HLSG 400 полностью автоматическая высоко эффективная по индивидуальному заказу влажный порошок гранулятор машина для химических продуктов

- Категория: >>>

- Поставщик: Wenzhou Liangke Machinery Co. Ltd.

Сохранить в закладки 62287704093:

Описание и отзывы

Характеристики

HLSG-400 Fully Automatic High Efficient Customized Wet Powder Granulator Machine for Chemicals

Technical Parameters

Product Name | Fully Automatic High Efficient Customized Wet Powder Granulator Machine for Chemicals |

Model | HLSG-400 |

Total Volume | 400L |

Working Volume | 100-280L |

Material input quantity (material density is 0.5 g/ml) | 50-140KG/batch |

Operating time | Mixing about 2 minutes, granulating 7-14 minutes/batch |

Finished granule size | About Φ0.14-Φ1.5mm (12-100 meshes) |

Mixing motor | 22KW |

Speed of stirring paddle | 25-220 r/min |

Granulating motor | 7.5KW |

Speed of granulating blade | 50-3000 r/min |

Outline dimension (L×W×H) | 2420*1060*2150mm |

Weight | 1900KG |

Product Description

HLSG-series super mixing granulator is a new generation of granulating equipment developed by our company, which can finish the procedures of mixing, wetting, granulating in one time. Which is very effective and in compliance with GMP standard.

This machine is controlled by Siemens PLC, equiped with touch screen, HMI, double frequency control system. At the same time, several of our creative designs are applied on, such as automatic safety protection device, jacket heating and temperature control system etc.. Therefore, it gets high automatic degree, adhesive usage saving, short granulating time, high-quality of finished granules.

This machine can mix different kinds of powder or paste materials. Small solid granules with uniform size and high pelletized ratio can be obtained. It is suitable for mixing and granulating in various industries, such as pharmacy, foodstuff, cosmetics, feedstuff, ceramic and chemicals. And got good feedback from the customers all over the world.

Working Principle

>> The whole process consists of two procedures: mixing and granulating.

>> The adhesive is charged into the material pot from the conical hopper. Along with the filling of adhesive, the powder raw materials keep rotating in the pot under the action of stirring paddles once the hopper is closed. In the meanwhile, they grow up the shape of liquid bridge under continuous effects of conical wall. Under the action of extrusion, friction as well as kneading by paddles and conical pot wall, all materials gradually turn loose and soft. At last, open the material outlet and the wet granules will be pushed out under the centrifugal force of paddles.

>> The soft materials are granulated via the granulating cutters but not the forced extrusion, which will be cut into tiny and uniform granules under the semi-fluid state, realizing the mutual transformation between two different materials.

Detailed Images

Breather+Viewing Port+Liquid Hopper Lifable Stirring Paddle Granulating Chopper

Discharge Port Siemens Touch Screen Wet Pelletizer - can be connected with the wet granulator for uniforming granules got

(optional device)

Our Advantages

>> The paddle can be lifted about 3cm automatically, easy for pot cleaning, manpower saving, no dead angles and no residue.

>> With 3 seals: Imported skeleton seal (upper and lower), gas seal, the exclusive developed third separation seal of our company. Make sure no transmission system, bearing lock and materials polluted.

>> Siemens PLC, touch screen and dual frequency control system.

>> 45° bevel of the material outlet port, material outlet automatically.

>> No dead angles, no residual, easy to be cleaned.

>> Belt transmission, no oil leaking, easy to be changed if worn. Cheaper and economic.

>> Pot bottom with jacket for cooling, avoid motor lock caused by overheated material which stick to the pot wall.

>> Operating platform has no dead angles, easy to be cleaned and meets the standards of GMP (CGMP).

>> Automatic pot-cover opening and closing system, pneumatic components and security alarming device are applied.

>> The gap between the paddle and pot bottom can be decreased to 0.5-1mm. Thick stainless steel used from 8-12mm, high grade, not easy to be deformed.

Certifications

Customer Photos

Factory Workshop

Wenzhou Liangke Machinery Co., Ltd.

