Центробежная центрифуга с декантером для обезвоживания осадка разделения твердых и жидких

- Категория: Separation Equipment >>>

- Поставщик: Zhengzhou Toper Industrial Equipment Co. Ltd.

Сохранить в закладки 62345811113:

Описание и отзывы

Характеристики

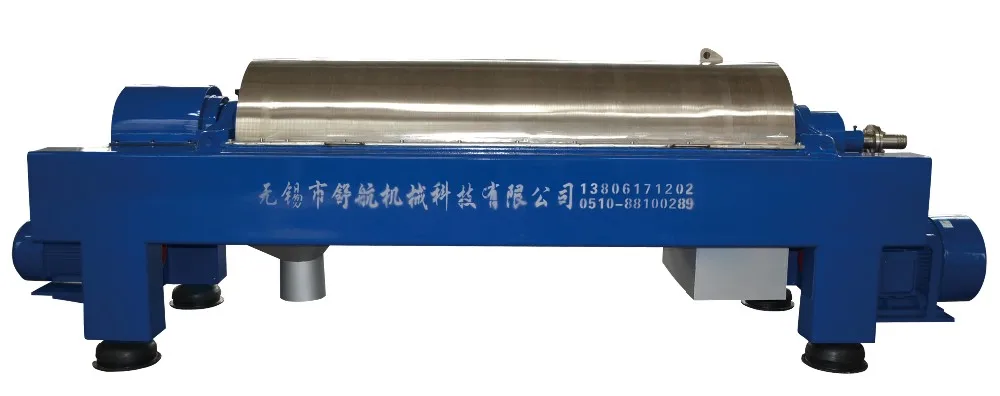

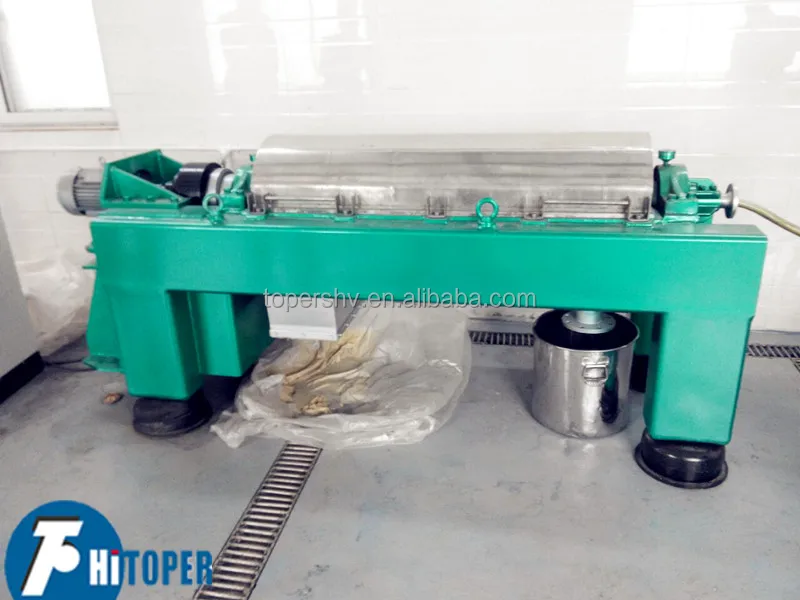

Sludge dewatering decanter centrifuge force for separation solid and liquid

Operating Principle:

Separation takes place in a horizontal bowl equipped with a scroll conveyor. The process material is fed into the bowl through a stationary inlet tube and is smoothly accelerated in the accelerate chamber. Centrifugal forces cause instant sedimentation of the solids on the wall of the bowl. The conveyor rotates in the same direction as the bowl, but at a different speed, thus moving the solids towards the conical end of the bowl.

Strcture and Working Principle:

Process advantages of Horizontal Decanter Centrifuge:

Process flexibility

Constant separation results, even at fluctuations in the volumetric flow, the process conditions, or the product characteristics

Process conditions

1)gas-tight, vapor-tight, or pressurized operation

2)low vibration levels

3)absolute pressures from 0 to 8 bar

4)-90° C to +200° C

5)CIP cleaning

6)flameproof or explosion-proof standards making the decanter ideal for applications with solvents and hazardous materials

Cemical resistance

Materials such as titanium, pure nickel, or Hastelloy provide the security essential in demanding process applications.

Low space requirement

1)compact design at high specific throughput

2)self-contained system, therefore no extra space required for peripheral equipment

Low operating costs

Operating consumables (e.g. filter cloths) are not required. No costly downtime for changing consumables.

