circuit, then form the Jelly roll by pressing, so that it is easier to insert the Jelly roll into the can.

Control points:

1. When winding to the end of the anode, covering the anode completely by the separator.

2. In the whole process, it is the most important points to ensure the best alignment among the cathode, the anode and the separator for the Jelly roll. The separator has to cover the anode and the cathode, and the anode has to cover the cathode completely. These points are mainly checked before short checking.

Taping & inserting

Put the tape on the two side of J/R, To prevent J/R being hurt in the insertion process.

Put a piece of tape between cathode tab and J/R .Because anode electrode is wider than cathode electrode.

Put the bottom tape.

Insert the finished J/R into the can manually and then short circuit check by multi-meter.

Spot welding Ni tab to cap.

Ultrasonic welding the Al tab to cap using ultrasonic weld.

We have the second spot welding to ensure the best contact between the tab and cap.

Apply top insulator, to prevent Ni tab contacting with can.

Final J/R insertion by the centrifuge.

Cap positioning by hand. Then check the cap in the suitable position, or the defects is put into red bin ,Finally , short circuit check again to ensure that there be no internal short J/R flowing to next line.

Laser welding

This is the Laser welding room! The first process is welding for the aluminum cap, specially connect the rivet with the weld plate to prevent the cell impedance excursion.

The second process is the Laser seam welding. In the process, it must ensure the intensity and airproof characters of the weld.

After the cell is welded, we would perform the leak checking, the short circuit checking and the weighing checking.

Oven drying electrolyte filling and storing

This is the process of cells oven drying at 80℃ for more than 12 hours under vacuum. After oven drying, the cells are transferred to the process of electrolyte filling through this channel. The electrolyte filling performs in dry room. The electrolyte is injected in two times so that it can be filled easily and sufficiently. When filling, vacuum first, then inject electrolyte. After that, we repeat vacuum and vent to room pressure several times. Finally the cell is put off at room pressure, then weigh the cell in order to check the amount of electrolyte. After weighing, we seal with tape onto the filling port to prevent the cells absorbing water during storing.

We store the filled cells for 24 hours at room temperature so that the electrolyte can be saturated sufficiently by the anodes and cathodes.

Pre-charge and ball seal

At first, we place a piece of absorb cotton above the filling port to absorb the excess electrolyte. This is the first process.

The second process is performing a pre-charge at 0.1C rate for 390 minutes.

After the pre-charge, we take a voltage checking to the cell at once. If the voltage is lower than the standard, it needs to be re-charged.

The fourth process is the ball seal. we must complete this process in 15 minutes.

First, put the steel ball in the right place. Then, give pressure to it so that the steel ball can fill the filling port.

In the whole process, we must make sure that the temperature and humidity are in the regular range.

Finally, the process is cleaning to eliminate the electrolyte on the cell surface with acetone solvent.

Aging and Formation

This is the aging room. We age cells at 35~40 Degree C for 7 days. The temperature is controlled by two heating instruments which are set at 38 Degree C. Then we transfer cells to the testing workshop. First, we check the voltage of cells with multi-meters. According to voltage, we divide the cells into acceptables and defects. Formation is done at 1.0 Capacity rate for 140 minutes to 4.2 Voltage. After that, check thickness and impedance. At last, we transfer the acceptables to the storehouse.

Li-Polymer battery are made of soft aluminum-plastics compound packaging .Internal is half solid polymers.Discharge stability, high efficiency, the internal resistance small.safety performance is better, and has overcurrent, overvoltage protection devices. Cycle life is more than 500 times.

Evolving from Lithium-ion batteries, Lithium polymer batteries offer a distinct advantage over their predecessor in terms of cost, utility, durability and flexibility. A Lithium-polymer battery can be shaped to fit in an array of devices. As cell phones become thinner, it is important for battery manufactures to develop new ways to charge these ever important devices.

Using a lithium-polymer battery allows the manufacturer to shape the battery in essentially any way they please. This allows for more freedom in designing the true power behind our mobile devices. Another advantage of lithium polymer cells over nickel-cadmium and nickel metal hydride cells is that the rate of self-discharge is much lower.

Category : Ultra Thin Rechargeable Cells

Lithium Polymer batteries (LiPo) offer several advantages. It has a greater energy density in terms of weight than Lithium Ion. In very thin cells (under 5 mm) LiPo also provides higher volumetric energy density. Additionally, there is more flexibility in cell sizes and shape with LiPo and a wider margin of safety, with superior stability in over-voltage and high-temperature conditions.

Major Features:

Super thinness: 0.5-1.0mm

High energy density / High capacity High safety

High rate discharge performance

Special shape : Arc-shape, Trapezoid-shape, Rectangle-shape, I-shape, Narrow-shape

Best use of potential rooms of products and perfect for small portable electronics.

Q1: Are you a manufacturer or a trading company?

A1:company is a professional manufacturer which can provide you competitive price and stable product quality.

Q2: Do you have any MOQ limit for the order?

A2: We have low MOQ

Q3: Can you customize the battery?

A3: Yes, We have our own battery cell factory. We can produce the battery core according to customers' requirements and compose the battery according to customers' request. So, if you can't find suitable battery dimension in our website, please directly contact us to confirm whether we can offer what you need!

Q4: Do you test all your goods before delivery?

A4: Yes, we have 100% test before delivery.

Q5: What kind of certificates could you provide for the battery?

A5: We have certifications for many battery models, but usually this is custom-making design and we don't have current certificate. But we can apply CE, UL, UN38.3, KC, BIS, MSDS and other related certificates for you if you need it. And the certificate fee needs to be paid by you. If your order is large order, certificates fee could be refunded!

Q6 : Do you provide free samples ?

A6: For big order ,Yes ,but you pay shipping cost . For small order ,no .

Похожие товары

Аккумулятор супер конденсатора 200 А 24 В ач

Оригинальный новый модуль батареи Svolt 6S1P 22 2 в Ач для EV

5KWh-150KWh подходит для гибридной/автономной системы мульти-модель высокого напряжения и низкого литиевая батарея

12 В 100Ah 150Ah 200Ah литиевая батарея LiFePO4 Встроенная 100A BMS литиевые батареи глубокого цикла солнечная энергетическая система

Copow roypow более 10 лет промышленная заводская водонепроницаемая литиевая батарея 12 В 200ah lifepo4 24 для лодки

Аккумуляторный блок 280 51 2/48 В

LI23S001A 11 1 V 4400mah Li-Ion аккумулятор замена медицинская батарея для Mindray PM8000 PM7000 IPM-9800 VS800 VS-800

Новые поступления

Новинки товаров от производителей по оптовым ценам