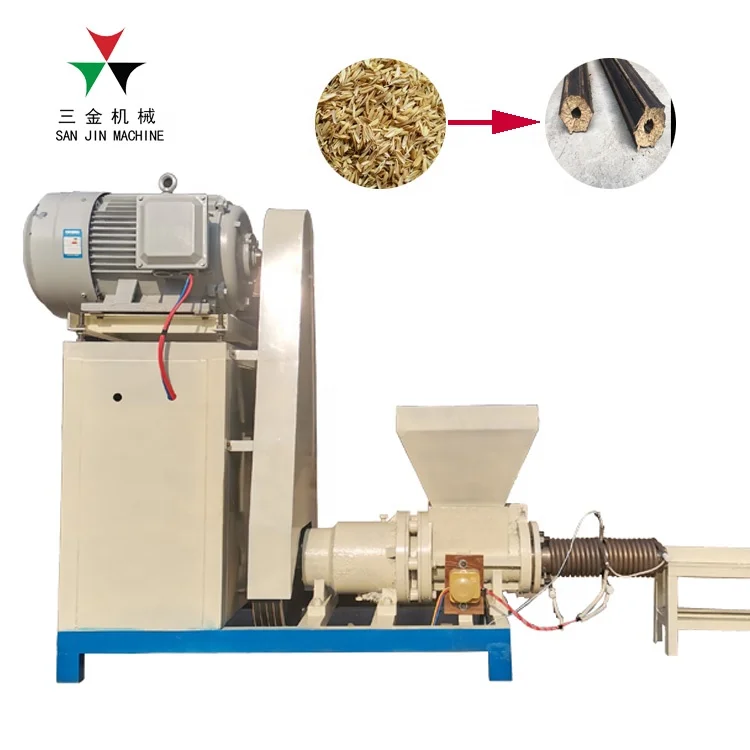

Новый компонент двигателя для производства коксовых гранул и порошка

- Категория: >>>

- Поставщик: Henan Lanyu Machinery Equipment Co. Ltd.

Сохранить в закладки 62296603685:

Описание и отзывы

Характеристики

Lanyu New Coke Pellet & Powder Pressing Machine Core Engine Component for Manufacturing Plant Coking Coal Briquette Machine

This paper delves into the creation and functioning of a mineral powder briquette making machine. This system utilizes equipment that facilitates in the formation of different types of ore powder materials, specifically those categorized as briquettes. The equipment, ore powder briquette machine, is primarily utilized for the briquetting and formation of various types of ore powder materials. The term "ore powder" generally denotes the powdery material obtained by grinding mined ores such as iron ore powder. These powders are categorized into different types based on their iron content following the process of grinding and magnetic separation. For example, limonite, magnetite, and other types of iron ores may undergo these processes before turning into ore powder bodies. This technology also contributes to national energy-saving and emission reduction projects, as it effectively recovers and utilizes various mineral powders. This, in turn, supports environmental protection efforts. The process of forming these briquettes through various mineral powders is a crucial aspect of these energy-saving and emission reduction projects. The advantage of the ore powder ball briquette lies in its reliable quality and its ability to be utilized for a wide range of applications. The machine effectively creates strong briquettes suitable for companies of various sizes, including large, medium-sized, and small-scale enterprises. This system can be used for multiple purposes, such as in industrial gas, boiler systems, and even for the recovery and utilization of various materials in different industries like metallurgy, refractory materials, and medicine.

The long-established ore powder ball briquette has garnered substantial industry recognition for its efficiency, engineering prowess, and innovation over the years. In comparison to similar products, it exhibits significant advantages, including a high ball forming rate, low energy consumption, and a structurally compact design, providing easy maintenance and adjustments, thereby maximizing productivity. The principle behind the functionality of the ore powder ball briquette is rooted in the intricate workings of the molding process, where the wheel, as the core component, plays a vital role. The two wheels, of equal diameter and parallel axes, are characterized by a regular configuration of hemispherical fossae, which ensure a uniform and consistent shape across their surface. Upon activation by the motor, the pair of wheels synchronize in rotation, moving at the same speed and in opposite directions. As the material passes through the junction of these wheels, it is subjected to compression and volume reduction, a process attended to by the formation and compaction of the ball. Continuous rotation of the wheel results in a gradual narrowing of the ball/socket distance and thus, application of greater forces, ultimately leading to enhanced compaction and formation of a stable briquette. In the course of its operation, the ball socket distance shortens, causing the briquette to form to a greater extent. After achieving a satisfactory level of ball socket distance, the wheel rotation proceeds to gradually lengthen the gap between the socket and ball. Forces applied to the briquette subsequently diminish, leading to the formation of balls of uniform size and shape for the continuous production of briquettes. The ore powder ball briquette has particular requirements when it comes to the processing of materials: 1. Materials must be no larger than 80 mesh to 200 mesh in size to ensure proper compaction and efficient production rates. 2. Refraining from incorporating metals in the material is essential, as the interaction could cause damage to the roller surface. 3. The material must be compatible, enabling the successful execution of spheroidization processes. Technical personnel are advised to communicate to the user that when using metal-containing ore powder in the production of briquettes, rolling resistance is heightened. In particular, users should be cautioned against the severe wear of the roller skin caused by metal-containing material and should consider choosing wear-resistant alloy forgings when selecting the machine. In summary, the ore powder ball briquette has had a significant impact on industry, primarily due to its energy-efficient, compact design, and smart adaptation to specific material requirements. Its success relies on the principle of utilizing the core component, the wheel, which is precisely tailored to mold various materials effectively. Incorporating appropriate material composition and processing restrictions, the ore powder ball briquette remains a highly sought-after technology in a wide range of industrial applications.