Simple installation

1)integration of all necessary functions in one package (e.g. no need for peripheral equipment)

2)active support system (no foundations)

Clarification

Clarification is the separation of solids from a liquid of lower density over a particle size range from 1 to 10,000 microns.

By increasing the centrifugal force, it is possible to also separate very small particles in the submicron range, even with very small differential density.

Classifying

By controlled reduction of the residence time, classification according to particle size, down to the submicron range, can be achieved with sharp separation cuts.

Liquid/liquid separation

Liquid phases of differing densities can also be separated.

Thickening

Fine solids separated from the liquid can be thickened in a hindered settling mode, utilizing the volume of the cylindrical section of the decanter to maximize compression.

Compression

Compactive dewatering provides a substantially higher degree of dewatering with compressible solids.

Washing

Efficient and cost-effective counter-current washing is made possible by separate removal of the wash liquor over several sections of the screen.

Dewatering

The solids dewater by a combination of drainage and compression. The degree of drainage/compression depends on the nature of the solids, the setting of the centrifuge, and the required degree of dewatering. The transport and discharge of pasty, sludge-like or shear-sensitive solids are facilitated by the appropriate combination of conveyor geometry, cone geometry, and control of the differential speed.

Mixing and re-suspension

Special solids discharge geometry (gutter) allows the dewatered solids to be mixed with liquid directly at the discharge, thus eliminating the need for an additional mixing vessel.

Major applications:

Main technical parameters:

More photos:

FAQ:

Q1.What’s your advantage? Why we choose you?

A:1)10 Years experience of centrifuge production and R&D.We have the most professional techniques and team. More advantage in price

2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized include package.

3)We use 100% new materials and the best production process

Q2.What’s the Payment?

A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the

procedure is complex and the fee is high. You can also use Western Union and Paypal.For large

quantity,sea shipping can be provided.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

How long is the warranty period ?

12 months.

Our Services:

Sludge dewatering decanter centrifuge force for separation solid and Sludge dewatering decanter centrifuge force for separation solid and liquidliquidRiver

ud dewatering decanter centrifuge

River mud dewatering decanter centrifuge

Похожие товары

OEM нержавеющая сталь 45 кг Excalibur сушилка для растений мяса овощей фруктов осадка оборудование

Декантерная центрифуга для Непрерывного разделения

Литий-ионный сепаратор батареи Хорошая цена на лист полипропиленовой пленки

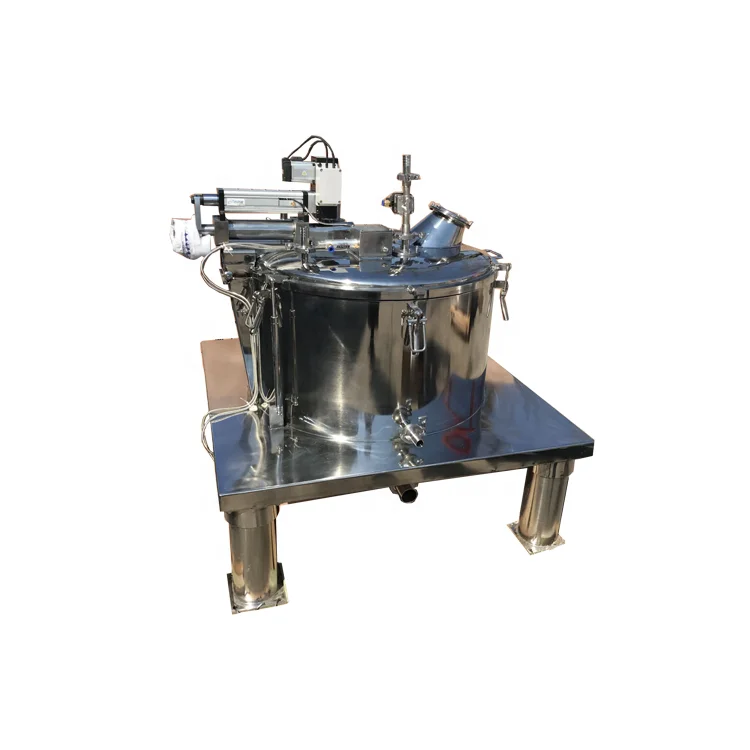

Высококачественный корзинный фильтр, сепаратор конопляного масла, центрифуга для разделения твердых жидкостей от производителя

Автоматическая дисковая центрифуга для дрожжевых бактерий

Плоская пластина пластиковый минеральный сепаратор промышленный экстракт центрифуга сделано в

Профессиональный Производитель 2 Фаза фильтр разделения Автоматическая непрерывная ЦЕНТРИФУГА МАШИНА для ферментации

Новые поступления

Новинки товаров от производителей по оптовым ценам