Wenzhou Liangke Machinery Co.Ltd. is an enterprise specialized in the developing, manufacturing, marketing ans servicing of solid

dosage production line. With a history more than ten years, our machines are widely applied in many fields, such as pharmacy,

foodstuff, health care product and chemical industry. Over the years, our factory has been rated as credible unit, level A

credible unit, SME of development and technology in Zhejiang Province, SME of technology in Zhejiang Province, and enterprise of

technology (innovation) in Wenzhou City. Besides, with various professional domestic certificates, such as invention patent, our

machines have also passed the CE certificate. Our machines win a wide market both at home and abroad, including the overseas

countries and regions such as America, Europe, Oceania, South America, West Asia, Middle East and South-east Asia etc..

Our main products include the following: high efficiency wet granulator, pellet granulating and coating machine, roller compactor,

fluid bed dryer, three dimensional mixer, cone mixer, bin blender, quick type cone and milling machine, and the related cleaning

machine.

The main feature of our machines and services are as following:

1. With a long life based on the top-ranking raw material and electrical and mechanical parts we adopted on the machine.

2. With our patented design and technology, our machine is simple to operate , easy to clean without dead corner, and mostly

importantly, safe for operator.

3. All our machines are in strict accordance with CGMP.

4.We will design the machines for customer with special requirement and room layout, and we provide stable after sales service

including installation, training and remote assistance.

Welcome to our factory or contact us for more information.......

dosage production line. With a history more than ten years, our machines are widely applied in many fields, such as pharmacy,

foodstuff, health care product and chemical industry. Over the years, our factory has been rated as credible unit, level A

credible unit, SME of development and technology in Zhejiang Province, SME of technology in Zhejiang Province, and enterprise of

technology (innovation) in Wenzhou City. Besides, with various professional domestic certificates, such as invention patent, our

machines have also passed the CE certificate. Our machines win a wide market both at home and abroad, including the overseas

countries and regions such as America, Europe, Oceania, South America, West Asia, Middle East and South-east Asia etc..

Our main products include the following: high efficiency wet granulator, pellet granulating and coating machine, roller compactor,

fluid bed dryer, three dimensional mixer, cone mixer, bin blender, quick type cone and milling machine, and the related cleaning

machine.

The main feature of our machines and services are as following:

1. With a long life based on the top-ranking raw material and electrical and mechanical parts we adopted on the machine.

2. With our patented design and technology, our machine is simple to operate , easy to clean without dead corner, and mostly

importantly, safe for operator.

3. All our machines are in strict accordance with CGMP.

4.We will design the machines for customer with special requirement and room layout, and we provide stable after sales service

including installation, training and remote assistance.

Welcome to our factory or contact us for more information.......

