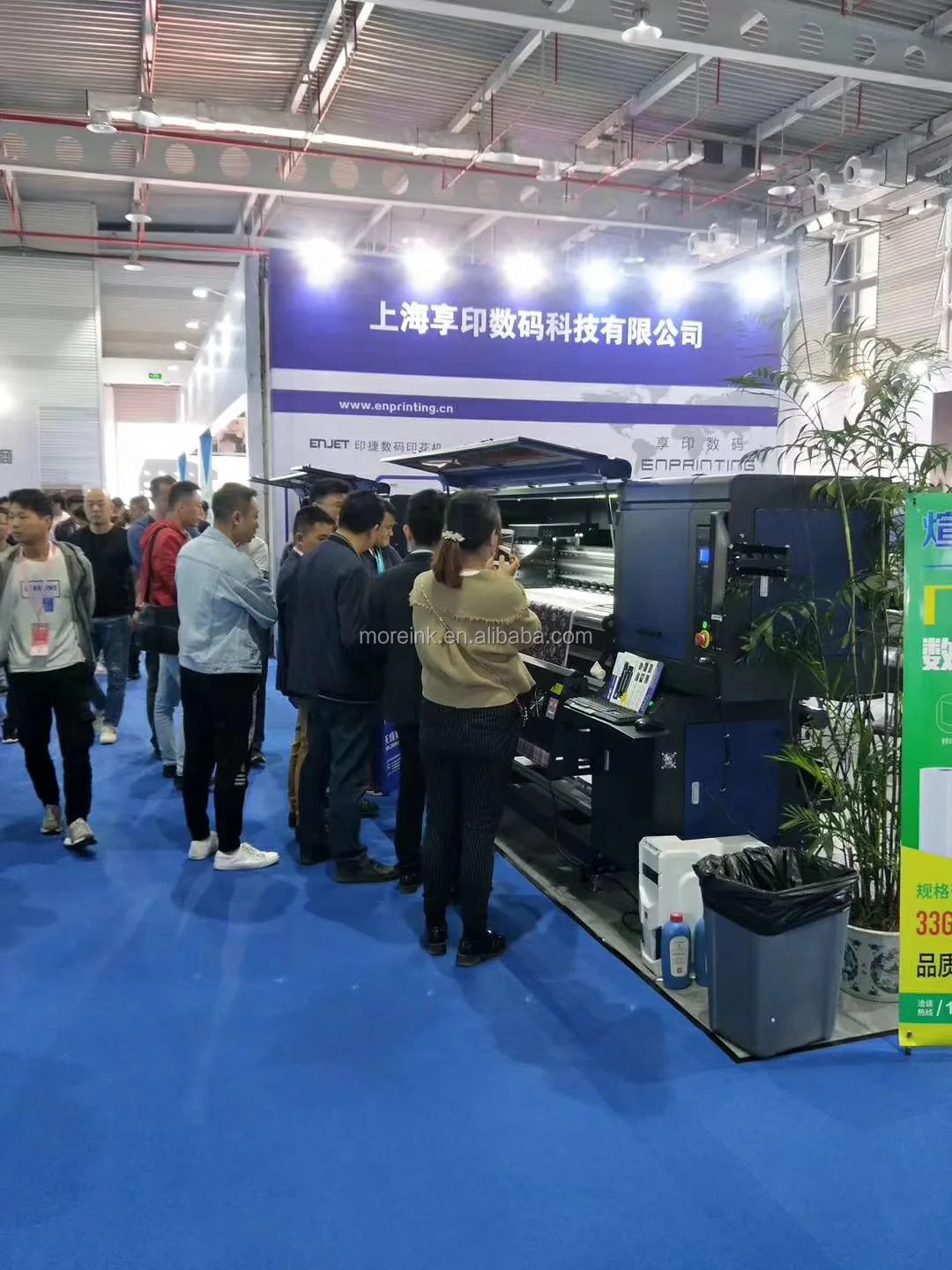

High Speed Roll-to-roll Dye-sublimation Printer:1. Outstanding printing speed and precision, excellent reliability and stability

2. Advanced industrial design, high-efficiency date processing technology

3. Strong R&D team with rich professional experience and 27 patents

4. Responsible worldwide service team provides quick answers to your questions and concerns

5. A cost-effective machine brings customs more profit and return

Feature:

High speed:

2 pass 140㎡/hr; 3 pass 95㎡/hr; 4 pass 72㎡/hr

High quality printing, creates greater value for customers:

