Пластиковая стиральная машина KOOEN для бутылок из полиэтилена повышенной плотности

- Категория: >>>

- Поставщик: Zhangjiagang Kooen Machinery Co. Ltd.

Сохранить в закладки 62289010128:

Описание и отзывы

Характеристики

Plastic bottle recycle crushing washing drying machine hdpe milk bottles scrap plastic washing recycling machine line

Plastic Recycling Machine PET Bottle recycling washing line

Estimated Plant Parameters:

Model | CAPACITY (kg/h) | POWER CONSUMPTION (kw) | WATER CONSUMPTION (ton/h) | Manpower | HUMIDITY CONTENT |

MT-300 | 300kg/hour | 150kw | 3ton/h | 4 | <1% |

MT-500 | 500kg/hour | 230kw | 4-5ton/h | 4 | <1% |

MT-1000 | 1000kg/hour | 270kw | 6-7ton/h | 5-6 | <1% |

MT-2000 | 2000kg/hour | 370kw | 8ton/h | 5-6 | <1% |

MT-3000 | 3000kg/hour | 420kw | 10ton/h | 7 | <1% |

Working Flow:

Belt conveyor → Bale opener machine → Belt conveyor → Pre-washer (trommel) →Belt conveyor → Mechanical label remover → Manual separating table → Metal detector →Belt conveyor → Crusher *2→ Screw conveyor*2 → Floating washer →Screw conveyor → Hot washer chamber *2 →Screw conveyor*2 → High speed friction machine → Screw conveyor → Floating washer → Screw conveyor →Floating washer → Screw conveyor → Horizontal dewatering machine → Drying pipe system → Zig zag air classification system → Storage hopper → Control cabinet

Main Components:

Belt conveyor

Control method: frequency control |

Bale opener machine

Stirring motor: 7.5kw*2 |

Trommel (pre washer)

Dimension(L*W):5000*1500mm; Material of barrel: Perforated plate, galvanized treatment |

Mechanical Label remover machine

Motor Power:11/22/37KW; Blade material: Tungsten steel, removable. Removing labels from bottles, label remove rate reach 99% |