Briquette machine can be used to suppress pulverized coal, iron, coal, aluminum, iron, iron oxide, carbon powder, charcoal powder, slag, gypsum, tailings, sewage sludge, kaolin, activated carbon, coke powder and other powder, powder, waste, waste residue, and it’s widely used in refractory, metallurgical, chemical, electric factory, energy, transportation, heating and other industries.

Briquette machine can process raw materials into corresponding pillow, oval, round or square shaped end products.

Working principle of ball press machine

1. Raw material is transferred onto two pressure rollers of ball press machine through feeder.

2. Raw material enters the ball roll mode with the roll rotation.

3. Material pressure on a small part become larger, when the material enters into the two pressure rollers, the pressure of materials has reached the peak.

4. Tremendous pressure between the two rollers, the powder become finished product.

Performance Features

Briquette machine is mainly used for the pelleting of powdery materials that are difficult to be pressed and it has such features as high pelleting pressure, adjustable rotating number of the main engine and configuration of spiral feeder machine.

The Materials Size Requests for Briquette machine

In order to ensure the good quality and mechanical strength of the final product, special care should be taken to ensure that the granule size fed to the machine is maintained below 3mm, preferably in the range of 30-40% smaller than 1–2 mm, with no more than 10% over 2 mm.

Briquette machine can suppress all kinds of powder materials like magnesia, bauxite, dolomite, iron powder, lignite, coal powder, iron powder, coking coal, aluminum, iron, tin oxide, carbon powder, coal powder, slag, gypsum, tailings, sludge, kaolin clay, activated carbon, coke, etc, with forced pressurization method

Who we are

Established in 1980, Henan Lanyu Machinery is a professional the sawdust briquette machine manufacturer based in Henan Province. Every year, we exported hundreds of the sawdust briquette machine to Sudan, Egypt, and Zimbabwe etc.

l What we do

We are specialized in manufacturing and exporting different models of the sawdust briquette machine, carbonization equipment and many other related the sawdust briquette machineproducts.

l Why us

We use stringent quality control measures to ensure the reliability of our products. Our products including the sawdust briquette machine have gained CE and ISO 9001 certificate guarantee. With sound business credit, rich experiences, excellent after-sales services and modern manufacturing facilities, we’ll cooperate with and serve you better.

Q1: Can you test our sample raw materials on your ball press machine?

Yes, we are very happy to receive your sample materials for testing and analysis.

Q2: Do you provide equipment operation training for your customers?

Yes. We can send professional engineers to your site for equipment installation and commission, also giving operation and maintenance training. We could also provide training online to your staff. The third option is sending you videos to guide you on installation and operation.

Q3: Could you offer the complete wood working flow chart?

A: Yes, we will allocate suitable production chart according to your special requirements, such as crusher, wood hammer mill, carbonization furnace, ball press machine, dust-removal device, auto-feeding conveyor, discharging conveyor, and control cabinet etc.

Q4: Where is your factory located? How to get there?

A: We are located in Zhengzhou city, Henan province, China. The nearest airport is Zhengzhou Xinzheng International Airport, and the Airport Code is CGO. We will pick you up at airport. Welcome to visit our factory anytime.

If you require further information about ball press machine, please feel free to contact me. Welcome to visit our factory anytime!

Похожие товары

Простая гидравлическая машина для прессования кокса мини угольный Овальный брикет экструзии угольных стержней из Китая

Промышленная соляная шариковая машина хлорид натрия морская содовый блок карбонат формовочное оборудование

Электрическая машина по производству древесины бамбука кокосовой скорлупы древесного угля брикетов заводской цене

Бамбуковый Станок Для Брикетирования Древесных Опилок

Пресс-машина для шара

Заводская цена сельскохозяйственные отходы солома кукуруза Боб древесные опилки брикетировочные стержни пресс-машина производственная линия

Брикетировочная машина для кальяна

Новые поступления

Новинки товаров от производителей по оптовым ценам