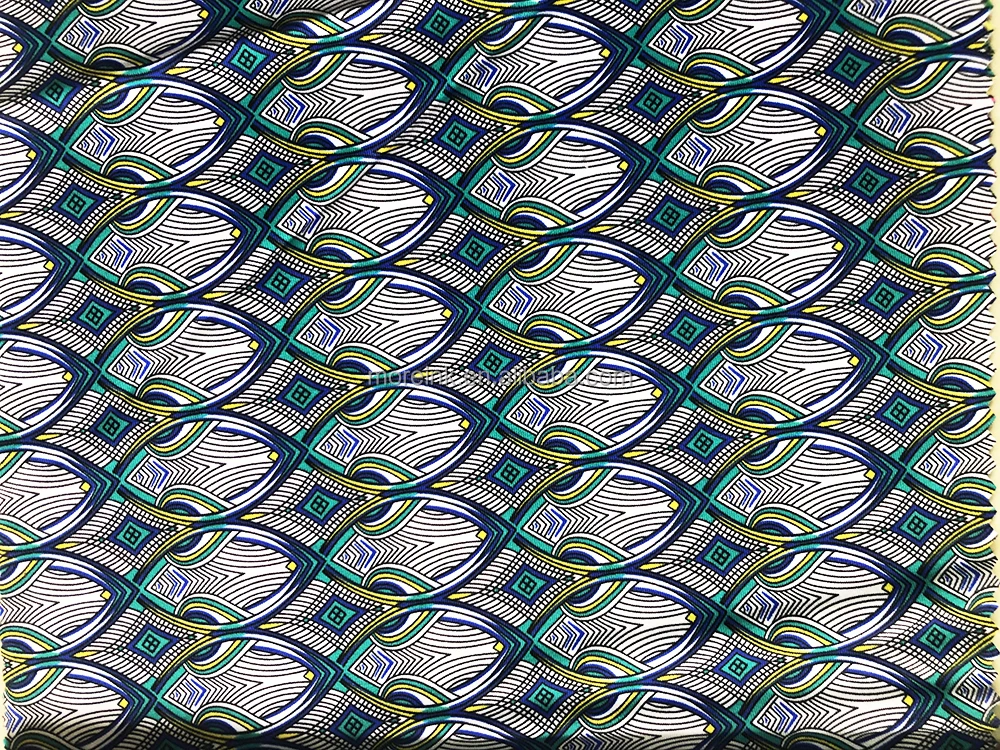

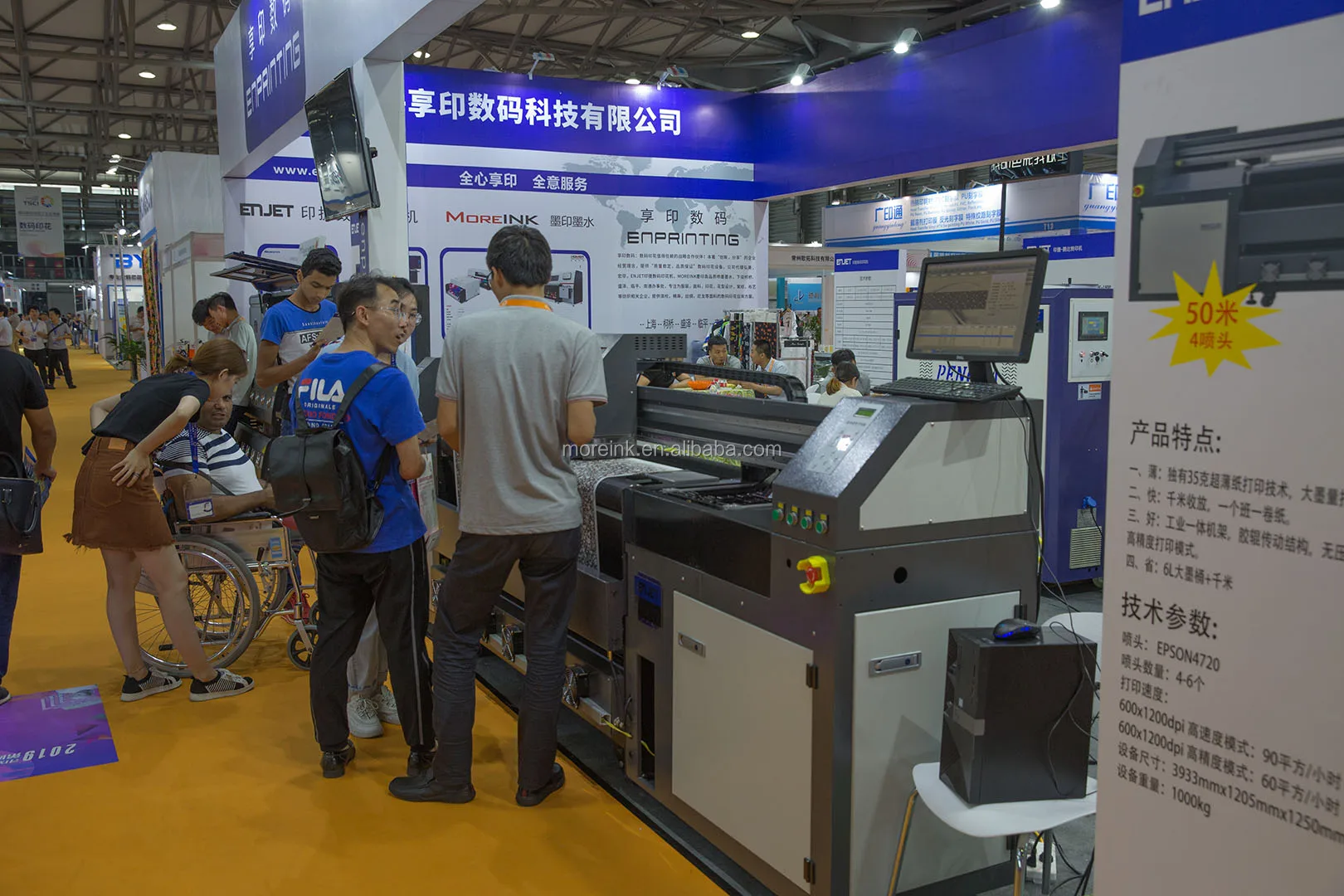

1. Equiped with industrial-grade kyocera printheads, supports 4-8 colors printing, resolutions can be as high as 600x1200 dpi for high quality pictures.

2. Combining self-developed hardware and software system with advanced mechanical techniques, the machine delivers printing speeds of up to 140㎡/hr.

3. Visible and smart user interface enables one operator to manage multiple machines. Skill training can be easily accomplished.

4. Variable droplet printing technology is applied for control on ink drop size, to achive enriched image reproduction.

High-end design for industrial production:

1. Adjusting the tesion of the winding media by manually increasing or decreasing the standard counterweights to adapt to different ink volumes and media.

2. 4-8 colors inkjet solutions improve adduracy of drop locations and gurantee the printing quality.

3. Excellent printing quality is also ensured by extraordinary color fastness, bright colors, and stable and smooth inkjet printing.

4. Eco friendly ink is used for green priting, good for now and for the future.

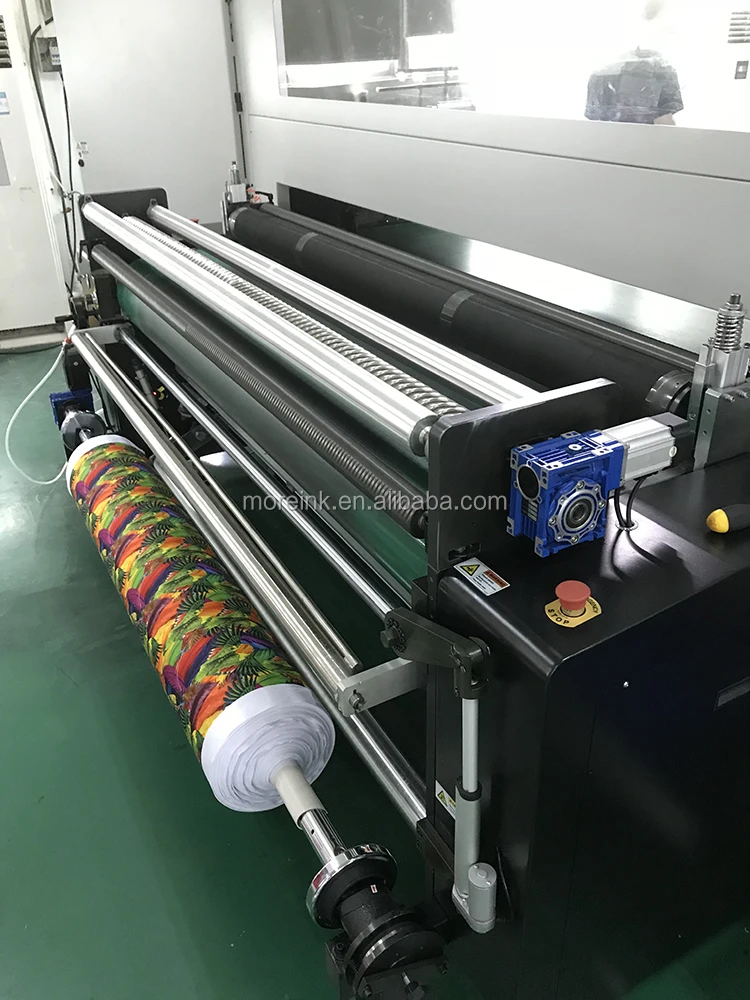

5. The structure of integrated steel frame achieves high stability, high compression resistance and good wear strength. The scientific roll-to-roll design facilitates high productivty.

6. Two drying modes are available, front drying and bottom drying. The front drying+botton drying is suitable for heavy ink printing. The front drying is controlled manually. It can be turned off for ordinary patterns to save energy.

Digital printing, rapid response:

1. Print on demand, low energy consumption and environment-friendly.

2. Efficient combined output of short orders and rush orders, quick response to market demands.

3. Powerful order management functions: orders can be automatically saved, easily modified or retrieved. High efficiency contributes to optimized production.

4. Flexible and convenient: no plate making; no color mixing, seamless switch between orders of same specifications. Any pattern you designed can be all easily realized.

5. Meeting demands of instant order change, fast delivery and zero inventory. New business models are created for bright future.

Protection and maintance, for longer useful life:

1. The negative pressure is controlled by real-time monitoring and adjustment technology to ensure continuous and stable printing.

2. The reliable anti-scratch design can effectively protect printheads. It minimizes the damage of fabric to the printheads and extends service years of the costly printheads.