Похожие товары

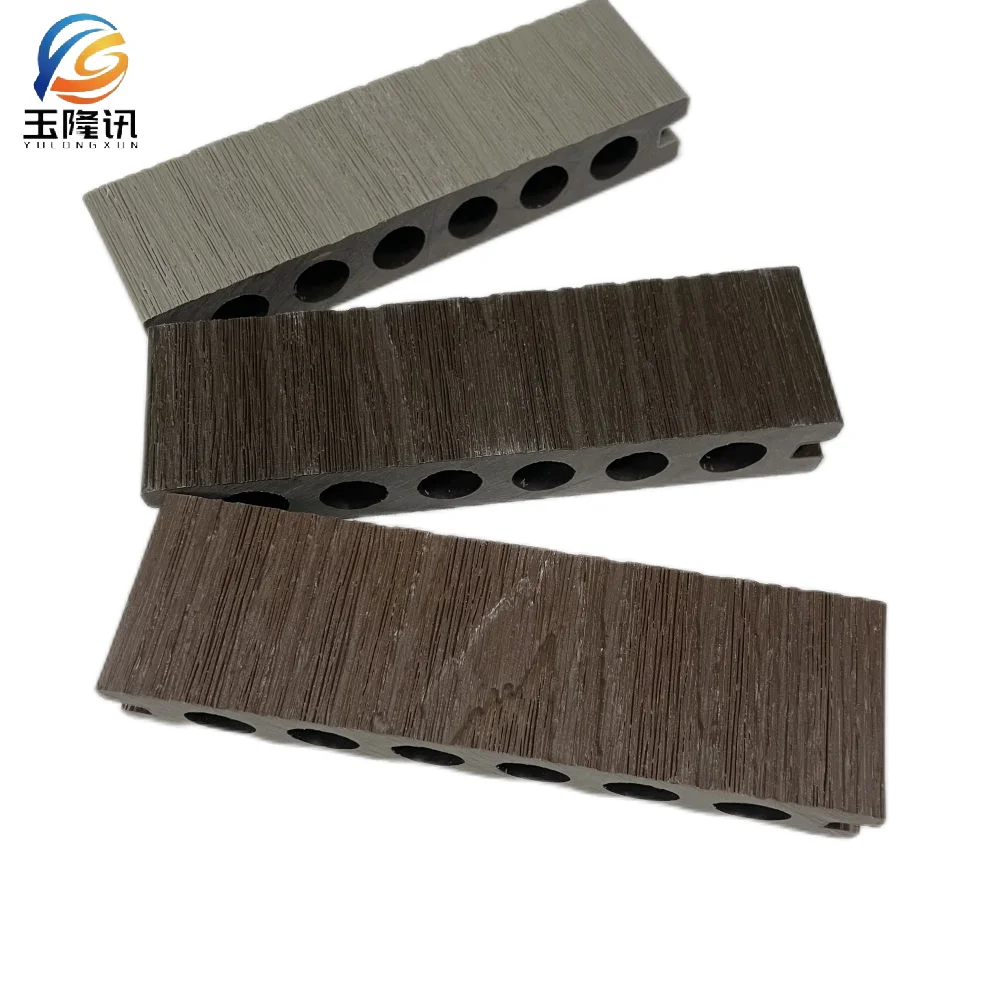

Индивидуальные кровельного материала WPC террасная доска recinzione

2,49 $ - 3,15 $

Kingjoy новая конструкция алюминиевый высокое качество электронный 3-х колесный Долли для фотографии камеры смартфона

55,00 $ - 80,00 $

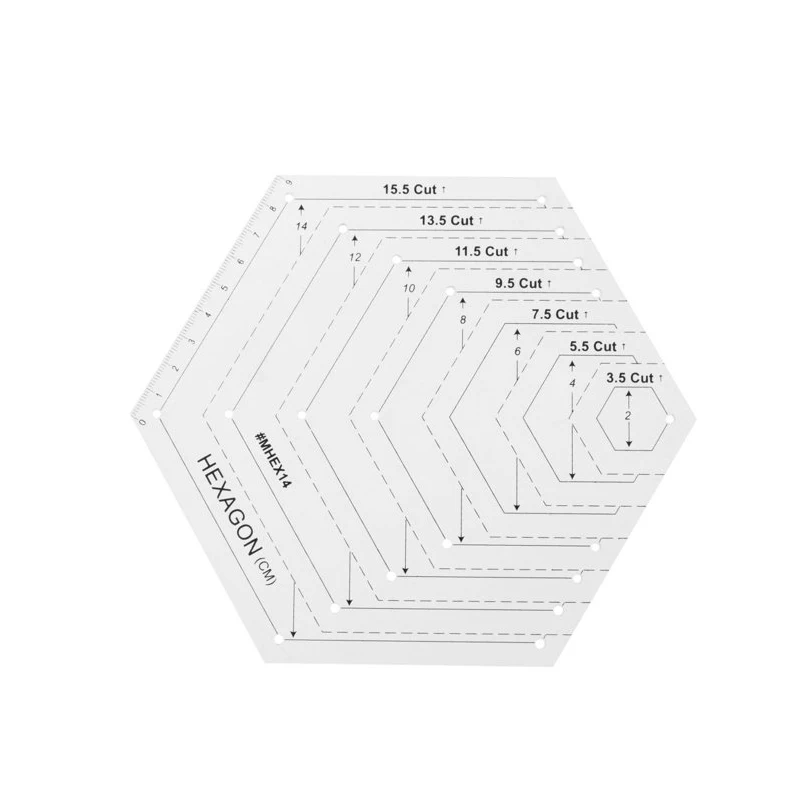

Прозрачная пластиковая линейка для одеял 15x15 см, линейка для лоскутного шитья из акриловой ткани, линейки для шитья

Лидер продаж, эмалированный шведский чугунный набор для фондю с сыром

Стандартные блокировки QTJ4-18 цемента шлака камень земли используется дешевое машина изготовляющая кирпичи производитель оборудования в Танзания

12 000,00 $

OK004 автоматическая этикеточная машина для маркировки на прямой поверхности круглой бутылки

11 000,00 $ - 12 000,00 $

Современный стильный современный журнальный столик из нержавеющей стали и стекла с умным дизайном, мебель для гостиной

72,00 $ - 73,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $