Индивидуальный Cbn трубчатый хонинговальный станок инструмент для отверстий в редукторах cbn камень 6 35x6 35x203 мм

- Категория: Abrasives >>>

- Поставщик: Shanxi Bigstars Superabrasive Tools And Products Co. Ltd.Shanxi Ltd.

Сохранить в закладки 62307444738:

Описание и отзывы

Характеристики

We offer a full range of diamond honing stones, CBN honing stones, honing tools, mandrels, honing head, adapters,wedges, retainers and centering sets.

At the moment, honing stones we produced can be equipped for most of home and abroad honing machines. Our superabrasive honing stones are designed for America SUNNEN; Germany GEHRING, NAGEL; Japan CHISHIMA , TOYO , NISSIN and some other honing machines. We can develop abrasive stones for special purpose as per the customer’s requirements.

Application and performance

| CBN honing stones | Diamond honing stones | ||||||||

| Application | Rigid steel, alloy,etc. | Glass, quartz, rigid alloy, cast iron, ceramic materials, etc. | |||||||

| Performance | High strength and hardness, suitable for all hard materials | High strength and hardness, suitable for all non-carbide hard materials | |||||||

Grain size and roughness

| Material | Honing stone type | Abrasive grain sizes | ||||||||||

| 80 | 100 | 150 | 220 | 280 | 320 | 400 | 500 | 600 | 1200 | |||

| Rigid steel | CBN | — | 1.40 2.00 | 1.15 | 1.00 | 0.70 | — | 0.50 | — | 0.18 | 0.05 | |

| Mild steel | CBN | — | 1.60 2.50 | — 2.00 | 1.25 | — | — | 0.65 | — | 0.40 | 0.12 | |

| Cast iron | Diamond | — | — | — | 2.00 | — | — | 1.27 | — | 0.50 | 0.30 | |

| Hard alloy | Diamond | — | — | 0.75 | 0.50 | — | — | 0.18 | — | 0.08 | 0.03 | |

| Ceramic | Diamond | — | — | 1.27 | 1.00 | — | — | 0.50 | — | 0.40 | 0.25 | |

| Glass | Diamond | — | — | 2.40 | 1.80 | — | — | 0.75 | — | 0.40 | 0.20 | |

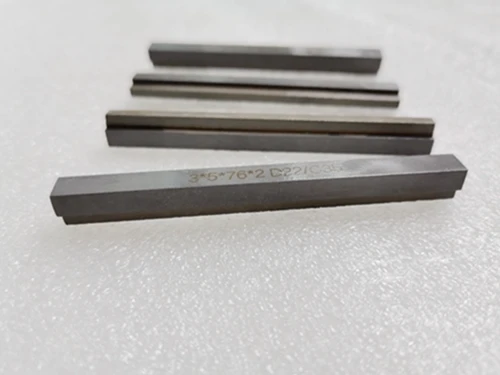

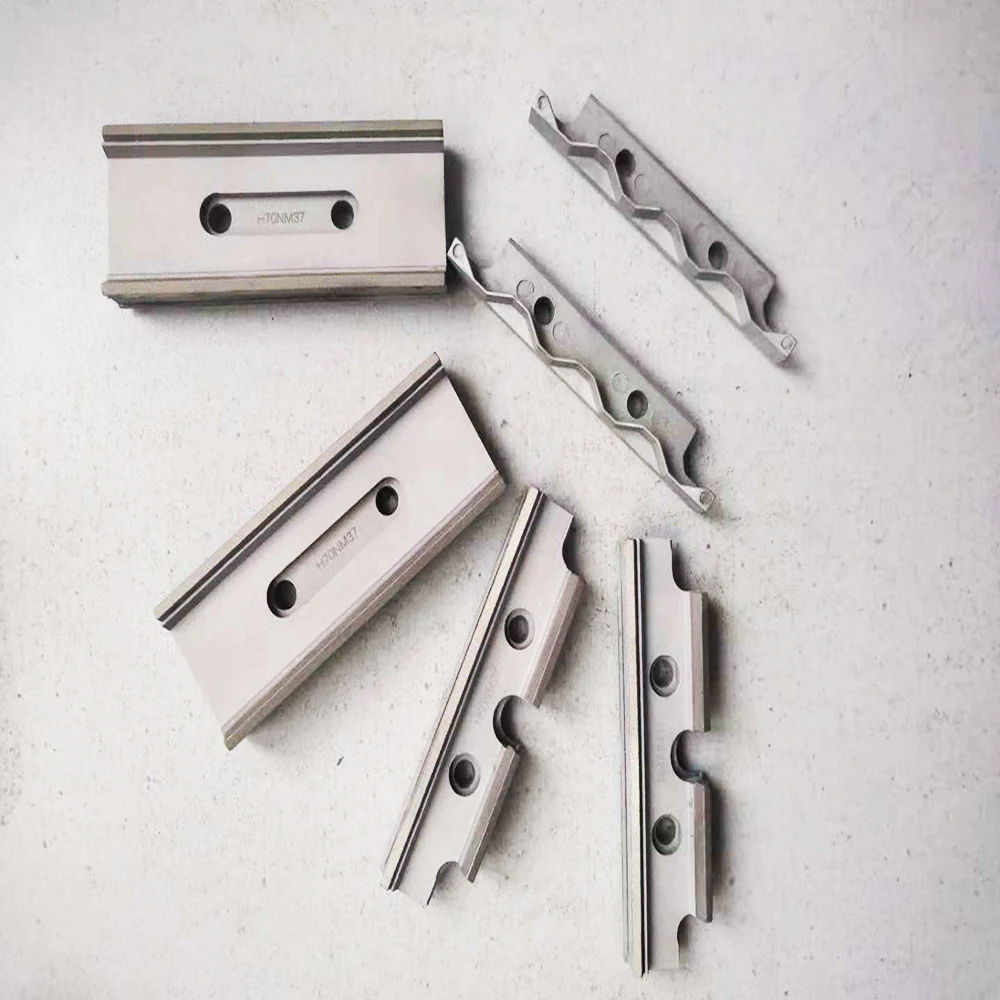

Honing stones

Honing stones

Honing head and honing stone

Bigstars superabrasive tools and products Co., Ltd

"Cross-hatch" pattern expert: professional at manufacturing cylinder block&liner and honing stones

In recent years,"cross- hatch" pattern on cylinder bore honing as a new technology of finish machining is widely used. Not only reliable accuracy and performance is ensured, but also efficiency is improved and cost is reduced.

"cross-hatch " pattern honing is to create tiny grooves on the surface of cylinder bore by honing .These grooves are regulrly arranged to form "cross-hatch"pattern . The peaks of grooves are cut off by special honing technology to form tiny plateaus. This structure consists of deep grooves with oil storage function and tiny supporting plateaus among grooves,which is typical "cross-hatch"pattern honing surface.

This typical structure formed by "cross-hatch"pattren honing on the surface of cylinder bore has following advatages

1. Tiny plateaus increase the contact area . By cutting off the peaks ,early rapid wear is eliminated and wear-resistance is improved.

2.Tiny grooves make good oil-reservation ,and oil film is formed on the surface of cylinder,which reduces the friction among cylinder bore surface , piston and piston ring. So piston ring of low friction can be used.

3.Good oil-reservation by tiny grooves ,which decreases the loss of oil and oil consumption.

4.Countless tiny plateaus are formed on the surface of cylinder bore after honing , so the contact area among cylinder bore , piston and piston ring is increased and the support of cylinder bore surface is increased as well. This reduces initial wear and run in time(almost saved)

The basic technology of "cross-hatch" pattern

The process of "cross-hatch"honing is" rough honing ⇒ fine honing ⇒ plateau honing"

Comparison of plateau honig and ordinary honing

The following graphs show surface profilogram of two times common honing and cross-hatch pattern honing. Fig2 is the micro structure by plateau honing, from which we can see its structure is obviously improved than common honing . It has plateaus of high support rate and deep groove structure for oil reservation.

1. Platform textured effect Platform for honing the surface of the textured microstructure

2. 40°—60° (100times)

At Present, our compamy has developed honing stones of EU III, EU IV standards for home and abroad engine manufacturers .Such as, Cummins Steyr, Reymolds Wei chai, Xi chai , Yu chai ,Chao chai ,etc.We could develop honing stones for special purpose to meet customer's special needs.