Manual separating table

Dimension (L*W*H): 8000*1000*1200mm |

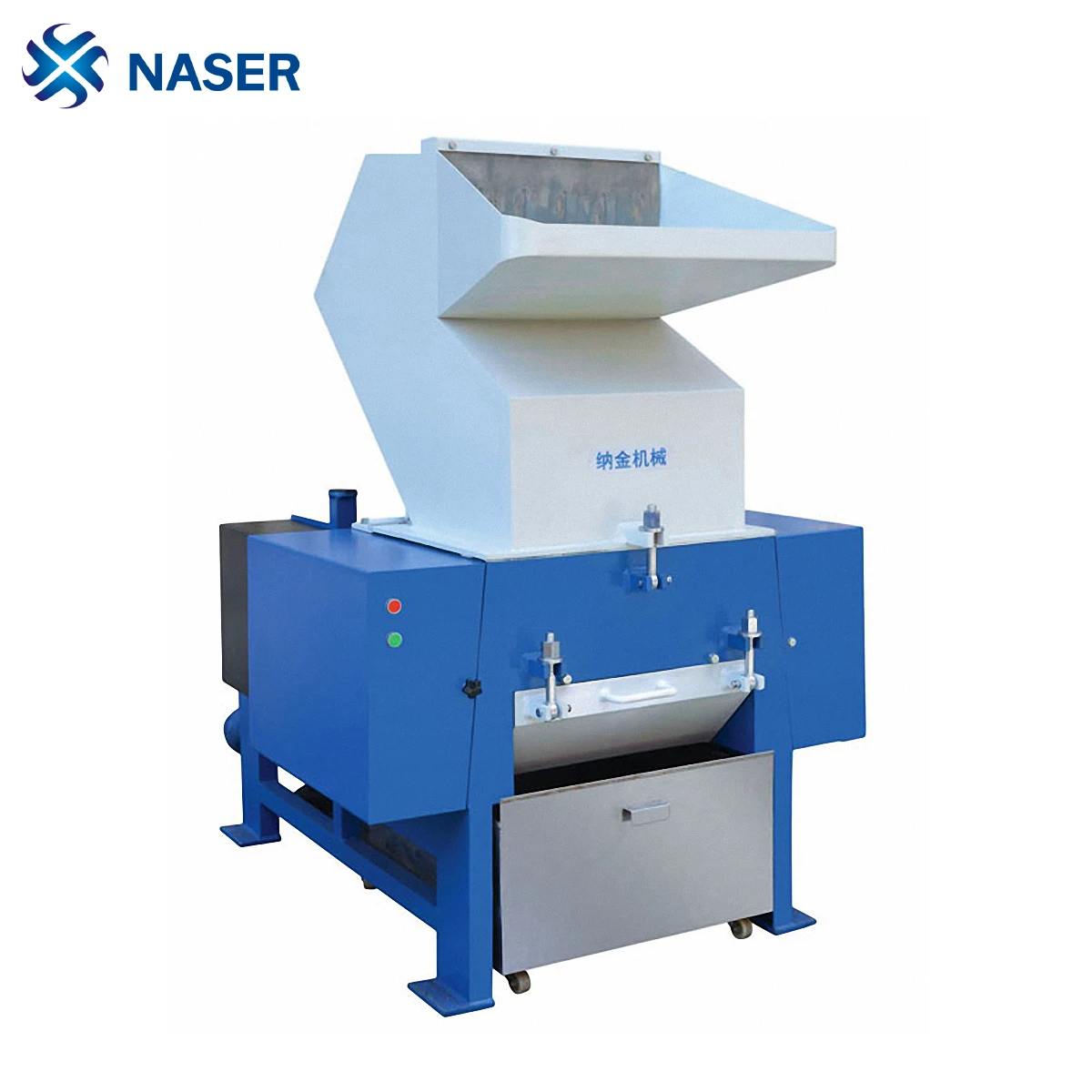

Crusher

Motor power: 37/55/90kw, Knife material: SKD-11(from Japan), crushing with water |

Floating washer

Dimension(L*W): 4500*1500mm, made of SUS304 stainless steel |

Hot washing chamber

Diameter of the barrel: 1800/2200mm, Heating type: Electric heating /Steam heating for option |

High speed friction machine

Motor power: 22/37/45Kw, rotation speed 1200rpm |

Floating washer tank (the second one )

Dimension(L*W): 4500*1500mm, made of SUS304 stainless steel |

Floating washer tank (the third one )

Dimension(L*W): 4500*1500mm, made of SUS304 stainless steel |

Horizontal dewatering machine

Motor power: 22/37/45kw, rotation speed reach 1500rpm, get rid of water |

Drying pipe system

Heating power: 36kw |

Zig zag air classify system

Remove the labels and small dirty at last step |

Storage hopper

Volume: 3m3, made of stainless steel |

Control cabinet

France Schneider contactor/ Japan Omron temperature controller/ ABB invertor |

KOOEN company more plastic recycling machine for reference

(300-2000kg/h)PE/PP film washing line (with squeezer machine)

|

(300-2000kg/h)PE/PP film washing line (with centrifugal dryer)

|

(300-2000kg/h)HDPE, PP bottle(hard plastic) washing line

|

(300-5000kg/h)PET bottle washing line

|

(150-1000kg/h)ZL series single stage compactor granulator

|

(150-1000kg/h)ZL series double stage compactor granulator

|

(50-1000kg/h)SJ series double stage granulator (water ring cutting)

|

(50-1000kg/h)SJ series double stage granulator (pull strip cutting)

|

(300-1000kg/h)Squeezer machine

|

(200-1000kg/h)Shredder machine

|

Turnkey project service

1. we will provide all the machines for the complete production according to customer's requirements.

2. we will provide complete service for factory layout and other information to help customer to build the factory.

3. we will provide good service for machine installation and training, until the customers can run the machines and make stably production.

4. Except one year quality guarantee, we will provide after-sell service for all the life.

5. for long-term cooperation, we always provide good quality, good price and good service to customer.

