HLSG 600 органическое удобрение машина для мокрой грануляции быстрый смеситель гранулятор

- Категория: >>>

- Поставщик: Wenzhou Liangke Machinery Co. Ltd.

Сохранить в закладки 62291213477:

Описание и отзывы

Характеристики

HLSG-600 organic fertilizer wet granulation machine rapid super mixer granulator

Working Principle

The whole process consists of two procedures: mixing and granulating.

The adhesive is charged into the material pot from the conical hopper. Along with the filling of adhesive, the powder raw materials keep rotating in the pot under the action of stirring paddles once the hopper is closed. In the meanwhile, they grow up the shape of liquid bridge under continuous effects of conical wall. Under the action of extrusion, friction as well as kneading by paddles and conical pot wall, all materials gradually turn loose and soft. At last, open the material outlet and the wet granules will be pushed out under the centrifugal force of paddles.

The soft materials are granulated via the granulating cutters but not the forced extrusion, which will be cut into tiny and uniform granules under the semi-fluid state, realizing the mutual transformation between two different materials.

Application Examples

Mixing powder with powder (high precision and uniform)

Granulating powder with adhesive (for dense granules)

Main technical parameters

Model | HLSG-600 | HLSG-400 | HLSG-300 | HLSG-200 |

Total Volume | 600L | 400L | 300L | 200L |

Working Volume | 150-400L | 100-280L | 80-220L | 60-150L |

Material input quantity (material density is 0.5 g/ml) | 75-200KG/batch | 50-140KG/batch | 40-110KG/batch | 30-75KG/batch |

Operating time | Mixing about 2 minutes, granulating 7-14 minutes/batch | |||

Finished granule size | About Φ0.14-Φ1.5mm (12-100 meshes) | |||

Mixing motor | 30KW | 22KW | 18.5KW | 15KW |

Speed of stirring paddle | 25-220 r/min | 25-220 r/min | 25-220 r/min | 30-260 r/min |

Granulating motor | 11KW | 7.5KW | 5.5KW | 4KW |

Speed of granulating blade | 50-3000 r/min | 50-3000 r/min | 50-3000 r/min | 50-3000 r/min |

Outline dimension (L×W×H) | 2980×1200×2500 mm | 2420×1060×2150 mm | 2420×1060×2150 mm | 2180×810×1950 mm |

Weight | 3880 kg | 1900 kg | 1800 kg | 1350 kg |

Q1:Are you manufacturer or trading company?

A1: We are manufacturer with own factory and exporting department.

Q2: What does your factory manufacture?

A2: We are mainly engaged in pharmaceutical machines, including wet granulator, roll compactor, fluid bed dryier, mixer, tablet press, film coating machine, capsule filling machine etc.

Q3: What’s the lead time of your machine?

A3: Normally it’s about 30~45 working days.

Q4: What’s the payment terms?

A4: 30% deposit TT, 70% paid before shipment; or L/C, Western Union.

Q5: Can we check machine before order?

A5: Yes, welcome to visit our factory and check machine anytime.

Q6: What you can do for us if machine has problem at our factory after order?

A6: At first, please send us the report and video showing the problem, we will help solve it through the information you provide, and if need any spare parts, we will send to you by international express. If can’t solve it well, then we will dispatch our engineer to your site and check & solve the problem.

Похожие товары

Новое поступление CSR8635 Bluetooth 4,1 аудио стерео модуль

Большой емкости моющее средство порошок смеситель металлические гранулы промышленный Блендер Машина

Катушка статора Magneto, высококачественный генератор, катушка статора магнитного двигателя, подходит для двигателя Lifan 70cc-125cc, для внедорожного мотоцикла

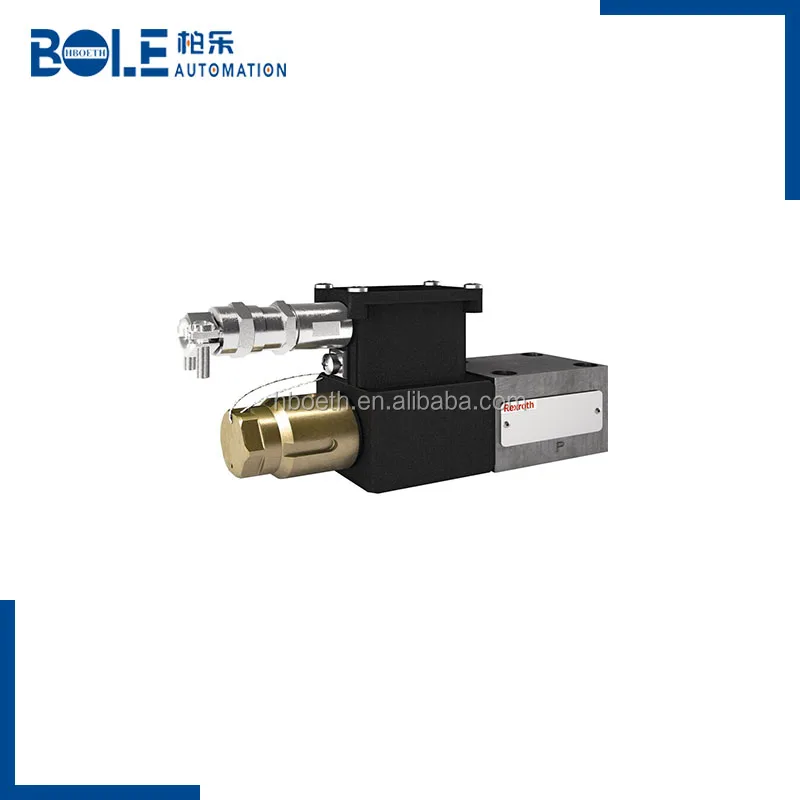

Rexroth 3 фрез серии гидравлический пропорциональный клапан с контролем потока Индуктивный датчик положения

Nrf52832 Chipset Multiprotocol Bluetooth 4.2/ant Bluetooth Beacon Module For Asset Tracking

Высококачественный 1 мл атомайзер вейп ручка упаковка оптом 510 cbd картридж капельный наконечник

Высокоскоростной медицинский гранулятор, машина для мокрой грануляции, фармацевтический Осциллирующий гранулятор для изготовления желаемых гранул

Новые поступления

Новинки товаров от производителей по оптовым ценам