Sunnen H70A63 honing stone Sunnen P28DM55 honing stone H70 CBN honing stone Sunnen K12NM55 honing stone

| Packing | Carton, plastic bag,or as your request | ||||||

| Shipping | we use DHL,UPS,FEDEX,ect.to ship the goods,or according to the customer's requirement | ||||||

| Delivery time | about3-7days, for special time according to your quantity | ||||||

1. Quick Response: Your inquiry will be replied within 24 hours.

2. Competitive Price : Directly from factory to save your money.

3. after-sales warranty : Once there is problem after you received products, you can contact us in time. We will resolve it in short time.

4. Flexibility: Small orders are acceptable for quick delivery and to help you reduce stock cost.

5. OEM service: Custom fabrication according to your drawings ,samples or designs.

Shanxi Bigstars Superabrasive Tools and Products Co., Ltd is a high-tech company engaged in R&D, manufacture of superabrasive grinding wheels, superabrasive honing stones and tools, etc. In absorption of advanced overseas superabrasive material technological theory, we launched series of superabrasive products and tools that our customers and industry peers to be the unanimous endorsement. Our aim is to become an excellent enterprise which is working on superabrasive tools and products, and we can also provide customers with.

Technology creates high-quality goods, profession is creditworthy.

1. Are you a manufacture supplier?

YES, we are a professional manufacture with 13 years of production in making series of honing stones and superabrasive grinding wheels.

2. How about your shippment time?

For normal order: within 5-7 days.

For large quantity: within 10-15 days.

3. How to make an order?

Our honing stones and honing mandrels can be used on Sunnen, Nagle, Gehring, Nissin,Chishima, J&S honing machines.

Customized honing stones, honing tools are available. PLS provide the following information:

Honing machine model: (horizontal or vertical)

Bore type:(open through bore, blind, etc.)

Bore length:

Start diameter and finish diameter

4. How about your shippment way?

We will select suitable shippment according the order quantity, the package details shippment by express(TNT, DHL, FEDEX, USP),by air or by sea.

5. How do I make payment?

We will make PI for you, you can make payment with L/C, T/T, Western Union,Paypal.