Похожие товары

Большая машина для переработки пластика/высокопроизводительная машина для разрезания пластиковых бутылок, разрезания губки

Комбинированная дробилка для подготовки образцов, одобренная CE

Смарт-часы с поддержкой Bluetooth пульсометром

TOLKAR Vela высококачественные Гладильные системы с подогревом для плоской поверхности и

Гофрированный оцинкованный лист 610gr m2 gi, лист железа, лист gi 1,2 мм

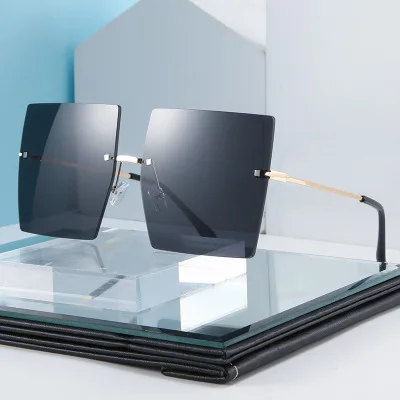

Модные Винтажные солнцезащитные очки без оправы с кристаллами Новинка большой оправой женские

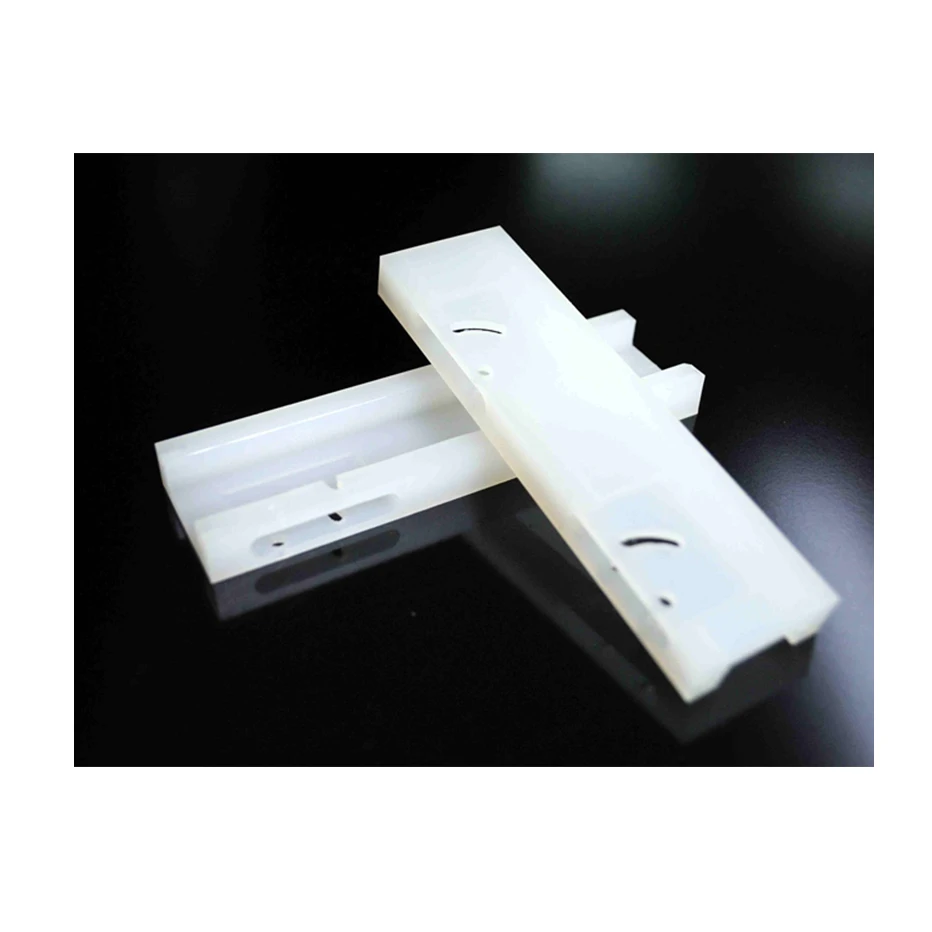

Обработка осмотической обработки, индивидуальное пластиковое сырье, пластина механического датчика, прототипы деталей автомобиля, автомобильный отражатель

Новые поступления

Новинки товаров от производителей по оптовым ценам