Any products you have interest, PLS feel free to contact me at any time

Похожие товары

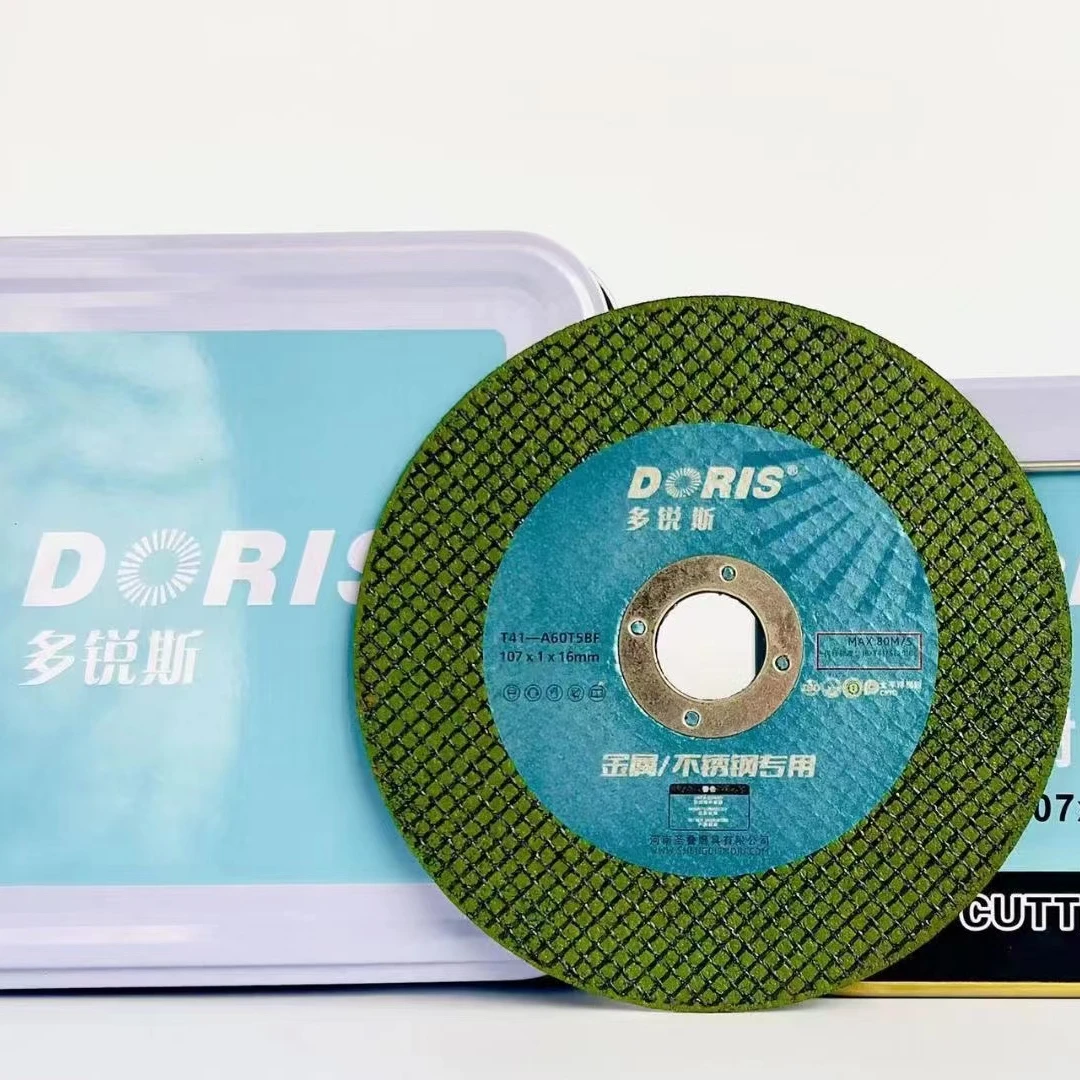

Лидер продаж, 4,5 для полировки металла \

Алмазный дисковый стальной вращающийся режущий инструмент 10 шт. круговой абразивный небольшой мини-алмазный пильный диск

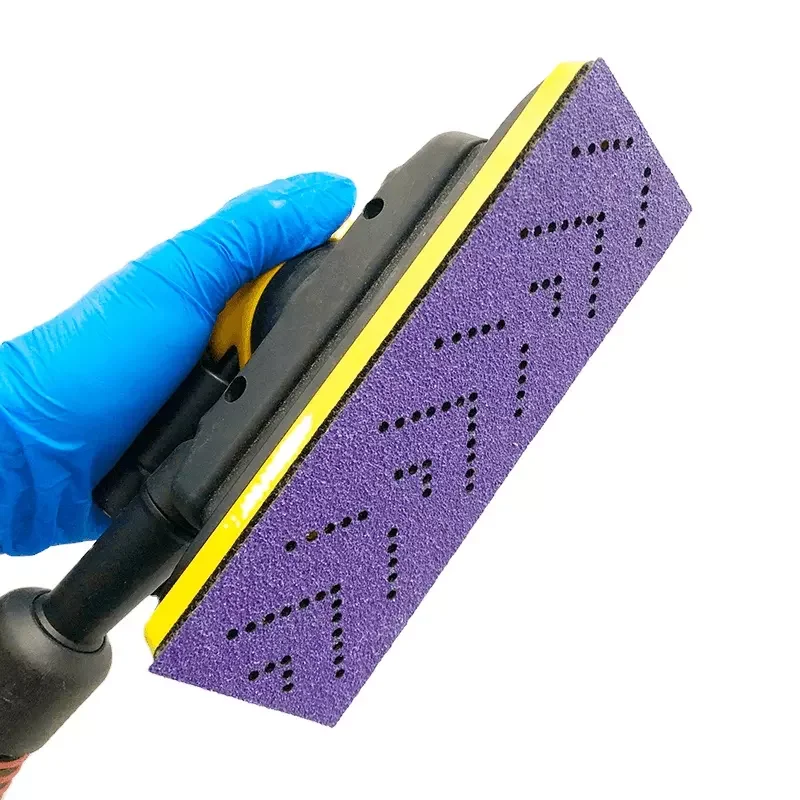

Абразивные ленты 70x198 мм, наждачная бумага, пленка для подвала, керамическое зерно, антиблокировка, шлифовка и полировка автомобильной краски

Заводская поставка, двусторонняя наждачная бумага 100x120 мм, зернистость 60-240, полировальная губка для шлифовки и шлифовки наждачной бумаги

Абразивный алмаз 6 # Soft Bond для бетона с системой Redi-Lock

Набор абразивных камней для Dremel 4000 3000, 4/5/6/8/10 мм, 10 шт.

Цена производителя абразивный режущий диск 5 дюймов 9 дюймов металлический режущий диск для резки нержавеющей стали

Новые поступления

Новинки товаров от производителей по оптовым ценам